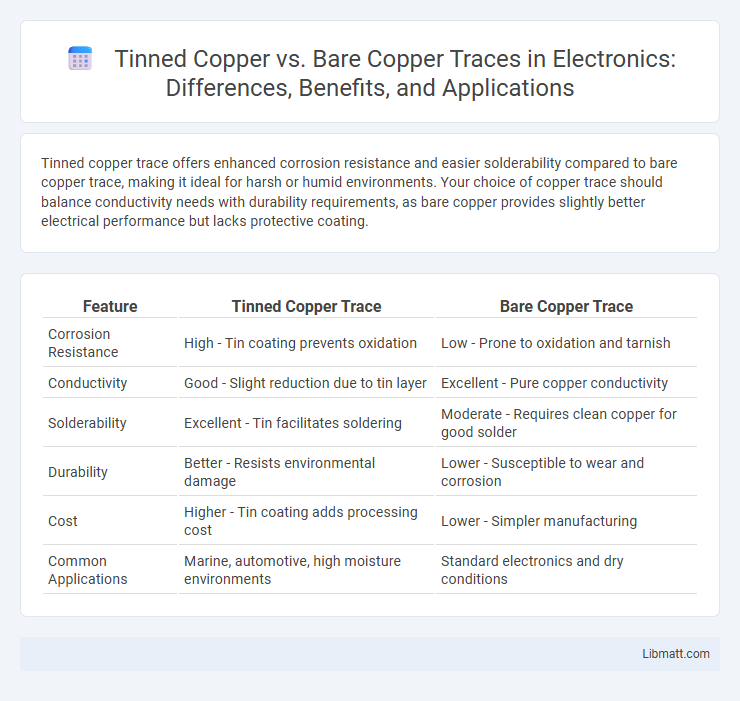

Tinned copper trace offers enhanced corrosion resistance and easier solderability compared to bare copper trace, making it ideal for harsh or humid environments. Your choice of copper trace should balance conductivity needs with durability requirements, as bare copper provides slightly better electrical performance but lacks protective coating.

Table of Comparison

| Feature | Tinned Copper Trace | Bare Copper Trace |

|---|---|---|

| Corrosion Resistance | High - Tin coating prevents oxidation | Low - Prone to oxidation and tarnish |

| Conductivity | Good - Slight reduction due to tin layer | Excellent - Pure copper conductivity |

| Solderability | Excellent - Tin facilitates soldering | Moderate - Requires clean copper for good solder |

| Durability | Better - Resists environmental damage | Lower - Susceptible to wear and corrosion |

| Cost | Higher - Tin coating adds processing cost | Lower - Simpler manufacturing |

| Common Applications | Marine, automotive, high moisture environments | Standard electronics and dry conditions |

Introduction to Tinned Copper and Bare Copper Traces

Tinned copper traces feature a thin layer of tin coating over bare copper to enhance corrosion resistance and solderability in electronic circuits. Bare copper traces consist solely of pure copper, known for its excellent electrical conductivity but requiring protective measures against oxidation. The choice between tinned and bare copper traces impacts the durability, performance, and manufacturing process of printed circuit boards (PCBs).

Composition and Manufacturing Differences

Tinned copper consists of bare copper conductors coated with a thin layer of tin to prevent oxidation and enhance solderability, while bare copper is simply pure copper without any coating. The manufacturing process of tinned copper involves an additional electroplating or hot-dipping step to apply the tin layer uniformly over the copper strands. Your choice between tinned copper and bare copper traces depends on the application environment, with tinned copper offering better corrosion resistance and bare copper providing superior conductivity.

Electrical Conductivity Comparison

Tinned copper traces exhibit slightly lower electrical conductivity compared to bare copper traces due to the thin layer of tin coating, which has higher resistivity than copper. Bare copper traces provide superior conductivity, making them ideal for applications requiring minimal resistance and efficient current flow. However, tinned copper offers enhanced corrosion resistance, which can maintain stable conductivity over time in harsh environments.

Corrosion Resistance and Longevity

Tinned copper traces exhibit superior corrosion resistance compared to bare copper due to their protective tin coating, which prevents oxidation and extends the lifespan of electronic components exposed to harsh environments. Bare copper, while highly conductive, is more susceptible to corrosion and oxidation, leading to potential signal degradation over time. Selecting tinned copper can enhance the durability and reliability of your circuitry, especially in applications involving moisture or chemical exposure.

Solderability and Assembly Efficiency

Tinned copper traces offer superior solderability due to their pre-coated surface that resists oxidation, ensuring consistent wetting and stronger solder joints during assembly. This results in higher assembly efficiency by reducing soldering defects and rework time compared to bare copper traces, which require additional surface preparation to achieve reliable solder bonds. The enhanced protection and ease of soldering with tinned copper significantly improve manufacturing throughput and overall product quality.

Cost Analysis: Tinned vs Bare Copper

Tinned copper traces generally incur higher material and processing costs than bare copper due to the additional tin coating process, increasing overall expenses by approximately 10-20%. Bare copper offers a cost-effective solution with lower raw material and manufacturing expenses, favored in budget-sensitive applications. However, tinned copper's enhanced corrosion resistance and solderability may reduce long-term maintenance costs, potentially offsetting initial higher investments in harsh environments.

Applications in PCB Design

Tinned copper traces offer enhanced corrosion resistance, making them ideal for PCBs used in humid or marine environments, while bare copper provides superior electrical conductivity preferred in high-performance and high-frequency applications. In PCB design, tinned copper improves solderability and extends shelf life, which is critical for long-term reliability in consumer electronics and aerospace sectors. Bare copper traces are favored in RF and power circuits where minimal signal loss and maximum current capacity are essential.

Performance in Harsh Environments

Tinned copper traces exhibit superior corrosion resistance and oxidation protection compared to bare copper, making them ideal for harsh environments such as marine or industrial applications exposed to moisture and chemicals. Bare copper, while offering excellent electrical conductivity, tends to oxidize quickly, leading to increased resistance and potential failure under prolonged exposure to aggressive conditions. The tin coating on tinned copper extends the lifespan of electronic traces by maintaining solderability and conductivity in extreme temperatures and humid atmospheres.

Maintenance and Reliability Factors

Tinned copper traces offer superior corrosion resistance compared to bare copper, reducing maintenance frequency and improving long-term reliability in humid or corrosive environments. The tin coating acts as a protective barrier, preventing oxidation that commonly degrades bare copper traces and leads to potential circuit failures. This enhanced durability makes tinned copper the preferred choice for applications demanding consistent performance and lower upkeep costs.

Making the Right Choice for Your Project

Tinned copper traces offer enhanced corrosion resistance and longer lifespan, making them ideal for projects exposed to moisture or harsh environments. Bare copper traces provide superior electrical conductivity and lower costs, which are beneficial for applications demanding high performance and budget efficiency. Assess your project's environmental conditions and performance requirements to determine whether tinned or bare copper traces best suit your needs.

Tinned copper vs Bare copper trace Infographic

libmatt.com

libmatt.com