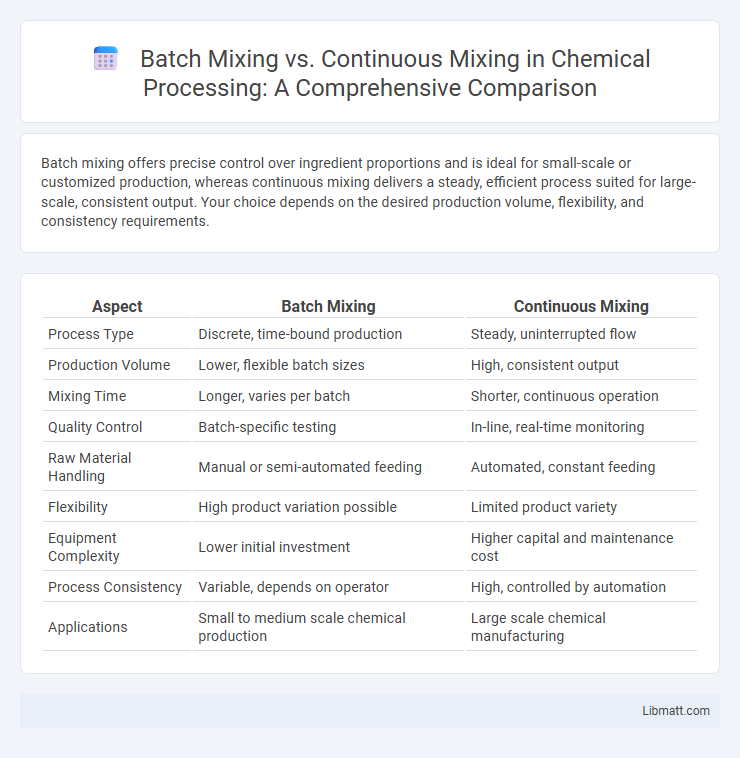

Batch mixing offers precise control over ingredient proportions and is ideal for small-scale or customized production, whereas continuous mixing delivers a steady, efficient process suited for large-scale, consistent output. Your choice depends on the desired production volume, flexibility, and consistency requirements.

Table of Comparison

| Aspect | Batch Mixing | Continuous Mixing |

|---|---|---|

| Process Type | Discrete, time-bound production | Steady, uninterrupted flow |

| Production Volume | Lower, flexible batch sizes | High, consistent output |

| Mixing Time | Longer, varies per batch | Shorter, continuous operation |

| Quality Control | Batch-specific testing | In-line, real-time monitoring |

| Raw Material Handling | Manual or semi-automated feeding | Automated, constant feeding |

| Flexibility | High product variation possible | Limited product variety |

| Equipment Complexity | Lower initial investment | Higher capital and maintenance cost |

| Process Consistency | Variable, depends on operator | High, controlled by automation |

| Applications | Small to medium scale chemical production | Large scale chemical manufacturing |

Introduction to Batch and Continuous Mixing

Batch mixing processes involve combining ingredients in fixed, discrete quantities within a single container, allowing precise control over formulation and typically used for small to medium production runs. Continuous mixing, on the other hand, continuously blends materials in a steady flow, optimizing efficiency for large-scale operations and maintaining consistent product quality. Understanding the differences between batch and continuous mixing helps you select the most suitable method for your production needs, balancing control, scalability, and throughput.

Key Differences Between Batch and Continuous Mixing

Batch mixing processes handle fixed quantities of materials in discrete lots, allowing precise control over ingredient proportions and flexibility for varying formulations. Continuous mixing operates with a steady input and output flow, enabling higher throughput and consistent product quality over time. Your choice depends on production scale, customization needs, and efficiency requirements.

Advantages of Batch Mixing

Batch mixing offers precise control over ingredient proportions and mixing time, ensuring consistent product quality and flexibility in handling diverse formulations. It allows for easy adjustment of recipes and quick changeovers between different batches, minimizing downtime in production. This advantage makes batch mixing ideal for custom production runs and small to medium-sized manufacturing processes where accuracy and adaptability are critical to Your operation.

Advantages of Continuous Mixing

Continuous mixing offers increased production efficiency by maintaining a consistent flow of materials, reducing downtime between batches. It ensures uniform product quality through steady, real-time blending and precise control over process variables. Energy consumption is optimized, lowering operational costs and minimizing waste compared to traditional batch mixing methods.

Limitations of Batch Mixing

Batch mixing faces limitations such as inconsistent product quality due to variations between individual batches and longer downtime required for cleaning and setup processes. This results in reduced overall efficiency and higher labor costs compared to continuous mixing systems. Understanding these constraints can help you decide if batch mixing is suitable for your specific production needs.

Limitations of Continuous Mixing

Continuous mixing faces limitations such as less flexibility in handling varying batch sizes and formulations, making it challenging to quickly adapt to production changes. The process often requires precise control systems to maintain consistent quality, which can increase operational complexity and costs. Your manufacturing goals may be better served by batch mixing when customization and quality control are critical factors.

Application Areas for Batch and Continuous Mixing

Batch mixing is predominantly used in industries requiring precise formulation control, such as pharmaceuticals, specialty chemicals, and food production, where small to medium quantities and frequent changeovers are common. Continuous mixing excels in large-scale, high-throughput applications like petrochemicals, plastics manufacturing, and wastewater treatment, providing consistent product quality and operational efficiency. Selection depends on production volume, process flexibility, and product consistency requirements.

Factors to Consider When Choosing a Mixing Method

Factors to consider when choosing between batch mixing and continuous mixing include production volume, product consistency, and process control requirements. Batch mixing offers flexibility and precise ingredient adjustments, ideal for small to medium-scale production or when formulations change frequently. Your choice should balance operational efficiency with quality control, ensuring the mixer aligns with production goals and product specifications.

Cost Implications of Batch vs Continuous Mixing

Batch mixing involves higher labor and downtime costs due to frequent cleaning and setup, whereas continuous mixing reduces operational interruptions and labor expenses by maintaining a steady production flow. The initial investment for continuous mixing equipment is significantly higher but leads to lower variable costs and increased efficiency over time. Batch mixing suits smaller production volumes with flexible product changes, while continuous mixing offers cost advantages in large-scale, consistent manufacturing environments.

Future Trends in Mixing Technologies

Future trends in mixing technologies emphasize the integration of automation and real-time monitoring to enhance precision and efficiency in both batch mixing and continuous mixing processes. Advanced sensors and AI-driven controls enable adaptive adjustments, improving product consistency and reducing waste. Your production facility can benefit from hybrid systems that combine batch flexibility with continuous process efficiency to meet evolving industry demands.

Batch mixing vs continuous mixing Infographic

libmatt.com

libmatt.com