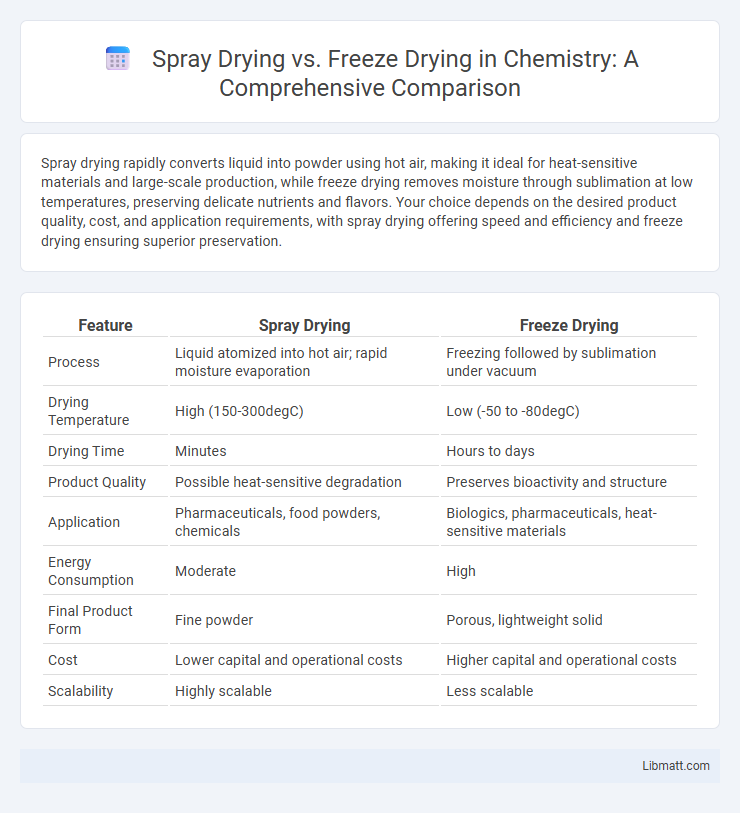

Spray drying rapidly converts liquid into powder using hot air, making it ideal for heat-sensitive materials and large-scale production, while freeze drying removes moisture through sublimation at low temperatures, preserving delicate nutrients and flavors. Your choice depends on the desired product quality, cost, and application requirements, with spray drying offering speed and efficiency and freeze drying ensuring superior preservation.

Table of Comparison

| Feature | Spray Drying | Freeze Drying |

|---|---|---|

| Process | Liquid atomized into hot air; rapid moisture evaporation | Freezing followed by sublimation under vacuum |

| Drying Temperature | High (150-300degC) | Low (-50 to -80degC) |

| Drying Time | Minutes | Hours to days |

| Product Quality | Possible heat-sensitive degradation | Preserves bioactivity and structure |

| Application | Pharmaceuticals, food powders, chemicals | Biologics, pharmaceuticals, heat-sensitive materials |

| Energy Consumption | Moderate | High |

| Final Product Form | Fine powder | Porous, lightweight solid |

| Cost | Lower capital and operational costs | Higher capital and operational costs |

| Scalability | Highly scalable | Less scalable |

Introduction to Drying Techniques

Spray drying and freeze drying are advanced dehydration techniques widely used in food, pharmaceutical, and chemical industries to preserve sensitive materials. Spray drying rapidly transforms liquid solutions into powder by atomizing them into a hot drying chamber, effectively retaining flavor and nutrient content. Freeze drying, or lyophilization, removes moisture through sublimation at low temperatures, preserving the structural integrity and bioactivity of heat-sensitive products, making it ideal for extending shelf life.

What is Spray Drying?

Spray drying is a rapid drying technique that transforms liquid feed into a fine, dry powder by atomizing the liquid into hot air. This process preserves heat-sensitive materials by minimizing drying time and is widely used in the food, pharmaceutical, and chemical industries. Spray drying produces powders with controlled particle size and moisture content, enhancing product stability and shelf life.

What is Freeze Drying?

Freeze drying, also known as lyophilization, is a dehydration process that removes moisture from a product by freezing it and then reducing the surrounding pressure to allow the frozen water to sublimate directly from solid to gas. This method preserves the structural integrity, nutritional content, and bioactive compounds of sensitive materials, making it ideal for pharmaceuticals, food products, and biological samples. Freeze drying operates at low temperatures, preventing thermal degradation and ensuring longer shelf life compared to other drying techniques like spray drying.

Key Differences Between Spray Drying and Freeze Drying

Spray drying involves rapidly drying liquid feed into powder by spraying it into a hot chamber, ensuring quick moisture removal and cost-effective production, whereas freeze drying removes moisture through sublimation under low temperature and vacuum, preserving heat-sensitive compounds but requiring longer processing time. Spray drying is ideal for heat-stable materials and generates powders with lower porosity and density, while freeze drying maintains structural integrity and bioactivity of delicate substances, producing lightweight, highly porous powders. Key differences include processing temperature, drying time, product quality, and energy consumption, influencing their application in pharmaceuticals, food, and biotechnology industries.

Efficiency and Processing Time Comparison

Spray drying offers faster processing times, typically completing in minutes due to rapid solvent evaporation, making it highly efficient for large-scale production. Freeze drying requires longer cycles, often ranging from several hours to days, due to the sublimation process that preserves product structure but reduces throughput. Efficiency in spray drying is enhanced by continuous operation, whereas freeze drying's batch process limits speed but excels in maintaining product stability.

Impact on Product Quality

Spray drying preserves product quality by rapidly removing moisture through hot air, which maintains flavor and aroma but may cause heat-sensitive nutrient loss. Freeze drying offers superior retention of nutritional value, texture, and color by sublimating ice under low temperature and pressure, making it ideal for delicate products. Your choice between spray drying and freeze drying directly influences the final product's stability, shelf life, and sensory attributes.

Cost Factors and Commercial Considerations

Spray drying generally incurs lower operational costs due to faster drying cycles and continuous processing, making it ideal for large-scale production with cost efficiency. Freeze drying demands higher investment in equipment and energy, translating to greater upfront and maintenance expenses but offers superior preservation of heat-sensitive materials, influencing your product pricing strategy. Commercial considerations also include product quality requirements and shelf-life expectations, where spray drying suits bulk commodity products and freeze drying targets premium, niche markets with higher profit margins.

Applications Across Industries

Spray drying is commonly used in the food, pharmaceutical, and chemical industries for producing powdered products like milk powder, instant coffee, and pharmaceuticals due to its rapid processing and scalability. Freeze drying excels in preserving sensitive materials, such as biological samples, vaccines, and high-value nutrients, making it ideal for biotechnology and specialty food sectors. Your choice between spray drying and freeze drying depends on the desired product stability, cost considerations, and industry-specific application requirements.

Advantages and Disadvantages of Each Method

Spray drying offers rapid moisture removal and is cost-effective, making it ideal for heat-sensitive materials, but it can cause thermal degradation and lower nutrient retention. Freeze drying preserves product structure and nutritional content exceptionally well, but it is more time-consuming and expensive due to the need for low-temperature and vacuum conditions. Your choice depends on whether you prioritize speed and cost or maximum quality and preservation.

How to Choose the Best Drying Method

Choosing the best drying method depends on the product's sensitivity, desired shelf life, and cost constraints. Spray drying is efficient and economical for heat-stable substances, producing fine powders ideal for large-scale food or pharmaceutical production. Freeze drying preserves heat-sensitive compounds and bioactivity, extending shelf life at a higher operational cost suited for premium or delicate products.

Spray drying vs freeze drying Infographic

libmatt.com

libmatt.com