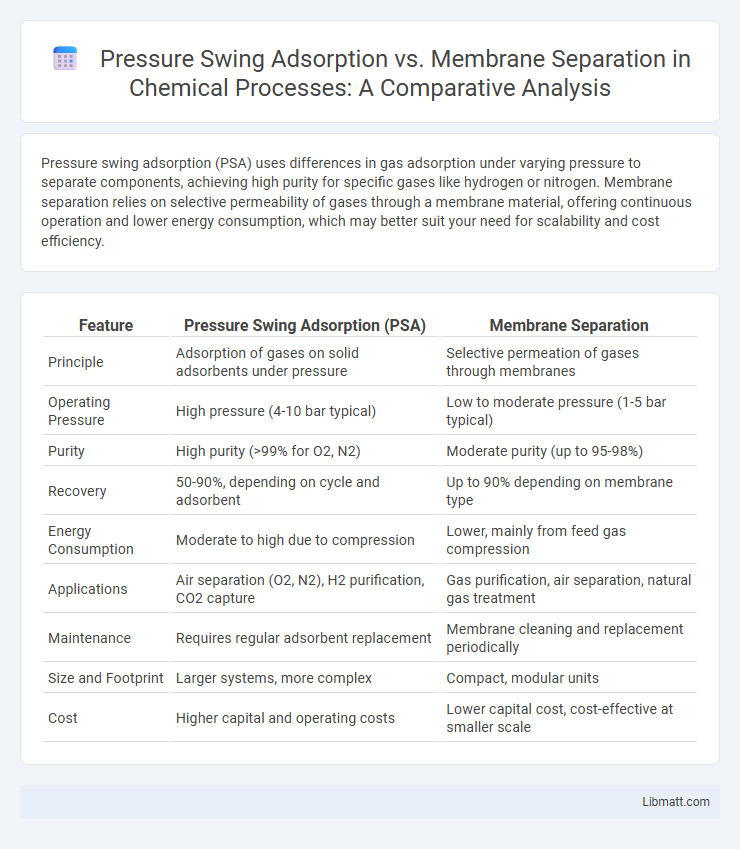

Pressure swing adsorption (PSA) uses differences in gas adsorption under varying pressure to separate components, achieving high purity for specific gases like hydrogen or nitrogen. Membrane separation relies on selective permeability of gases through a membrane material, offering continuous operation and lower energy consumption, which may better suit your need for scalability and cost efficiency.

Table of Comparison

| Feature | Pressure Swing Adsorption (PSA) | Membrane Separation |

|---|---|---|

| Principle | Adsorption of gases on solid adsorbents under pressure | Selective permeation of gases through membranes |

| Operating Pressure | High pressure (4-10 bar typical) | Low to moderate pressure (1-5 bar typical) |

| Purity | High purity (>99% for O2, N2) | Moderate purity (up to 95-98%) |

| Recovery | 50-90%, depending on cycle and adsorbent | Up to 90% depending on membrane type |

| Energy Consumption | Moderate to high due to compression | Lower, mainly from feed gas compression |

| Applications | Air separation (O2, N2), H2 purification, CO2 capture | Gas purification, air separation, natural gas treatment |

| Maintenance | Requires regular adsorbent replacement | Membrane cleaning and replacement periodically |

| Size and Footprint | Larger systems, more complex | Compact, modular units |

| Cost | Higher capital and operating costs | Lower capital cost, cost-effective at smaller scale |

Introduction to Gas Separation Technologies

Pressure swing adsorption (PSA) and membrane separation are advanced gas separation technologies widely used in industrial applications. PSA operates by selectively adsorbing specific gases onto porous materials at varying pressures, achieving high purity and recovery rates, while membrane separation relies on selective permeability of gases through polymeric or ceramic membranes, offering continuous operation with lower energy consumption. Your choice between these technologies depends on factors like gas composition, desired purity, and operational costs, ensuring optimal efficiency for processes such as air separation, hydrogen purification, or carbon dioxide capture.

Overview of Pressure Swing Adsorption (PSA)

Pressure Swing Adsorption (PSA) is a widely used gas separation technology that relies on adsorption at high pressure and desorption at low pressure to selectively separate gases based on their molecular properties. PSA systems use adsorbent materials such as zeolites or activated carbon to capture specific gas components like oxygen or nitrogen from air streams, enabling high-purity gas production. Your choice of PSA technology can optimize gas separation efficiency, energy consumption, and operational costs compared to membrane separation methods.

Fundamentals of Membrane Separation

Membrane separation relies on selective permeability of membranes to separate gases or liquids based on their molecular size, solubility, or diffusivity differences, providing efficient and energy-saving separation. Pressure swing adsorption (PSA) separates gases by adsorbing target components onto solid adsorbents at high pressure and desorbing them at low pressure, whereas membrane separation continuously filters molecules across a semi-permeable barrier. Your choice depends on factors such as feed composition, desired purity, and operational costs, with membranes often favored for compact, low-maintenance applications.

Core Principles: How PSA Works

Pressure Swing Adsorption (PSA) operates by selectively adsorbing gas species under high pressure on a porous adsorbent material, then desorbing them at lower pressure to achieve gas separation. The process cycles between pressurization and depressurization to separate components based on their molecular properties and affinity to the adsorbent. PSA is widely used for oxygen or nitrogen generation, offering high purity and efficient separation by exploiting pressure-dependent adsorption equilibria.

Core Principles: How Membrane Separation Works

Membrane separation operates by selectively allowing certain molecules to pass through a semi-permeable membrane based on size, solubility, or diffusivity differences, effectively separating gases or liquids without phase change. The membranes are typically polymeric or ceramic materials designed to provide high permeability and selectivity for target components. This process relies on pressure differentials to drive the permeation, resulting in energy-efficient separation with controllable purity and recovery rates compared to Pressure Swing Adsorption (PSA) technologies.

Key Advantages of Pressure Swing Adsorption

Pressure Swing Adsorption (PSA) offers high purity gas separation with efficient energy consumption by selectively adsorbing specific molecules under pressure changes. PSA systems provide scalability and flexibility for various gas compositions and flow rates, making them suitable for industrial applications like hydrogen purification and oxygen generation. Unlike membrane separation, PSA achieves deeper separation levels without requiring high-pressure feed gas, reducing overall operational costs.

Key Advantages of Membrane Separation

Membrane separation offers key advantages such as energy efficiency and operational simplicity compared to pressure swing adsorption (PSA). It provides continuous gas separation with minimal moving parts, reducing maintenance requirements and enhancing system reliability. Your choice of membrane technology can also deliver higher purity with compact footprint, making it ideal for space-constrained applications.

Comparative Efficiency: PSA vs Membrane

Pressure swing adsorption (PSA) offers high purity gas separation and is particularly efficient for large-scale oxygen or hydrogen production with purity levels often exceeding 99%. Membrane separation provides energy-efficient, continuous gas separation suitable for small to medium-scale applications, with lower purity output typically around 90-95%. Your choice depends on balancing PSA's superior purity and capacity against membrane systems' lower operational costs and simpler scalability.

Applications in Industry: Use Cases and Suitability

Pressure swing adsorption (PSA) is widely used in industries such as hydrogen purification, oxygen generation, and nitrogen production due to its high purity output and cost-effectiveness for large-scale gas separation. Membrane separation excels in natural gas processing, biogas upgrading, and carbon dioxide capture, offering energy-efficient operation and compact system design suitable for smaller-scale or continuous separation processes. You should consider PSA for applications requiring ultra-pure gases and membrane separation when space constraints and lower energy consumption are critical factors.

Choosing the Right Technology: Factors to Consider

Choosing the right technology between pressure swing adsorption (PSA) and membrane separation depends on factors such as gas purity requirements, production capacity, and energy efficiency. PSA offers high purity levels for gases like oxygen and hydrogen, making it suitable for industrial-scale applications, while membrane separation provides a more compact, energy-efficient solution ideal for smaller-scale operations or partial gas separation. Evaluating your specific process needs, operational costs, and maintenance demands will help determine the most effective method for your gas separation goals.

Pressure swing adsorption vs membrane separation Infographic

libmatt.com

libmatt.com