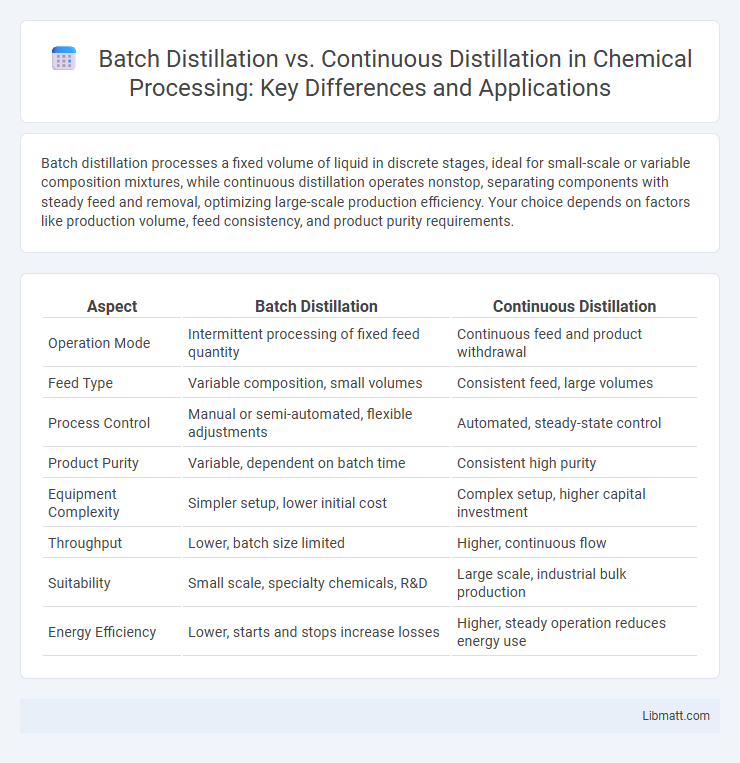

Batch distillation processes a fixed volume of liquid in discrete stages, ideal for small-scale or variable composition mixtures, while continuous distillation operates nonstop, separating components with steady feed and removal, optimizing large-scale production efficiency. Your choice depends on factors like production volume, feed consistency, and product purity requirements.

Table of Comparison

| Aspect | Batch Distillation | Continuous Distillation |

|---|---|---|

| Operation Mode | Intermittent processing of fixed feed quantity | Continuous feed and product withdrawal |

| Feed Type | Variable composition, small volumes | Consistent feed, large volumes |

| Process Control | Manual or semi-automated, flexible adjustments | Automated, steady-state control |

| Product Purity | Variable, dependent on batch time | Consistent high purity |

| Equipment Complexity | Simpler setup, lower initial cost | Complex setup, higher capital investment |

| Throughput | Lower, batch size limited | Higher, continuous flow |

| Suitability | Small scale, specialty chemicals, R&D | Large scale, industrial bulk production |

| Energy Efficiency | Lower, starts and stops increase losses | Higher, steady operation reduces energy use |

Introduction to Distillation Processes

Batch distillation involves processing a fixed volume of liquid in a single cycle, making it suitable for small-scale or variable-feed operations. Continuous distillation operates with a constant input and output stream, ideal for large-scale, steady-state separation of components. Both processes separate mixtures based on differences in boiling points but differ significantly in operation, efficiency, and application scale.

Overview of Batch Distillation

Batch distillation separates mixtures by heating a fixed volume of liquid in a single vessel, allowing volatile components to vaporize and condense sequentially. It excels in handling small quantities or varying feed compositions, offering flexibility for laboratory and specialty chemical production. The process is time-dependent and involves distinct phases: charge, heat-up, distillation, and cooling, making it suitable for products requiring high purity and customization.

Overview of Continuous Distillation

Continuous distillation operates by continuously feeding the liquid mixture into a distillation column while simultaneously withdrawing separated components, enabling uninterrupted separation of compounds based on boiling points. It is highly efficient for large-scale industrial processes, providing consistent product quality and higher throughput compared to batch distillation. The design often includes multiple trays or packing materials to enhance vapor-liquid contact, optimizing separation efficiency.

Key Differences Between Batch and Continuous Distillation

Batch distillation processes discrete amounts of liquid in specific time intervals, allowing for flexible operation and easy adjustment of product composition, whereas continuous distillation operates constantly, handling high volumes with steady-state conditions ideal for large-scale production. Batch distillation suits small-scale or variable feed compositions, while continuous distillation excels in efficiency and throughput for consistent feedstocks. Key differences include operation mode, scalability, product consistency, and equipment complexity, with continuous systems requiring more complex control but delivering greater productivity.

Equipment and Setup Requirements

Batch distillation requires simpler equipment, typically a single still pot and condenser, making it suitable for small-scale operations and flexible production runs. Continuous distillation involves more complex setups with multiple columns, trays, and reboilers designed for high-capacity, uninterrupted processing. Your choice between batch and continuous distillation depends on the scale, product consistency, and investment in infrastructure.

Operational Flexibility and Scalability

Batch distillation offers high operational flexibility by allowing you to process varying feed compositions and batch sizes easily, making it ideal for small-scale or specialty chemical production. Continuous distillation excels in scalability, providing consistent large-volume output with steady-state operation, best suited for industries requiring constant product quality and high throughput. Your choice depends on whether flexibility in operations or scalable, continuous production better aligns with your process needs.

Energy Efficiency Comparison

Batch distillation typically consumes more energy per unit of product due to repeated heating and cooling cycles, making it less energy-efficient for large-scale production. Continuous distillation maintains steady-state operation, optimizing heat integration and reducing energy consumption by minimizing temperature fluctuations. Your choice between the two should consider throughput requirements, with continuous distillation offering higher energy efficiency in high-volume industrial applications.

Product Purity and Yield Considerations

Batch distillation allows for flexible operation and is ideal for small-scale production, often resulting in varied product purity due to fluctuating composition throughout the run. Continuous distillation maintains consistent feed and steady operating conditions, achieving higher and more uniform product purity and yield for large-scale operations. The choice depends on production scale and purity requirements, with continuous distillation favored for maximizing yield and optimizing energy efficiency.

Typical Industrial Applications

Batch distillation is commonly utilized in industries requiring flexibility and small-to-medium production volumes, such as pharmaceutical manufacturing, specialty chemicals, and flavor and fragrance production. Continuous distillation dominates large-scale operations like petroleum refining, petrochemical processing, and large chemical plants where consistent product quality and high throughput are essential. Industrial sectors often select batch distillation for customizable separations and continuous distillation for high-efficiency, steady-state separation processes.

Choosing the Right Distillation Method

Selecting the appropriate distillation method depends on production scale, feedstock variability, and purity requirements. Batch distillation suits small-scale operations with frequent product changes and complex mixtures, offering flexibility and precise control. Continuous distillation excels in large-scale, consistent feed processing, delivering higher efficiency and steady output for uniform separation tasks.

batch distillation vs continuous distillation Infographic

libmatt.com

libmatt.com