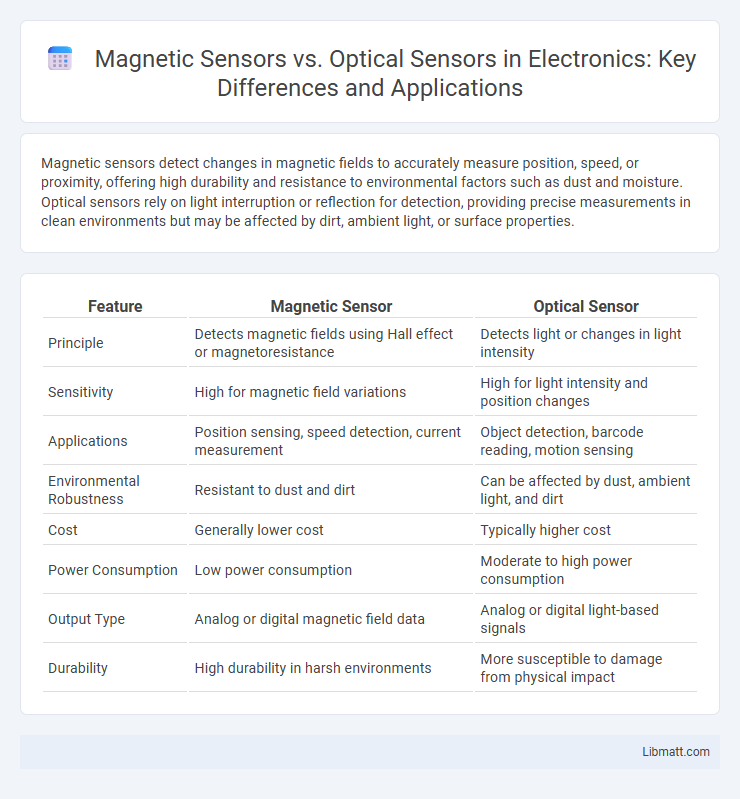

Magnetic sensors detect changes in magnetic fields to accurately measure position, speed, or proximity, offering high durability and resistance to environmental factors such as dust and moisture. Optical sensors rely on light interruption or reflection for detection, providing precise measurements in clean environments but may be affected by dirt, ambient light, or surface properties.

Table of Comparison

| Feature | Magnetic Sensor | Optical Sensor |

|---|---|---|

| Principle | Detects magnetic fields using Hall effect or magnetoresistance | Detects light or changes in light intensity |

| Sensitivity | High for magnetic field variations | High for light intensity and position changes |

| Applications | Position sensing, speed detection, current measurement | Object detection, barcode reading, motion sensing |

| Environmental Robustness | Resistant to dust and dirt | Can be affected by dust, ambient light, and dirt |

| Cost | Generally lower cost | Typically higher cost |

| Power Consumption | Low power consumption | Moderate to high power consumption |

| Output Type | Analog or digital magnetic field data | Analog or digital light-based signals |

| Durability | High durability in harsh environments | More susceptible to damage from physical impact |

Introduction to Magnetic and Optical Sensors

Magnetic sensors detect changes in magnetic fields to measure position, speed, or current, offering durability and high accuracy in harsh environments. Optical sensors use light, such as infrared or laser beams, to detect objects, measure distance, or recognize patterns with high precision and fast response times. Your choice between magnetic and optical sensors depends on the specific application requirements, including environmental conditions and desired sensitivity.

Working Principles of Magnetic Sensors

Magnetic sensors operate based on the detection of magnetic fields through changes in electrical properties such as resistance, inductance, or Hall voltage, enabling precise measurement of position, speed, or current. Unlike optical sensors that rely on light interruption or reflection, magnetic sensors use principles like the Hall effect, magnetoresistance, or fluxgate technology to convert magnetic field variations into electrical signals. Your choice of sensor depends on the application environment, with magnetic sensors excelling in harsh conditions and providing contactless measurement capabilities.

Working Principles of Optical Sensors

Optical sensors operate by detecting changes in light intensity, wavelength, or phase to measure physical properties such as distance, position, or color. These sensors typically use components like photodiodes, LEDs, or lasers to emit and receive light signals, converting optical information into electrical signals for analysis. Your choice of optical sensor depends on factors like sensitivity, response time, and the specific application environment where precise light detection is required.

Key Differences: Magnetic vs Optical Sensors

Magnetic sensors detect changes in magnetic fields using Hall effect or magnetoresistive technologies, providing robust performance in harsh environments and through non-metallic barriers. Optical sensors rely on light modulation, such as infrared or laser beams, to detect object presence or measure distance with high precision and speed but can be affected by dust, smoke, or ambient light. Your choice between magnetic and optical sensors depends on application requirements like environmental conditions, sensitivity, and response time.

Accuracy and Sensitivity Comparison

Magnetic sensors offer high sensitivity to changes in magnetic fields, making them effective for detecting position and rotational speed with moderate accuracy in environments with magnetic interference. Optical sensors provide superior accuracy and resolution by detecting changes in light intensity or patterns, ideal for precise measurements in clean, unobstructed settings. Your choice between magnetic and optical sensors should consider the application's tolerance for environmental noise and the required precision level.

Common Applications of Magnetic Sensors

Magnetic sensors are widely used in industrial automation, automotive systems for wheel speed detection, and consumer electronics such as smartphones and wearables for position sensing. Their ability to detect changes in magnetic fields makes them ideal for applications requiring non-contact measurement of rotational speed, current, or proximity. Your choice of a magnetic sensor ensures reliable performance in harsh environments where optical sensors might fail due to dust, dirt, or light interference.

Common Applications of Optical Sensors

Optical sensors are widely used in applications such as barcode scanners, fiber optic communication, and motion detection systems due to their high precision in detecting light intensity and wavelength changes. In industrial automation, optical sensors enable non-contact measurement and quality control, ensuring accurate positioning and object recognition. Their ability to detect subtle variations in light makes them essential for medical imaging devices and environmental monitoring systems.

Advantages and Limitations of Each Sensor Type

Magnetic sensors offer high durability and excellent performance in harsh environments due to their resistance to dirt, dust, and moisture, making them ideal for industrial and automotive applications, but they may suffer from limited range and sensitivity compared to optical sensors. Optical sensors provide superior accuracy and fast response times, especially in applications requiring precise position, proximity, or motion detection, yet their performance can be degraded by environmental factors such as fog, dust, or ambient light interference. Selecting between magnetic and optical sensors depends on balancing the need for environmental robustness versus accuracy and speed in specific use cases.

Cost and Durability Considerations

Magnetic sensors typically offer lower costs and higher durability due to their resistance to dust, dirt, and moisture, making them ideal for harsh environments. Optical sensors, while generally more expensive, can provide higher precision but are more vulnerable to environmental factors such as dirt accumulation and physical damage. Cost efficiency and long-term reliability often make magnetic sensors the preferred choice in industrial and automotive applications.

Choosing the Right Sensor: Magnetic or Optical?

Magnetic sensors excel in harsh environments with dust, dirt, and moisture, offering durability and reliability for industrial applications. Optical sensors provide high precision and fast response times, ideal for detecting fine details and color variations in controlled settings. Selecting the right sensor depends on environmental conditions, required accuracy, and specific application needs such as proximity detection or object recognition.

Magnetic Sensor vs Optical Sensor Infographic

libmatt.com

libmatt.com