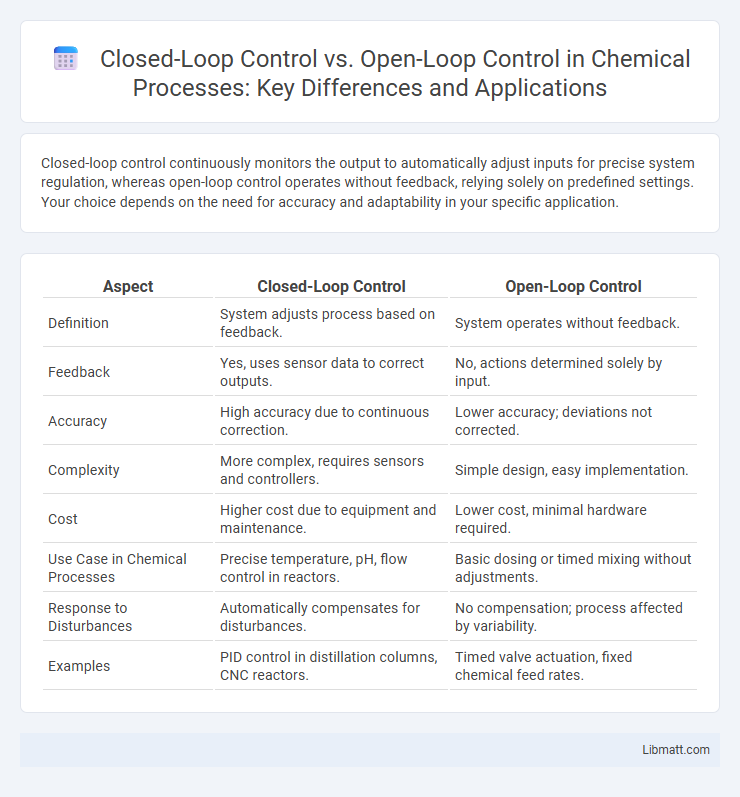

Closed-loop control continuously monitors the output to automatically adjust inputs for precise system regulation, whereas open-loop control operates without feedback, relying solely on predefined settings. Your choice depends on the need for accuracy and adaptability in your specific application.

Table of Comparison

| Aspect | Closed-Loop Control | Open-Loop Control |

|---|---|---|

| Definition | System adjusts process based on feedback. | System operates without feedback. |

| Feedback | Yes, uses sensor data to correct outputs. | No, actions determined solely by input. |

| Accuracy | High accuracy due to continuous correction. | Lower accuracy; deviations not corrected. |

| Complexity | More complex, requires sensors and controllers. | Simple design, easy implementation. |

| Cost | Higher cost due to equipment and maintenance. | Lower cost, minimal hardware required. |

| Use Case in Chemical Processes | Precise temperature, pH, flow control in reactors. | Basic dosing or timed mixing without adjustments. |

| Response to Disturbances | Automatically compensates for disturbances. | No compensation; process affected by variability. |

| Examples | PID control in distillation columns, CNC reactors. | Timed valve actuation, fixed chemical feed rates. |

Introduction to Control Systems

Closed-loop control systems utilize feedback to continuously monitor output and adjust inputs, ensuring accuracy and stability in dynamic environments. Open-loop control systems operate without feedback, relying solely on pre-set inputs, which can lead to errors when disturbances affect system performance. Control system design prioritizes closed-loop architectures for applications demanding precision and adaptability.

Defining Open-Loop Control

Open-loop control operates by executing a predetermined sequence of commands without using feedback to adjust its actions. This type of system relies solely on initial input and predetermined settings, making it simpler but less adaptable to disturbances or changes in the environment. Your process may benefit from open-loop control when precision feedback is unavailable or unnecessary.

Defining Closed-Loop Control

Closed-loop control systems continuously monitor output through feedback to automatically adjust input, ensuring the desired system performance despite disturbances or changes in conditions. These systems use sensors to measure actual output, compare it to the reference input, and apply corrections based on the error signal, enhancing accuracy and stability. Examples include thermostats, speed control in motors, and automated flight control systems.

Key Differences Between Open-Loop and Closed-Loop Control

Open-loop control operates without feedback, relying solely on predefined input commands to control a system, resulting in less accuracy and adaptability. Closed-loop control continuously monitors output through feedback to adjust inputs, enabling higher precision and the ability to correct disturbances. The key differences lie in feedback utilization, system adaptability, and error correction capability, with closed-loop systems providing dynamic control and open-loop systems maintaining simplicity and lower cost.

Advantages of Open-Loop Control Systems

Open-loop control systems offer simplicity and cost-effectiveness due to their straightforward design without feedback components. They provide fast response times since the control action is predetermined and not dependent on system output measurement. Open-loop systems are suitable for applications with stable, predictable processes where precision and error correction are less critical.

Advantages of Closed-Loop Control Systems

Closed-loop control systems offer significant advantages such as enhanced accuracy and stability by continuously monitoring output and adjusting inputs based on feedback, reducing errors caused by external disturbances or system fluctuations. They improve system performance through real-time correction, ensuring consistent and reliable operation in complex environments. This feedback mechanism also allows for adaptive control, making closed-loop systems ideal for dynamic and unpredictable processes compared to the fixed response of open-loop systems.

Limitations of Open-Loop Control

Open-loop control systems operate without feedback, making them unable to automatically correct errors or adapt to external disturbances, which limits their precision and reliability. These systems are highly susceptible to variations in system parameters and environmental conditions, often resulting in performance degradation and increased error rates. The lack of real-time monitoring prevents open-loop control from maintaining consistent output, especially in dynamic or unpredictable processes.

Limitations of Closed-Loop Control

Closed-loop control systems face limitations such as increased complexity and higher costs due to the integration of sensors and feedback mechanisms. They may experience stability issues and slower response times compared to open-loop control, especially in systems with significant delays or noise in feedback signals. Your choice of control system should consider these factors to ensure optimal performance and reliability.

Applications: When to Use Open vs Closed-Loop Control

Open-loop control is ideal for simple, predictable systems where feedback is unnecessary, such as basic household appliances or timing-based processes. Closed-loop control suits complex and dynamic environments requiring accuracy and adaptability, like robotic arms, temperature regulation systems, and autonomous vehicles. Choosing between open and closed-loop control depends on factors like precision needs, system variability, and real-time response requirements.

Conclusion: Selecting the Right Control Strategy

Choosing the ideal control strategy depends on your system's need for accuracy and adaptability; closed-loop control offers real-time feedback and correction, enhancing precision in dynamic environments. Open-loop control suits simpler, predictable processes where cost and simplicity are priorities, as it operates without feedback. Assess system complexity, desired performance, and environmental variability to determine whether closed-loop or open-loop control aligns best with your operational goals.

closed-loop control vs open-loop control Infographic

libmatt.com

libmatt.com