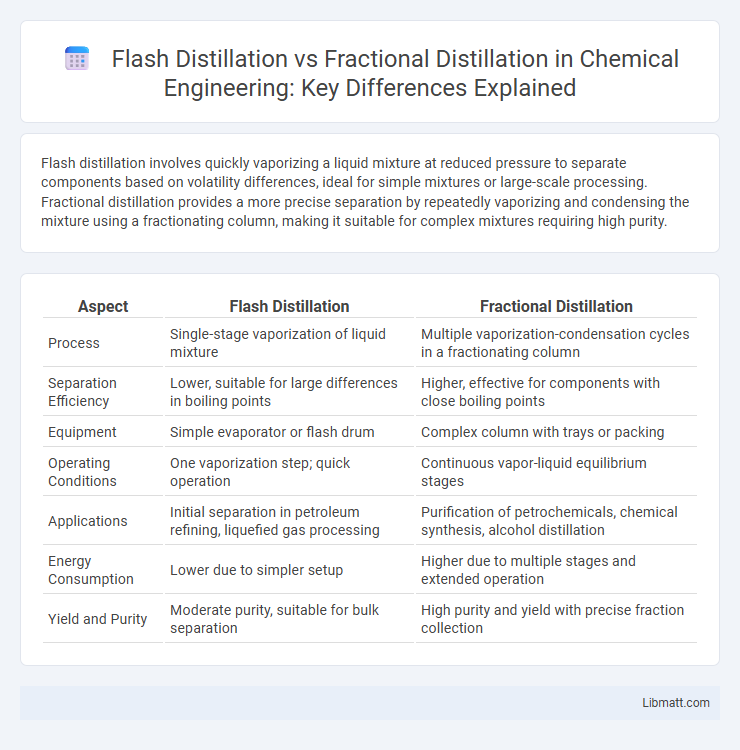

Flash distillation involves quickly vaporizing a liquid mixture at reduced pressure to separate components based on volatility differences, ideal for simple mixtures or large-scale processing. Fractional distillation provides a more precise separation by repeatedly vaporizing and condensing the mixture using a fractionating column, making it suitable for complex mixtures requiring high purity.

Table of Comparison

| Aspect | Flash Distillation | Fractional Distillation |

|---|---|---|

| Process | Single-stage vaporization of liquid mixture | Multiple vaporization-condensation cycles in a fractionating column |

| Separation Efficiency | Lower, suitable for large differences in boiling points | Higher, effective for components with close boiling points |

| Equipment | Simple evaporator or flash drum | Complex column with trays or packing |

| Operating Conditions | One vaporization step; quick operation | Continuous vapor-liquid equilibrium stages |

| Applications | Initial separation in petroleum refining, liquefied gas processing | Purification of petrochemicals, chemical synthesis, alcohol distillation |

| Energy Consumption | Lower due to simpler setup | Higher due to multiple stages and extended operation |

| Yield and Purity | Moderate purity, suitable for bulk separation | High purity and yield with precise fraction collection |

Introduction to Distillation Methods

Flash distillation rapidly separates components by heating a liquid mixture to vaporize the more volatile parts, allowing immediate vapor-liquid equilibrium, which is ideal for simple binary mixtures or when a quick separation is needed. Fractional distillation employs a fractionating column to create multiple vaporization-condensation cycles, achieving more precise separation of components with close boiling points, commonly used in petroleum refining and chemical manufacturing. Your choice between these methods depends on the mixture complexity, separation requirement, and operational efficiency.

What Is Flash Distillation?

Flash distillation is a separation process where a liquid mixture is rapidly heated to vaporize a portion of the liquid, immediately separating the components based on their volatility. This method operates under a single stage of equilibrium, making it ideal for quickly separating mixtures with large differences in boiling points. Flash distillation is commonly used in industries such as petrochemical refining to efficiently separate volatile compounds without multiple distillation steps.

Understanding Fractional Distillation

Fractional distillation separates complex mixtures by exploiting different boiling points using a fractionating column, which provides multiple vaporization-condensation cycles to enhance purity. Flash distillation rapidly vaporizes a liquid mixture at reduced pressure, offering a simpler but less precise separation compared to fractional distillation. Your ability to choose the right method depends on the desired separation efficiency and the nature of the components involved.

Key Principles Behind Each Process

Flash distillation operates on the principle of rapidly vaporizing a liquid mixture by reducing pressure or increasing temperature, causing a portion to vaporize instantly based on volatility differences. Fractional distillation relies on repeated vaporization-condensation cycles within a fractionating column, enabling more precise separation of components with close boiling points through differential condensation. Your choice depends on the desired purity and efficiency, with flash distillation suitable for quick separations and fractional distillation ideal for detailed fractionation.

Equipment Used in Flash vs Fractional Distillation

Flash distillation uses simpler equipment, typically involving a single-stage vapor-liquid separator or a flash drum to rapidly vaporize the liquid mixture at reduced pressure. Fractional distillation requires more complex apparatus, including a distillation column packed with trays or packing material to facilitate multiple vapor-liquid equilibrium stages and enable separation of components with close boiling points. The design and complexity of fractional distillation equipment result in higher separation efficiency compared to the straightforward setup of flash distillation.

Applications in Industry

Flash distillation is widely used in the petrochemical industry for rapid separation of light hydrocarbons and in wastewater treatment to quickly remove volatile contaminants. Fractional distillation is essential in petroleum refining to separate crude oil into valuable fractions like gasoline, diesel, and kerosene with high purity. Both technologies optimize separation processes based on volatility differences, but fractional distillation offers greater precision for complex mixtures requiring multiple component isolation.

Advantages of Flash Distillation

Flash distillation offers rapid separation of volatile components by quickly reducing pressure and vaporizing part of the liquid mixture, resulting in lower energy consumption compared to fractional distillation. It requires simpler equipment with fewer stages, making it cost-effective and easier to operate for mixtures with large differences in boiling points. Flash distillation is also ideal for continuous processing and handling heat-sensitive materials due to its shorter residence time.

Benefits of Fractional Distillation

Fractional distillation offers precise separation of components with close boiling points by utilizing a fractionating column that provides multiple theoretical plates, enhancing purity and yield. It is highly effective in industries such as petroleum refining and chemical manufacturing where complex mixtures require efficient separation. This method reduces energy consumption and operational costs by minimizing the need for repeated distillation cycles compared to flash distillation.

Limitations and Challenges

Flash distillation faces limitations such as lower separation efficiency and difficulty handling mixtures with close boiling points, which can result in incomplete separation. Fractional distillation, while offering better separation for complex mixtures, involves higher energy consumption and increased equipment costs due to the need for multiple theoretical plates or trays. Both methods struggle with temperature-sensitive compounds that may degrade under prolonged heating or excessive thermal exposure.

Choosing the Right Distillation Method

Selecting the appropriate distillation method depends on the feed mixture's boiling point differences and purity requirements. Flash distillation suits mixtures with widely spaced boiling points and lower purity needs, offering faster separation by vaporizing a portion of the liquid instantly under reduced pressure. Fractional distillation is ideal for separating components with close boiling points, employing a fractionating column to achieve higher purity through repeated vaporization-condensation cycles.

Flash distillation vs fractional distillation Infographic

libmatt.com

libmatt.com