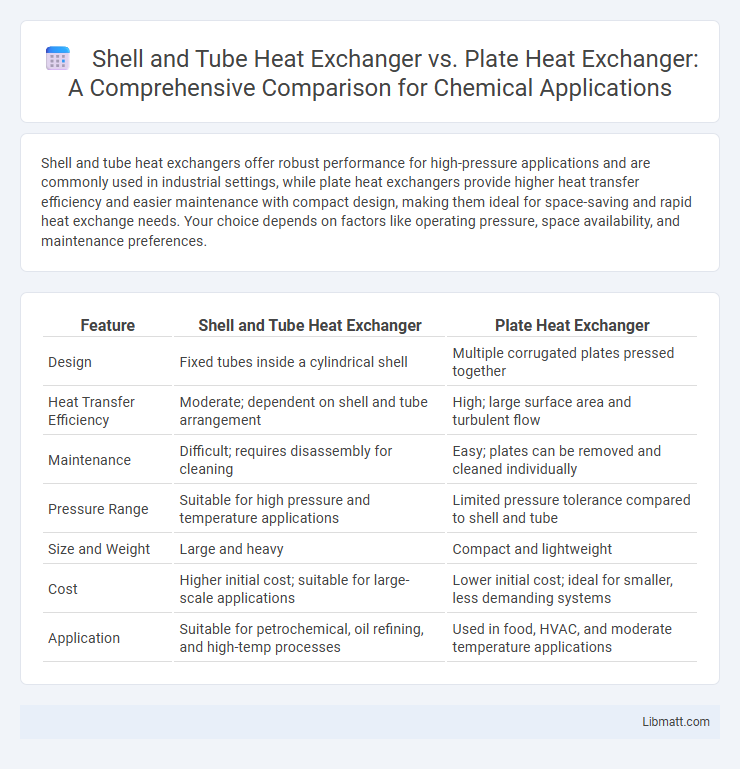

Shell and tube heat exchangers offer robust performance for high-pressure applications and are commonly used in industrial settings, while plate heat exchangers provide higher heat transfer efficiency and easier maintenance with compact design, making them ideal for space-saving and rapid heat exchange needs. Your choice depends on factors like operating pressure, space availability, and maintenance preferences.

Table of Comparison

| Feature | Shell and Tube Heat Exchanger | Plate Heat Exchanger |

|---|---|---|

| Design | Fixed tubes inside a cylindrical shell | Multiple corrugated plates pressed together |

| Heat Transfer Efficiency | Moderate; dependent on shell and tube arrangement | High; large surface area and turbulent flow |

| Maintenance | Difficult; requires disassembly for cleaning | Easy; plates can be removed and cleaned individually |

| Pressure Range | Suitable for high pressure and temperature applications | Limited pressure tolerance compared to shell and tube |

| Size and Weight | Large and heavy | Compact and lightweight |

| Cost | Higher initial cost; suitable for large-scale applications | Lower initial cost; ideal for smaller, less demanding systems |

| Application | Suitable for petrochemical, oil refining, and high-temp processes | Used in food, HVAC, and moderate temperature applications |

Introduction to Heat Exchangers

Shell and tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, allowing efficient heat transfer between two fluid streams, typically used in high-pressure applications. Plate heat exchangers utilize multiple thin, corrugated plates stacked together, providing a large surface area that enhances heat transfer while maintaining a compact design, ideal for lower pressure and temperature processes. Both types optimize thermal performance but differ significantly in maintenance, space requirements, and operational pressure capacities.

Overview of Shell and Tube Heat Exchangers

Shell and tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, allowing one fluid to flow through the tubes while another flows over the tubes inside the shell, facilitating efficient heat transfer. They are widely used in industries such as petrochemical, power generation, and HVAC due to their robust design, high-pressure capability, and ease of maintenance. The versatility in handling large volumes and significant temperature differentials distinguishes shell and tube exchangers from plate heat exchangers, which use stacked plates to transfer heat.

Overview of Plate Heat Exchangers

Plate heat exchangers consist of multiple thin, corrugated plates stacked together, enabling efficient heat transfer through a large surface area in a compact design. They are typically used for applications requiring easy cleaning, maintenance, and high thermal efficiency, such as HVAC systems, food processing, and chemical industries. Compared to shell and tube exchangers, plate heat exchangers offer greater heat transfer coefficients and are better suited for handling fluids with low fouling tendencies.

Design and Construction Comparison

Shell and tube heat exchangers feature a robust design with tubes enclosed within a cylindrical shell, enabling high pressure and temperature handling suitable for industrial applications. Plate heat exchangers consist of multiple thin, corrugated plates assembled in a frame, offering a large surface area for heat transfer with a compact footprint and ease of maintenance. The welded or gasketed plates in plate exchangers allow for efficient heat exchange but typically handle lower pressures compared to the mechanically strong shell and tube design.

Thermal Efficiency and Performance

Shell and tube heat exchangers provide robust thermal efficiency for high-pressure and high-temperature applications, with performance influenced by flow arrangement and surface area. Plate heat exchangers excel in thermal performance due to their large surface area and turbulent flow, resulting in improved heat transfer rates and compact design. You can achieve higher thermal efficiency and better energy savings by selecting plate heat exchangers for processes requiring close temperature approaches and frequent cleaning.

Space and Installation Requirements

Shell and tube heat exchangers require more space and a robust foundation due to their larger size and heavier weight, making them less suitable for compact installations. Plate heat exchangers offer a compact design with a smaller footprint, allowing for easier installation in tight spaces and simpler maintenance. Your choice impacts facility layout and installation costs, especially where space constraints are critical.

Maintenance and Cleaning Considerations

Shell and tube heat exchangers require more frequent maintenance due to potential tube fouling and scaling, with cleaning often involving mechanical or chemical methods that can be time-consuming and labor-intensive. Plate heat exchangers offer easier cleaning and inspection through their removable plates, which allow for quick access and straightforward replacement or cleaning without specialized tools. Both types demand regular monitoring, but plate heat exchangers generally provide lower downtime and simplified maintenance procedures compared to shell and tube designs.

Cost Analysis: Initial and Long-Term

Shell and tube heat exchangers typically have higher initial costs due to their robust construction and ability to handle high pressures and temperatures, making them suitable for heavy-duty industrial applications. Plate heat exchangers offer lower upfront costs and improved energy efficiency through enhanced heat transfer rates, leading to reduced operational expenses and easier maintenance over the long term. Long-term cost analysis favors plate exchangers in applications requiring frequent cleaning and flexible capacity, while shell and tube exchangers remain cost-effective for processes demanding durability and large-scale heat exchange.

Application Suitability and Industries

Shell and tube heat exchangers excel in high-pressure and high-temperature applications, commonly found in oil refineries, chemical plants, and power generation industries. Plate heat exchangers are ideal for sanitary and low to medium pressure processes, widely used in food and beverage, pharmaceuticals, and HVAC systems. Choosing the right heat exchanger depends on your specific application requirements, such as space constraints, maintenance needs, and thermal efficiency.

Choosing the Right Heat Exchanger for Your Needs

Selecting the right heat exchanger depends on factors such as thermal efficiency, space constraints, maintenance, and fluid compatibility. Shell and tube exchangers excel in handling high pressures and temperatures with robust construction, ideal for large-scale industrial applications. Plate heat exchangers offer superior heat transfer efficiency and compact design, making them suitable for low to medium pressure systems where space savings and ease of cleaning are priorities.

Shell and tube exchanger vs plate heat exchanger Infographic

libmatt.com

libmatt.com