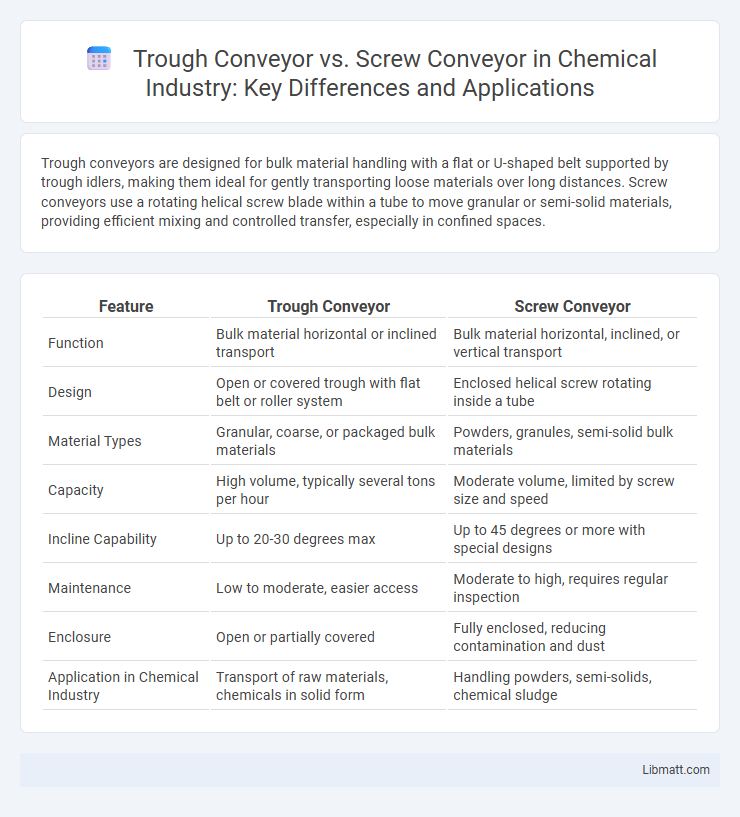

Trough conveyors are designed for bulk material handling with a flat or U-shaped belt supported by trough idlers, making them ideal for gently transporting loose materials over long distances. Screw conveyors use a rotating helical screw blade within a tube to move granular or semi-solid materials, providing efficient mixing and controlled transfer, especially in confined spaces.

Table of Comparison

| Feature | Trough Conveyor | Screw Conveyor |

|---|---|---|

| Function | Bulk material horizontal or inclined transport | Bulk material horizontal, inclined, or vertical transport |

| Design | Open or covered trough with flat belt or roller system | Enclosed helical screw rotating inside a tube |

| Material Types | Granular, coarse, or packaged bulk materials | Powders, granules, semi-solid bulk materials |

| Capacity | High volume, typically several tons per hour | Moderate volume, limited by screw size and speed |

| Incline Capability | Up to 20-30 degrees max | Up to 45 degrees or more with special designs |

| Maintenance | Low to moderate, easier access | Moderate to high, requires regular inspection |

| Enclosure | Open or partially covered | Fully enclosed, reducing contamination and dust |

| Application in Chemical Industry | Transport of raw materials, chemicals in solid form | Handling powders, semi-solids, chemical sludge |

Introduction to Trough and Screw Conveyors

Trough conveyors utilize an open trough-shaped belt system designed for transporting bulk materials with minimal spillage, making them ideal for handling granular or irregularly shaped items. Screw conveyors employ a rotating helical screw blade housed in a tube or trough to move materials efficiently, particularly suited for viscous or semi-solid substances. Both conveyors are widely used in industries such as agriculture, mining, and manufacturing, with selection depending on material properties and conveying requirements.

How Trough Conveyors Work

Trough conveyors operate by moving bulk materials along a U-shaped frame using a continuous belt that runs over pulleys, allowing efficient transport of large volumes with minimal spillage. The belt's tension and trough angle ensure stable material flow, making it ideal for handling coal, grain, or aggregates. Unlike screw conveyors that use rotating helical blades to push materials, trough conveyors rely on friction between the belt and material, enhancing versatility for various industries.

How Screw Conveyors Operate

Screw conveyors operate by using a rotating helical screw blade, called a flighting, inside a trough or tube to move bulk materials efficiently along a fixed path. The rotation of the screw causes the material to be pushed forward through the conveyor system, enabling controlled and continuous transport of powders, granules, or semi-solid substances. Your choice between trough and screw conveyors should consider the specific material characteristics and operational requirements for optimal performance.

Key Differences Between Trough and Screw Conveyors

Trough conveyors feature an open-top design with a belt moving material along a U-shaped trough, ideal for handling larger, irregularly shaped items with minimal spillage. Screw conveyors use a rotating helical screw blade inside a tube or trough to move granular or semi-solid materials efficiently in confined spaces. Your choice depends on material type, space constraints, and the need for enclosed versus open transport during bulk handling operations.

Material Handling Capabilities

Trough conveyors excel in transporting bulk materials like grains, coal, and aggregates over long distances with high capacity and minimal material degradation. Screw conveyors are ideal for handling semi-solid, granular, or viscous materials in confined spaces, offering precise control over material flow and preventing spillage. Your choice depends on the specific material characteristics and the required transport efficiency within your operational setup.

Installation and Maintenance Requirements

Trough conveyors require straightforward installation with minimal alignment adjustments, making them easier to set up in various industrial settings, while screw conveyors demand more precise installation due to their rotating helical screw component. Maintenance for trough conveyors typically involves routine belt inspections and occasional track cleaning, whereas screw conveyors need regular monitoring of the screw shaft, bearings, and seals to prevent wear and ensure optimal performance. You should consider the operational environment and access for maintenance when selecting between the two, as screw conveyors often require more frequent servicing due to mechanical complexity.

Efficiency and Energy Consumption Comparison

Trough conveyors offer higher energy efficiency by using a simpler mechanism that reduces motor load, leading to lower operational costs compared to screw conveyors. Screw conveyors consume more energy due to their continuous rotational motion and mechanical friction, especially when handling abrasive or dense materials. Your choice of conveyor should balance the required throughput with energy consumption to optimize overall system efficiency.

Cost Analysis: Trough vs Screw Conveyors

Trough conveyors typically have lower initial costs due to simpler design and ease of installation, making them suitable for bulk materials with minimal maintenance requirements. Screw conveyors generally incur higher upfront expenses because of complex components and tighter tolerances, but they offer efficient handling of abrasive or sticky materials, potentially reducing long-term operational costs. Evaluating cost-effectiveness involves considering both the material characteristics and maintenance frequency to determine the best return on investment between trough and screw conveyor systems.

Typical Applications for Each Conveyor Type

Trough conveyors are commonly used in bulk material handling industries such as agriculture, mining, and food processing for transporting dry, free-flowing materials like grains, coal, and fertilizers. Screw conveyors excel in applications requiring precise control of material flow, including mixing, metering, and conveying viscous or semi-solid materials like cement, sludge, and powders in wastewater treatment plants, chemical, and food industries. The choice between trough and screw conveyors depends largely on the material characteristics and the need for controlled or continuous transportation.

Choosing the Right Conveyor for Your Needs

Selecting between a trough conveyor and a screw conveyor depends on your material type and handling requirements. Trough conveyors excel in transporting bulk materials gently over long distances with minimal spillage, while screw conveyors are ideal for moving granular or powdery substances within confined spaces. Understanding your operational environment and material characteristics ensures you choose the conveyor that maximizes efficiency and reduces maintenance costs.

trough conveyor vs screw conveyor Infographic

libmatt.com

libmatt.com