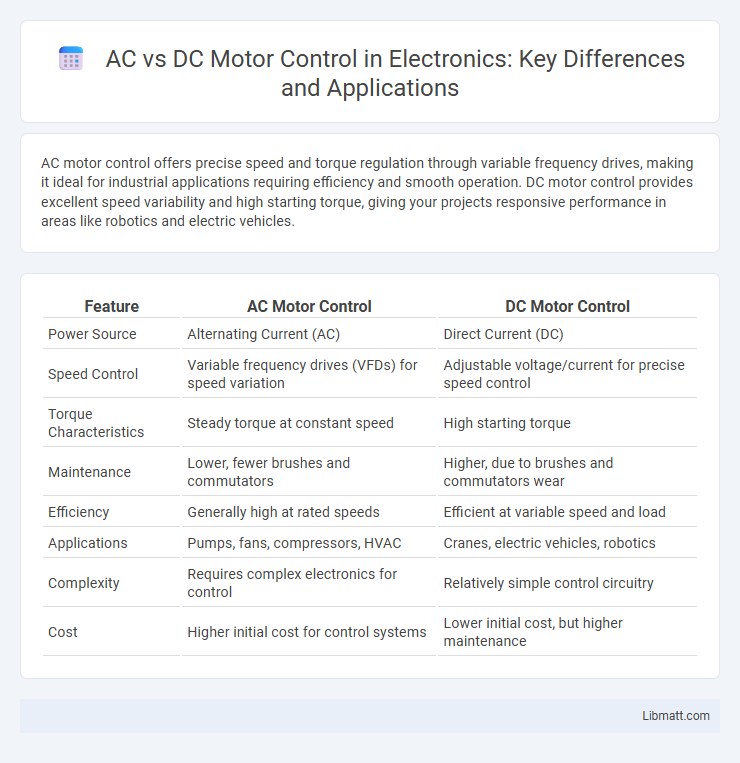

AC motor control offers precise speed and torque regulation through variable frequency drives, making it ideal for industrial applications requiring efficiency and smooth operation. DC motor control provides excellent speed variability and high starting torque, giving your projects responsive performance in areas like robotics and electric vehicles.

Table of Comparison

| Feature | AC Motor Control | DC Motor Control |

|---|---|---|

| Power Source | Alternating Current (AC) | Direct Current (DC) |

| Speed Control | Variable frequency drives (VFDs) for speed variation | Adjustable voltage/current for precise speed control |

| Torque Characteristics | Steady torque at constant speed | High starting torque |

| Maintenance | Lower, fewer brushes and commutators | Higher, due to brushes and commutators wear |

| Efficiency | Generally high at rated speeds | Efficient at variable speed and load |

| Applications | Pumps, fans, compressors, HVAC | Cranes, electric vehicles, robotics |

| Complexity | Requires complex electronics for control | Relatively simple control circuitry |

| Cost | Higher initial cost for control systems | Lower initial cost, but higher maintenance |

Introduction to AC and DC Motor Control

AC and DC motor control involves regulating the speed, torque, and direction of electric motors using different methods tailored to their operation. AC motor control typically employs variable frequency drives (VFDs) to adjust the frequency and voltage supplied to the motor, optimizing performance and energy efficiency. Your choice between AC and DC motor control depends on application requirements, with DC motors offering precise speed control and AC motors favored for durability and low maintenance.

Fundamental Differences Between AC and DC Motors

AC motors operate on alternating current, using electromagnetic induction to create rotational motion, making them efficient for variable speed applications. DC motors run on direct current, relying on a commutator and brushes to maintain unidirectional torque, offering precise speed and torque control. Your choice between AC and DC motor control depends on application requirements such as speed variation, maintenance needs, and control complexity.

Key Principles of Motor Control Systems

AC and DC motor control systems operate based on distinct principles tailored to their power sources and applications. AC motor control utilizes varying frequency and voltage to regulate speed and torque, often employing techniques like Variable Frequency Drives (VFDs) for precise adjustments. DC motor control, in contrast, relies on adjusting the armature voltage or field current to control motor speed and torque, offering fine-tuned performance ideal for applications requiring variable speed and rapid response.

Methods of Speed Control for AC Motors

Speed control of AC motors is commonly achieved through methods such as variable frequency drives (VFDs), which adjust the input frequency to regulate motor speed efficiently. Another approach involves voltage control, where changing the applied voltage affects the speed, primarily in wound-rotor and synchronous motors. For precise and energy-efficient speed regulation, you can utilize vector control techniques that independently manage torque and flux in AC motors.

Techniques for Controlling DC Motor Speed

Pulse Width Modulation (PWM) is a widely used technique for controlling DC motor speed, enabling precise adjustment by varying the duty cycle of voltage applied to the motor. Armature voltage control changes the motor speed through modulation of the input voltage, effectively influencing the torque and rotational velocity. Field flux control adjusts the magnetic field strength within the motor, allowing speed regulation by modifying the motor's electromagnet current.

Starting and Stopping Mechanisms in Motor Control

Starting and stopping mechanisms in AC and DC motor control differ significantly due to their inherent electrical and mechanical characteristics. AC motors typically use methods such as direct-on-line starting, star-delta starters, or soft starters to manage inrush current and ensure smooth acceleration, while stopping often involves applying dynamic braking or coasting. DC motors rely on controlled voltage or current adjustment through specialized controllers like armature voltage control or field weakening for starting and employ regenerative or plugging methods for rapid and precise stopping.

Efficiency Considerations in AC vs. DC Motor Control

AC motor control offers higher efficiency in variable speed applications due to advanced inverter technology and reduced maintenance requirements, resulting in lower operational costs. DC motor control provides precise torque and speed regulation but typically suffers from higher energy losses and brush wear, reducing overall efficiency. Selecting the appropriate motor control depends on balancing efficiency needs with application-specific performance demands.

Common Applications of AC and DC Motor Controllers

AC motor controllers are widely used in industrial applications such as conveyor systems, HVAC fans, and pumps for their ability to efficiently manage variable speed and torque. DC motor controllers excel in applications requiring precise speed control and high starting torque, including electric vehicles, robotics, and elevators. Both types of controllers optimize performance and energy consumption based on the specific demands of their respective applications.

Advanced Motor Control Technologies

Advanced motor control technologies for AC and DC motors leverage sophisticated algorithms such as vector control and field-oriented control (FOC) to enhance torque precision and energy efficiency. These systems integrate real-time sensors and digital signal processors (DSPs) to optimize motor performance under varying load conditions, improving your machinery's responsiveness and operational lifespan. Incorporating IoT connectivity and machine learning further enables predictive maintenance and adaptive control strategies, setting a new standard in motor management solutions.

Selecting the Right Motor Control System

Selecting the right motor control system depends on the application requirements, where AC motor controls excel in variable speed and torque control for industrial machinery, while DC motor controls offer precise speed regulation and high starting torque for applications like robotics and electric vehicles. Consider factors such as efficiency, maintenance needs, and control complexity; AC motor controllers typically feature lower maintenance due to brushless designs, whereas DC motor controllers demand more frequent upkeep but provide superior performance in fine speed adjustments. Evaluating load characteristics, power supply availability, and cost constraints ensures optimal selection between AC and DC motor control systems for enhanced operational efficiency.

AC vs DC motor control Infographic

libmatt.com

libmatt.com