Chip resistors offer compact size and high precision for low-power applications, while wirewound resistors provide superior power handling and stability in high-current circuits. Choosing the right resistor depends on your circuit's power requirements and tolerance for heat dissipation.

Table of Comparison

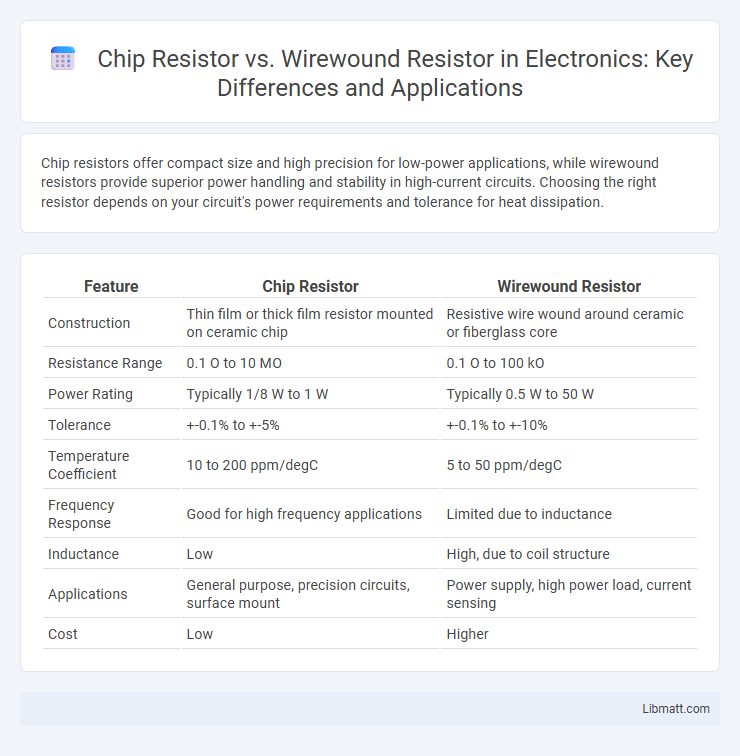

| Feature | Chip Resistor | Wirewound Resistor |

|---|---|---|

| Construction | Thin film or thick film resistor mounted on ceramic chip | Resistive wire wound around ceramic or fiberglass core |

| Resistance Range | 0.1 O to 10 MO | 0.1 O to 100 kO |

| Power Rating | Typically 1/8 W to 1 W | Typically 0.5 W to 50 W |

| Tolerance | +-0.1% to +-5% | +-0.1% to +-10% |

| Temperature Coefficient | 10 to 200 ppm/degC | 5 to 50 ppm/degC |

| Frequency Response | Good for high frequency applications | Limited due to inductance |

| Inductance | Low | High, due to coil structure |

| Applications | General purpose, precision circuits, surface mount | Power supply, high power load, current sensing |

| Cost | Low | Higher |

Introduction to Chip Resistors and Wirewound Resistors

Chip resistors are surface-mount components composed of a resistive film deposited on a ceramic substrate, designed for precise resistance values in compact electronic circuits. Wirewound resistors consist of a metal wire wound around an insulating core, offering high power ratings and excellent accuracy for applications requiring reliable heat dissipation. Both resistor types serve distinct roles in electronic designs based on power handling, size constraints, and precision requirements.

Construction and Materials: A Comparative Overview

Chip resistors use a thin-film or thick-film resistive element deposited on a ceramic substrate, offering compact size and stability. Wirewound resistors consist of a metal wire, typically nichrome or copper-nickel alloy, wound around an insulating core, providing high power dissipation and precision. The choice of materials influences their electrical performance, thermal stability, and application suitability, with chip resistors favored for miniaturization and wirewound resistors for high power handling.

Electrical Properties and Performance Differences

Chip resistors offer high precision and low inductance, making them ideal for high-frequency applications with stable resistance over a wide temperature range. Wirewound resistors provide superior power dissipation and tolerance to high surge currents but exhibit higher inductance and slower response times. The choice between chip and wirewound resistors depends on the application's requirements for accuracy, power handling, and signal integrity.

Power Handling Capabilities

Chip resistors typically handle power ratings from 0.05W to 1W, making them suitable for low to moderate power applications in compact electronic circuits. Wirewound resistors offer significantly higher power handling capabilities, ranging from 1W up to several hundred watts, due to their robust construction with wire coils providing excellent heat dissipation. These higher power ratings make wirewound resistors ideal for load testing, power supplies, and industrial equipment where greater energy dissipation is essential.

Precision and Tolerance Ratings

Chip resistors offer high precision with tolerance ratings as low as +-0.1%, making them ideal for applications requiring exact resistance values. Wirewound resistors, while durable and capable of handling higher power, typically have wider tolerance ranges starting around +-1%, which may limit their use in precision circuits. Your choice between the two depends on whether tight tolerance or power handling is the primary requirement.

Size, Packaging, and Mounting Options

Chip resistors offer compact size with surface-mount packaging, ideal for high-density electronic circuits, while wirewound resistors typically have larger, bulkier cylindrical or rectangular forms designed for higher power dissipation. Chip resistors are primarily available in standard surface-mount device (SMD) packages like 0402 or 0805, enabling automated PCB assembly, whereas wirewound resistors come in through-hole, axial, or power resistor packages suited for manual or heavy-duty applications. Mounting options for chip resistors emphasize soldering on PCB pads, contrasting with wirewound resistors which support screw terminals, clamps, or PCB mounting with reinforced leads for robust mechanical and thermal stability.

Applications and Use Cases

Chip resistors are ideal for high-frequency circuits and precision applications in consumer electronics, telecommunications, and automotive systems due to their compact size and stability. Wirewound resistors excel in power handling and heat dissipation, making them suitable for power supplies, motor drives, and industrial equipment requiring high load tolerance. Their distinct characteristics determine suitability: chip resistors for signal integrity and miniaturization, wirewound resistors for high power and durability.

Reliability and Durability Considerations

Chip resistors offer high reliability and durability in applications requiring stable resistance under thermal stress due to their compact size and advanced material composition. Wirewound resistors excel in durability for high-power settings, providing superior heat dissipation and maintaining performance over extended use with minimal resistance drift. Choosing between these resistor types depends on your specific requirements for power rating, environmental conditions, and long-term stability.

Cost Analysis: Chip Resistor vs Wirewound Resistor

Chip resistors generally offer lower manufacturing and material costs compared to wirewound resistors, making them more economical for high-volume, low-power applications. Wirewound resistors, constructed with a metal wire coil, involve higher production expenses due to complex winding processes and premium materials, but provide superior power dissipation and precision. Cost analysis favors chip resistors for budget-sensitive projects, while wirewound resistors justify higher prices with enhanced performance in high-power scenarios.

Choosing the Right Resistor for Your Project

Selecting the right resistor involves evaluating power rating, tolerance, and frequency response; chip resistors excel in low-power, high-frequency circuits due to their precise, compact design, while wirewound resistors are ideal for high-power applications requiring robust heat dissipation and stability. Wirewound resistors offer superior inductive characteristics suitable for filtering and current sensing, whereas chip resistors provide low inductance and fast response ideal for surface-mount technology. Careful consideration of electrical specifications, thermal management, and environmental conditions ensures optimal performance and reliability in electronic projects.

Chip Resistor vs Wirewound Resistor Infographic

libmatt.com

libmatt.com