Dropwise condensation occurs when vapor condenses into discrete droplets on a surface, enhancing heat transfer efficiency due to minimal thermal resistance, whereas filmwise condensation forms a continuous liquid film that impedes heat transfer by creating a thermal barrier. Understanding the difference helps you optimize heat exchanger design and improve system performance by promoting dropwise condensation.

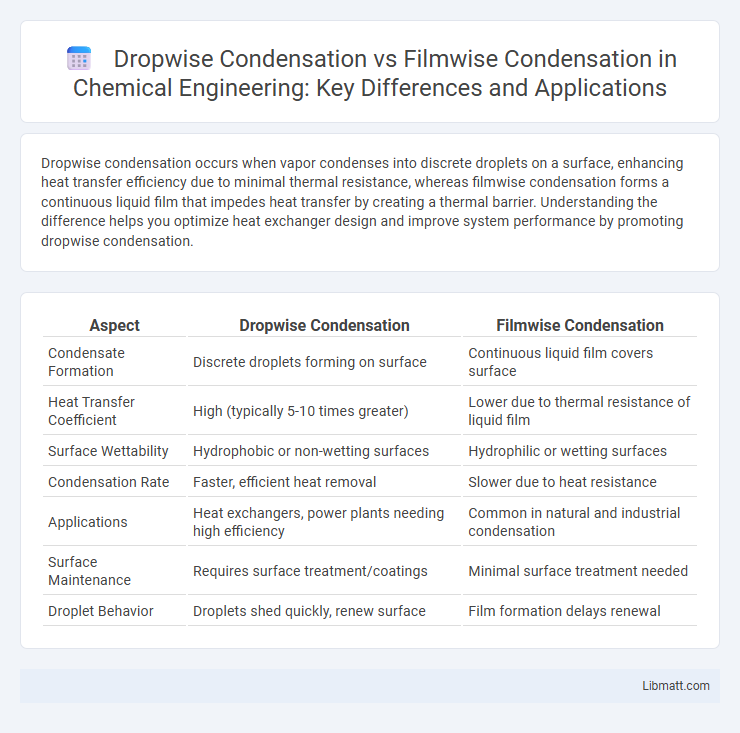

Table of Comparison

| Aspect | Dropwise Condensation | Filmwise Condensation |

|---|---|---|

| Condensate Formation | Discrete droplets forming on surface | Continuous liquid film covers surface |

| Heat Transfer Coefficient | High (typically 5-10 times greater) | Lower due to thermal resistance of liquid film |

| Surface Wettability | Hydrophobic or non-wetting surfaces | Hydrophilic or wetting surfaces |

| Condensation Rate | Faster, efficient heat removal | Slower due to heat resistance |

| Applications | Heat exchangers, power plants needing high efficiency | Common in natural and industrial condensation |

| Surface Maintenance | Requires surface treatment/coatings | Minimal surface treatment needed |

| Droplet Behavior | Droplets shed quickly, renew surface | Film formation delays renewal |

Introduction to Condensation Mechanisms

Dropwise condensation involves the formation of discrete droplets on a surface, enhancing heat transfer by minimizing the thermal resistance of the condensate layer. Filmwise condensation is characterized by a continuous liquid film that forms over the surface, creating higher thermal resistance and reducing heat transfer efficiency. Understanding the differences in condensate morphology and thermal boundary layers is crucial in optimizing heat exchanger performance and designing efficient condensation systems.

What is Dropwise Condensation?

Dropwise condensation is a process where water vapor condenses into discrete droplets on a surface rather than forming a continuous film. This mode of condensation significantly enhances heat transfer efficiency due to the reduced thermal resistance compared to filmwise condensation, where a liquid film impedes heat flow. Your system's performance can be optimized by promoting dropwise condensation through surface treatments that encourage droplet formation and shedding.

What is Filmwise Condensation?

Filmwise condensation occurs when a continuous liquid film forms on a surface as vapor condenses, significantly reducing heat transfer efficiency compared to dropwise condensation. This persistent liquid film creates a thermal resistance barrier, limiting the rate at which heat escapes during the phase change. Understanding filmwise condensation is essential for optimizing heat exchangers, as controlling surface properties can enhance your system's thermal performance.

Key Differences Between Dropwise and Filmwise Condensation

Dropwise condensation occurs when vapor condenses into discrete droplets on a surface, resulting in higher heat transfer coefficients due to minimal thermal resistance. Filmwise condensation forms a continuous liquid film over the surface, which acts as a thermal barrier and significantly reduces heat transfer efficiency. Surface properties, such as hydrophobicity, play a critical role in promoting dropwise condensation, while hydrophilic surfaces typically encourage filmwise condensation.

Heat Transfer Efficiency Comparison

Dropwise condensation offers significantly higher heat transfer efficiency than filmwise condensation due to minimal thermal resistance caused by the absence of a continuous liquid film. In filmwise condensation, the condensate forms a liquid layer that acts as a thermal barrier, reducing the overall heat transfer coefficient by up to ten times compared to dropwise condensation. Enhancing your system with dropwise condensation techniques can dramatically improve heat exchanger performance and energy savings.

Influencing Factors for Each Condensation Type

Surface wettability and temperature differences significantly influence dropwise condensation, promoting discrete droplet formation and enhancing heat transfer rates. Filmwise condensation occurs when surfaces are hydrophilic, causing a continuous liquid film that impedes efficient heat transfer. You can optimize condensation performance by selecting surface coatings and controlling environmental conditions to favor the desired condensation type.

Surface Treatment and Material Considerations

Dropwise condensation is favored on hydrophobic surfaces treated with low surface energy coatings such as fluoropolymers or silanes, which promote droplet formation and maintain high heat transfer efficiency. In contrast, filmwise condensation occurs on hydrophilic or untreated metallic surfaces like copper or aluminum, where a continuous liquid film forms and decreases thermal conductivity. Material selection for condensation applications often emphasizes corrosion resistance and surface energy modulation to optimize phase change heat transfer performance.

Industrial Applications of Dropwise and Filmwise Condensation

Dropwise condensation, characterized by discrete droplets, enhances heat transfer efficiency, making it ideal for industrial applications such as power plant condensers, HVAC systems, and desalination processes. In contrast, filmwise condensation forms a continuous liquid film that acts as a thermal barrier, commonly used in industries requiring corrosion resistance and stable condensate removal, like chemical processing and refrigeration. Optimizing Your system's condensation mode can significantly improve energy savings and operational performance in targeted industrial applications.

Advantages and Disadvantages of Each Method

Dropwise condensation offers higher heat transfer efficiency due to the direct contact of droplets with the surface, reducing thermal resistance and enhancing cooling performance. However, it requires specialized hydrophobic coatings that may degrade over time, leading to potential maintenance challenges. Filmwise condensation, while more robust and easier to maintain under varying conditions, suffers from lower heat transfer rates because the liquid film acts as an insulating layer, reducing overall thermal efficiency.

Future Trends and Research Directions

Dropwise condensation offers superior heat transfer efficiency compared to filmwise condensation, prompting ongoing research into durable, scalable hydrophobic coatings for industrial applications. Future trends emphasize developing nanostructured surfaces and smart materials that sustain dropwise condensation under harsh conditions, enhancing energy savings in power plants and HVAC systems. Advances in computational fluid dynamics and material science aim to optimize condensation patterns and surface longevity, driving innovation in sustainable thermal management technologies.

dropwise condensation vs filmwise condensation Infographic

libmatt.com

libmatt.com