Bulkhead connectors secure electrical connections through a panel or enclosure, providing a sturdy interface resistant to environmental factors, while panel mount connectors are designed to be fixed directly onto the surface, offering easy access and installation. Understanding the difference helps you select the appropriate connector type for ensuring reliable mechanical and electrical performance in your device.

Table of Comparison

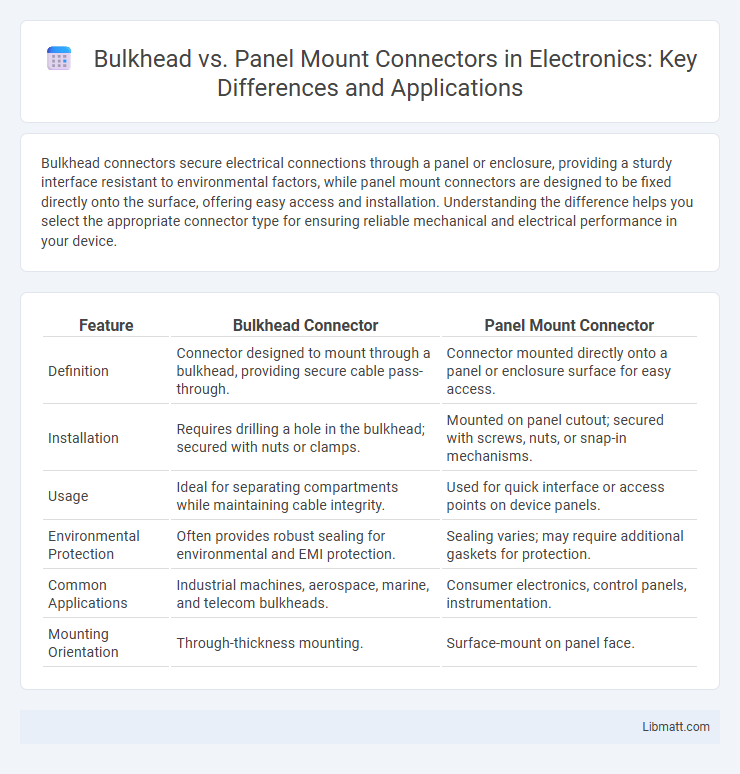

| Feature | Bulkhead Connector | Panel Mount Connector |

|---|---|---|

| Definition | Connector designed to mount through a bulkhead, providing secure cable pass-through. | Connector mounted directly onto a panel or enclosure surface for easy access. |

| Installation | Requires drilling a hole in the bulkhead; secured with nuts or clamps. | Mounted on panel cutout; secured with screws, nuts, or snap-in mechanisms. |

| Usage | Ideal for separating compartments while maintaining cable integrity. | Used for quick interface or access points on device panels. |

| Environmental Protection | Often provides robust sealing for environmental and EMI protection. | Sealing varies; may require additional gaskets for protection. |

| Common Applications | Industrial machines, aerospace, marine, and telecom bulkheads. | Consumer electronics, control panels, instrumentation. |

| Mounting Orientation | Through-thickness mounting. | Surface-mount on panel face. |

Introduction to Bulkhead and Panel Mount Connectors

Bulkhead connectors are designed for secure, robust attachment through a panel, providing reliable electrical connections in industrial and marine environments. Panel mount connectors are installed directly onto equipment panels, offering easy access and streamlined integration for control systems and electronic devices. Understanding your application's space and durability requirements helps determine the best option between bulkhead and panel mount connectors.

Defining Bulkhead Connectors

Bulkhead connectors are designed to securely attach to a panel or enclosure, providing a stable and accessible interface for electrical connections. These connectors enable easy separation of wiring between two environments while maintaining a robust seal against dust, moisture, and mechanical stress. Your choice of bulkhead connectors ensures reliable connectivity in applications requiring frequent mating and unmating across mounting surfaces.

Overview of Panel Mount Connectors

Panel mount connectors are designed to be securely installed on equipment enclosures, providing a stable interface for external connection while maintaining the integrity of the device casing. These connectors typically feature mounting flanges or threaded nuts, ensuring a robust attachment that resists vibration and mechanical stress in industrial or automotive applications. Your choice of panel mount connectors should consider factors such as environmental sealing, electrical performance, and ease of installation to support reliable and durable connectivity.

Key Differences: Bulkhead vs Panel Mount

Bulkhead connectors are designed to pass through a chassis or enclosure, providing a secure connection point on the bulkhead or wall, while panel mount connectors attach directly to a control panel or equipment face for easy access and interface. Bulkhead connectors typically offer robust mechanical stability for cable entry points, whereas panel mount connectors emphasize user accessibility and quick connection or disconnection. Your choice depends on whether you prioritize structural integrity through an enclosure or convenient panel-level connectivity.

Typical Applications for Bulkhead Connectors

Bulkhead connectors are commonly used in aerospace, military, and industrial equipment where secure, sealed connections are essential for passing cables through panels or bulkheads. They provide robust mechanical support and environmental protection in harsh conditions, making them ideal for applications such as avionics systems, outdoor telecommunications, and marine electronics. Their design facilitates easy maintenance and ensures signal integrity in critical communication and power transfer scenarios.

Common Uses of Panel Mount Connectors

Panel mount connectors are frequently used in industrial control systems, telecommunications equipment, and audio/video devices to provide secure and accessible connections on equipment panels. These connectors offer easy maintenance and replacement without disrupting internal wiring, making them ideal for applications requiring frequent connection changes. You benefit from their robust design and reliable performance in environments where stability and accessibility are critical.

Installation Comparison: Bulkhead vs Panel Mount

Bulkhead connectors install through a device's enclosure, offering secure, sealed connections by mounting directly to a bulkhead or chassis panel, ideal for rugged environments requiring strong mechanical stability and environmental protection. Panel mount connectors, by contrast, are designed to fasten onto flat surfaces with visible mounting flanges and are generally easier to replace or access but may provide less environmental sealing compared to bulkhead types. Choosing between bulkhead and panel mount connectors depends on the application's mechanical strength requirements, ease of maintenance, and the required level of protection against dust, moisture, and vibration.

Pros and Cons of Bulkhead Connectors

Bulkhead connectors offer robust mechanical support and secure cable connections by mounting directly on a panel, ensuring reliable signal integrity in demanding environments. They provide excellent environmental sealing and strain relief, making them ideal for industrial and aerospace applications, but their installation requires precise panel cutouts and can be time-consuming. Limited flexibility in repositioning and potential for increased maintenance complexity represent trade-offs compared to panel mount connectors.

Advantages and Limitations of Panel Mount Connectors

Panel mount connectors offer reliable secure connections by being fixed directly to the enclosure, which improves durability and stability in harsh environments. Their design allows easy access for maintenance and replacement without disrupting the internal wiring, enhancing operational efficiency. However, these connectors require precise installation and sufficient panel space, and may increase manufacturing complexity and cost.

Choosing the Right Connector for Your Project

Selecting between bulkhead and panel mount connectors depends on the installation environment and mechanical stability requirements. Bulkhead connectors offer robust, secure mounting through a chassis or bulkhead, ideal for applications needing strong, vibration-resistant connections. Panel mount connectors provide easier access and maintenance on equipment surfaces, making them suitable for user interfaces where frequent connection changes occur.

Bulkhead vs Panel Mount Connector Infographic

libmatt.com

libmatt.com