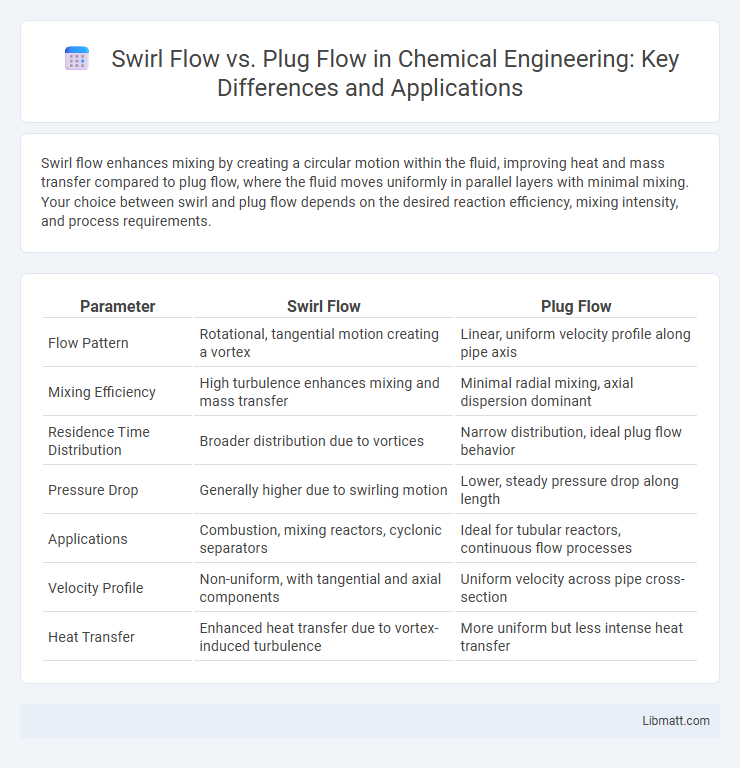

Swirl flow enhances mixing by creating a circular motion within the fluid, improving heat and mass transfer compared to plug flow, where the fluid moves uniformly in parallel layers with minimal mixing. Your choice between swirl and plug flow depends on the desired reaction efficiency, mixing intensity, and process requirements.

Table of Comparison

| Parameter | Swirl Flow | Plug Flow |

|---|---|---|

| Flow Pattern | Rotational, tangential motion creating a vortex | Linear, uniform velocity profile along pipe axis |

| Mixing Efficiency | High turbulence enhances mixing and mass transfer | Minimal radial mixing, axial dispersion dominant |

| Residence Time Distribution | Broader distribution due to vortices | Narrow distribution, ideal plug flow behavior |

| Pressure Drop | Generally higher due to swirling motion | Lower, steady pressure drop along length |

| Applications | Combustion, mixing reactors, cyclonic separators | Ideal for tubular reactors, continuous flow processes |

| Velocity Profile | Non-uniform, with tangential and axial components | Uniform velocity across pipe cross-section |

| Heat Transfer | Enhanced heat transfer due to vortex-induced turbulence | More uniform but less intense heat transfer |

Introduction to Flow Regimes

Swirl flow and plug flow represent distinct fluid flow regimes important in mixing and transport processes. Swirl flow is characterized by a rotational motion around the flow axis, enhancing radial mixing and increasing mass transfer rates. Plug flow exhibits uniform velocity across the flow cross-section with minimal axial dispersion, ideal for predictable reaction times in chemical reactors.

Defining Swirl Flow

Swirl flow is characterized by a rotational motion around the central axis, enhancing mixing and heat transfer within a fluid system. This tangential velocity component generates centrifugal forces, promoting radial dispersion of particles or heat. Unlike plug flow, which maintains uniform velocity profiles, swirl flow induces complex flow patterns that improve reactor performance and process efficiency.

Understanding Plug Flow

Plug flow refers to a fluid movement pattern where all particles travel at the same velocity, maintaining a uniform flow profile with minimal mixing along the flow direction. This ideal flow ensures that each fluid element experiences the same residence time, optimizing reaction efficiency in processes like chemical reactors or heat exchangers. Understanding plug flow helps you design systems with predictable performance and enhanced mass or heat transfer characteristics.

Key Characteristics of Swirl Flow

Swirl flow features a rotational motion around the axis of the pipe, creating a vortex that enhances mixing and heat transfer efficiency. Key characteristics include high turbulence intensity, radial velocity components, and centrifugal forces that promote particle suspension and prevent settling. You can exploit swirl flow in applications requiring improved mixing and reduced boundary layer thickness compared to plug flow's uniform velocity profile.

Key Attributes of Plug Flow

Plug flow is characterized by a uniform velocity profile across the cross-section of the flow, minimizing mixing in the axial direction and ensuring that all fluid particles move in parallel layers. This type of flow exhibits negligible radial and axial dispersion, leading to predictable residence times essential for processes like chemical reactors and heat exchangers. The predictable plug flow pattern maximizes reaction efficiency and performance by maintaining consistent concentration gradients throughout the system.

Major Differences Between Swirl and Plug Flow

Swirl flow features a rotational motion causing fluid particles to move in a helical path, enhancing mixing and heat transfer, whereas plug flow involves uniform velocity across the pipe cross-section with minimal radial mixing. The key difference lies in flow pattern: swirl flow creates tangential velocity components leading to turbulence, while plug flow maintains a laminar, parabolic profile with constant velocity. Your understanding of these distinctions informs the design of reactors, pipelines, and heat exchangers for optimized performance.

Applications of Swirl Flow in Industry

Swirl flow is widely applied in industries such as combustion engines, chemical reactors, and gas turbines where enhanced mixing and heat transfer are critical for efficiency and performance. Its ability to promote turbulent flow improves fuel-air mixing, reducing emissions and increasing combustion stability. Your processes can benefit from swirl flow by achieving better concentration uniformity and controlled reaction rates in industrial mixing applications.

Plug Flow Usage Across Sectors

Plug flow reactors are widely used in chemical processing industries such as pharmaceuticals, petrochemicals, and wastewater treatment due to their ability to maintain uniform residence time and consistent reaction conditions. This flow pattern enhances reaction efficiency and product quality in continuous manufacturing processes by minimizing back-mixing and channeling effects. In contrast to swirl flow reactors, plug flow systems are preferred when precise control over reaction kinetics and product distribution is critical.

Advantages and Limitations of Each Flow Type

Swirl flow enhances mixing and heat transfer efficiency by creating a rotational motion, which improves mass transfer and reduces boundary layer thickness, but it can cause pressure drop and increased energy consumption. Plug flow offers uniform velocity profile and predictable residence time, making it ideal for processes requiring consistent reaction conditions, yet it may suffer from limited mixing and potential channeling issues. Your choice depends on balancing improved mixing benefits of swirl flow against the simplicity and uniformity advantages of plug flow for your application.

Choosing the Right Flow Regime for Optimal Performance

Swirl flow enhances mixing and heat transfer by inducing centrifugal forces, making it ideal for applications requiring rapid blending or combustion efficiency. Plug flow ensures uniform velocity and minimal back-mixing, suitable for precise chemical reactions and consistent processing times. Choosing the right flow regime depends on your process goals, with swirl flow favoring enhanced turbulence and plug flow prioritizing predictability and control.

swirl flow vs plug flow Infographic

libmatt.com

libmatt.com