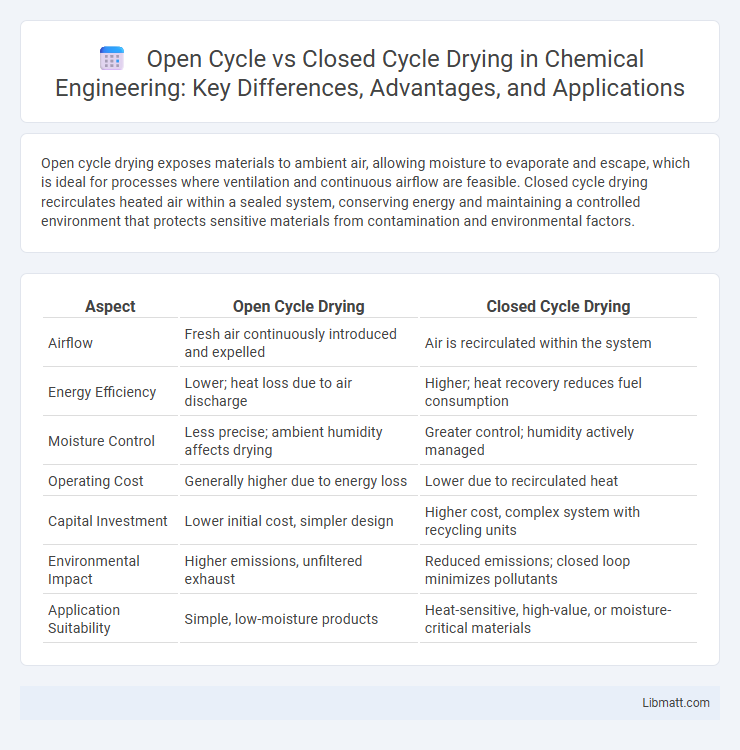

Open cycle drying exposes materials to ambient air, allowing moisture to evaporate and escape, which is ideal for processes where ventilation and continuous airflow are feasible. Closed cycle drying recirculates heated air within a sealed system, conserving energy and maintaining a controlled environment that protects sensitive materials from contamination and environmental factors.

Table of Comparison

| Aspect | Open Cycle Drying | Closed Cycle Drying |

|---|---|---|

| Airflow | Fresh air continuously introduced and expelled | Air is recirculated within the system |

| Energy Efficiency | Lower; heat loss due to air discharge | Higher; heat recovery reduces fuel consumption |

| Moisture Control | Less precise; ambient humidity affects drying | Greater control; humidity actively managed |

| Operating Cost | Generally higher due to energy loss | Lower due to recirculated heat |

| Capital Investment | Lower initial cost, simpler design | Higher cost, complex system with recycling units |

| Environmental Impact | Higher emissions, unfiltered exhaust | Reduced emissions; closed loop minimizes pollutants |

| Application Suitability | Simple, low-moisture products | Heat-sensitive, high-value, or moisture-critical materials |

Introduction to Drying Systems

Open cycle drying systems expose the material directly to hot air, allowing moisture to evaporate and be carried away with the exhaust air, which makes them suitable for applications where contamination control is less critical. Closed cycle drying systems recirculate the drying medium, typically air or gas, within a sealed loop, enhancing energy efficiency and preventing contamination by isolating the drying environment from external air. The choice between open and closed cycle drying depends on factors like the sensitivity of the product, energy consumption targets, and process control requirements.

Understanding Open Cycle Drying

Open cycle drying involves the direct exposure of moist air to the environment, where the wet air is continuously replaced with fresh air, making it energy-intensive due to heat loss. This method is commonly used in processes where humidity control is less critical or outdoor air is readily available, such as in grain drying. Your choice of open cycle drying should consider factors like energy costs and environmental conditions to optimize efficiency and product quality.

Overview of Closed Cycle Drying

Closed cycle drying recirculates drying air within the system, minimizing moisture release and heat loss, which improves energy efficiency. This method maintains a controlled drying environment by filtering and reheating the same air, making it ideal for sensitive materials requiring consistent temperature and humidity. Your operation benefits from reduced emissions and lower operational costs compared to open cycle drying systems.

Key Differences Between Open and Closed Cycle Drying

Open cycle drying involves direct exposure of the drying air to the material, allowing moisture to evaporate into the atmosphere, which can lead to energy loss and potential environmental pollution. Closed cycle drying recirculates the drying air within a sealed system, minimizing heat loss and preventing contamination, resulting in higher energy efficiency and better control over drying conditions. Key differences include the open system's reliance on ambient air versus the closed system's use of recycled air, affecting energy consumption, process control, and environmental impact.

Energy Efficiency Comparison

Open cycle drying systems typically exhibit lower energy efficiency due to continuous heat loss as moist air is exhausted to the atmosphere, resulting in higher fuel consumption. Closed cycle drying recirculates heated air, minimizing thermal energy waste and enabling better control over humidity and temperature, which significantly improves energy efficiency. Energy savings in closed cycle drying can reach up to 30-50% compared to open cycle systems, making it preferable for reducing operational costs and environmental impact.

Environmental Impact Assessment

Open cycle drying releases moisture and contaminants directly into the atmosphere, increasing emissions and potential air quality problems, while closed cycle drying captures and recirculates air, significantly reducing environmental pollutants and energy consumption. Closed cycle drying systems minimize water usage and chemical discharge by recycling process streams, leading to a smaller ecological footprint compared to open cycle methods. Life cycle assessments show that closed cycle drying improves sustainability by lowering greenhouse gas emissions and mitigating environmental degradation associated with drying operations.

Moisture Control and Product Quality

Open cycle drying exposes products to ambient air, which can lead to less precise moisture control and potential contamination, impacting product quality negatively. Closed cycle drying recirculates heated air in a sealed environment, allowing better control over humidity and temperature, ensuring consistent moisture removal and preserving the product's integrity. You can achieve superior product quality and extended shelf life through the enhanced moisture control of closed cycle drying systems.

Applications of Open Cycle Drying

Open cycle drying is commonly applied in industries where quick moisture removal is essential, such as agriculture for drying grains and in food processing to maintain product quality. Its use in wastewater treatment helps reduce sludge volume by evaporating moisture efficiently. You benefit from open cycle drying in scenarios requiring lower operational costs and simpler system design compared to closed cycle drying.

Applications of Closed Cycle Drying

Closed cycle drying is widely used in industries requiring precise humidity control and contamination prevention, such as pharmaceuticals, food processing, and electronics manufacturing. This method recycles the drying air, minimizing environmental emissions and improving energy efficiency, which makes it ideal for applications involving sensitive or hazardous materials. Your production processes can benefit from enhanced product quality and reduced operational costs through the consistent drying conditions provided by closed cycle systems.

Choosing the Right Drying Cycle for Your Needs

Selecting the appropriate drying cycle depends on the material sensitivity and energy efficiency requirements. Open cycle drying exposes the product to ambient air, making it suitable for heat-resistant materials but less energy-efficient. Closed cycle drying recirculates heated air, offering better humidity control and energy savings, ideal for sensitive or high-value products in your drying process.

Open cycle vs closed cycle drying Infographic

libmatt.com

libmatt.com