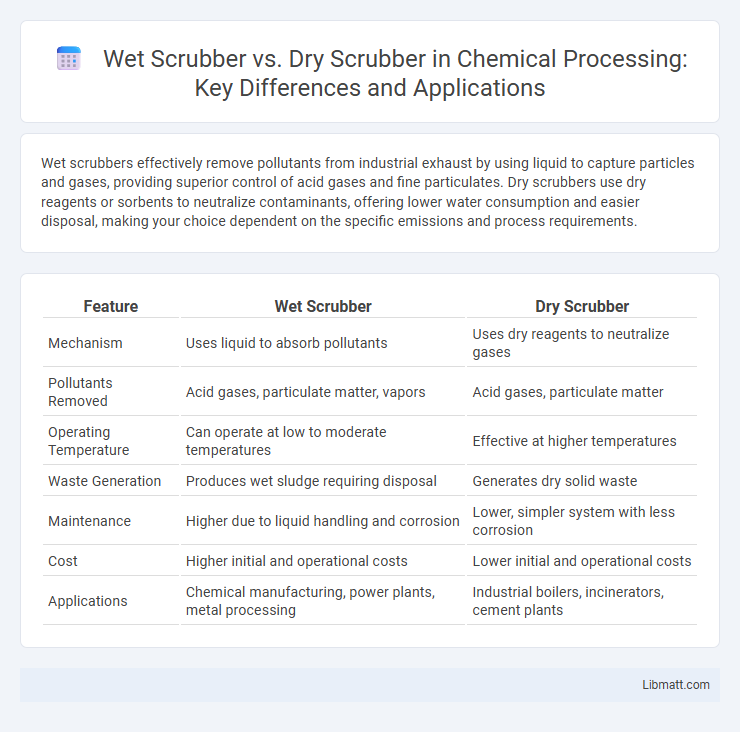

Wet scrubbers effectively remove pollutants from industrial exhaust by using liquid to capture particles and gases, providing superior control of acid gases and fine particulates. Dry scrubbers use dry reagents or sorbents to neutralize contaminants, offering lower water consumption and easier disposal, making your choice dependent on the specific emissions and process requirements.

Table of Comparison

| Feature | Wet Scrubber | Dry Scrubber |

|---|---|---|

| Mechanism | Uses liquid to absorb pollutants | Uses dry reagents to neutralize gases |

| Pollutants Removed | Acid gases, particulate matter, vapors | Acid gases, particulate matter |

| Operating Temperature | Can operate at low to moderate temperatures | Effective at higher temperatures |

| Waste Generation | Produces wet sludge requiring disposal | Generates dry solid waste |

| Maintenance | Higher due to liquid handling and corrosion | Lower, simpler system with less corrosion |

| Cost | Higher initial and operational costs | Lower initial and operational costs |

| Applications | Chemical manufacturing, power plants, metal processing | Industrial boilers, incinerators, cement plants |

Introduction to Wet and Dry Scrubbers

Wet scrubbers use a liquid solution to capture pollutants from industrial exhaust gases, effectively removing dust, acids, and volatile organic compounds through absorption and neutralization. Dry scrubbers rely on dry reagents or sorbents to react chemically with harmful gases, often preferred for handling alkaline or particulate emissions without producing wastewater. Choosing between wet and dry scrubbers depends on your facility's specific pollutant type, environmental regulations, and operational considerations.

How Wet Scrubbers Work

Wet scrubbers remove pollutants by passing contaminated gas through a liquid, typically water, which captures and dissolves particulate matter and gases. This process effectively cleans your industrial emissions by utilizing droplets or sprays that absorb or chemically react with contaminants. The continuous liquid flow also cools the gas stream, enhancing pollutant removal efficiency.

How Dry Scrubbers Work

Dry scrubbers remove pollutants by injecting a dry sorbent, such as hydrated lime or sodium bicarbonate, into the flue gas stream, where it reacts chemically with acidic gases like sulfur dioxide (SO2) and hydrogen chloride (HCl). The resulting solid reaction products are captured by downstream particulate control devices such as fabric filters or electrostatic precipitators, effectively reducing emissions. This process operates without using liquid, minimizing wastewater production and simplifying maintenance compared to wet scrubbers.

Key Differences Between Wet and Dry Scrubbers

Wet scrubbers use liquid, typically water, to remove pollutants from industrial exhaust gases, capturing particulates and soluble gases through absorption; dry scrubbers employ dry reagents or sorbents to neutralize acidic gases and capture particulates without introducing moisture. Wet scrubbers offer high removal efficiency for fine particles and acid gases but require wastewater treatment and have higher operational costs, whereas dry scrubbers are easier to maintain, produce solid waste instead of wastewater, and are suitable for smaller gas volumes. Selection depends on factors like gas composition, moisture content, space availability, and regulatory requirements for emissions control.

Applications of Wet Scrubbers

Wet scrubbers are widely used in industrial applications requiring efficient removal of acid gases, particulates, and volatile organic compounds (VOCs) from flue gases in power plants, chemical manufacturing, and metal processing facilities. They excel in processes involving high-temperature gases or sticky particles, such as waste incineration and cement production, where moisture helps capture contaminants. Wet scrubbers also play a critical role in controlling air pollution in industries with corrosive or reactive pollutants, providing versatile and effective gas cleaning solutions.

Applications of Dry Scrubbers

Dry scrubbers are ideal for industries requiring particulate removal from flue gases without using water, such as cement manufacturing, power plants, and chemical processing. They effectively capture acidic gases like sulfur dioxide and hydrogen chloride through the injection of alkaline sorbents, minimizing corrosion and wastewater issues. Your facility benefits from dry scrubbers by reducing operational costs and simplifying maintenance in dry, abrasive, or cold environments.

Efficiency Comparison: Wet vs Dry Scrubbers

Wet scrubbers typically achieve higher efficiency in removing fine particulates and gaseous pollutants due to their ability to capture contaminants through liquid absorption and chemical reactions. Dry scrubbers, while generally less efficient in particulate removal, are more effective for handling high-temperature gases and solid waste generation is minimized, making them suitable for specific industrial applications. Your choice between wet and dry scrubbers depends on the pollutant type, operational conditions, and desired removal efficiency.

Environmental Impact of Wet and Dry Scrubbers

Wet scrubbers effectively remove acidic gases and particulate matter by using a liquid solution, significantly reducing air pollution and minimizing toxic emissions. Dry scrubbers, while generating less wastewater and requiring lower maintenance, may produce solid waste that needs careful disposal to prevent soil contamination. Both technologies contribute to cleaner industrial emissions but differ in waste management and environmental footprint depending on the specific pollutants and operational conditions.

Cost Analysis: Wet Scrubber vs Dry Scrubber

Wet scrubbers generally have higher initial installation costs compared to dry scrubbers due to their complex water spray systems and wastewater treatment requirements. However, dry scrubbers often incur higher maintenance expenses over time because of periodic replacement of sorbent materials and disposal of solid waste byproducts. Your choice should consider both upfront capital investment and ongoing operational costs to determine the most cost-effective solution for your specific air pollution control needs.

Choosing the Right Scrubber for Your Facility

Selecting the right scrubber involves evaluating your facility's specific pollutant types and removal efficiency requirements; wet scrubbers excel in removing soluble gases and fine particulates, while dry scrubbers are effective against acidic gases and dust with lower water usage. Consider operational costs, maintenance needs, and environmental regulations to determine which system aligns best with your emission control goals. Integrating data on pollutant composition and flow rates ensures optimal performance and compliance, making the choice between wet and dry scrubbers critical for sustainable facility operation.

Wet scrubber vs dry scrubber Infographic

libmatt.com

libmatt.com