A PI controller adjusts system output by correcting proportional and integral errors, effectively eliminating steady-state offset but lacking the predictive control provided by the derivative term in a PID controller. Your system benefits from a PID controller when faster response and improved stability are needed, as the derivative action anticipates future errors and enhances overall control performance.

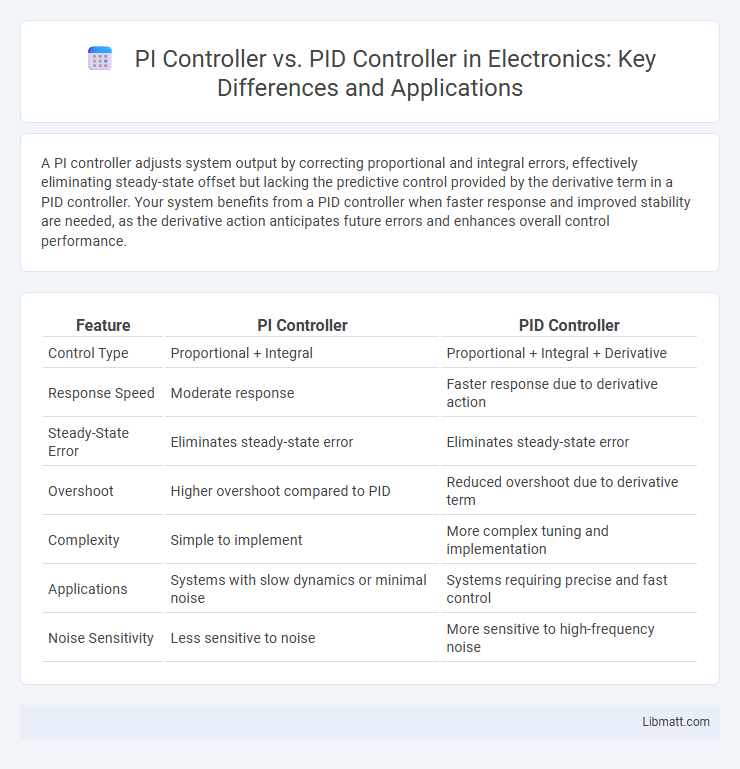

Table of Comparison

| Feature | PI Controller | PID Controller |

|---|---|---|

| Control Type | Proportional + Integral | Proportional + Integral + Derivative |

| Response Speed | Moderate response | Faster response due to derivative action |

| Steady-State Error | Eliminates steady-state error | Eliminates steady-state error |

| Overshoot | Higher overshoot compared to PID | Reduced overshoot due to derivative term |

| Complexity | Simple to implement | More complex tuning and implementation |

| Applications | Systems with slow dynamics or minimal noise | Systems requiring precise and fast control |

| Noise Sensitivity | Less sensitive to noise | More sensitive to high-frequency noise |

Introduction to PI and PID Controllers

PI controllers combine proportional and integral actions to eliminate steady-state error and improve system stability, making them effective in processes with minimal dynamic complexity. PID controllers extend PI functionality by adding a derivative term that predicts system behavior, enhancing response speed and reducing overshoot in dynamic and nonlinear systems. Both controllers are fundamental in control engineering for regulating variables like temperature, pressure, and flow, but PID offers greater precision in complex applications.

Basic Concepts of Control Systems

A PI controller combines proportional and integral actions to eliminate steady-state error and improve system stability, making it ideal for processes with minimal disturbance and slower dynamics. PID controllers include an additional derivative term to predict future errors, enhancing response speed and reducing overshoot in complex and fast-changing systems. Your choice between PI and PID depends on the precise control requirements, system behavior, and desired performance in your control system.

Overview of PI (Proportional-Integral) Controller

A PI (Proportional-Integral) controller combines proportional control to react to current errors and integral control to eliminate accumulated past errors, improving system stability and accuracy. It is widely used in processes with slow dynamics where reducing steady-state error is critical but derivative action is unnecessary or too sensitive to noise. Your control system benefits from a PI controller by achieving smoother, more accurate responses without the complexity of full PID control.

Overview of PID (Proportional-Integral-Derivative) Controller

PID controllers combine proportional, integral, and derivative control actions to continuously adjust system output for desired setpoint accuracy and stability. The proportional component addresses present error, the integral eliminates accumulated past errors, and the derivative predicts future error trends to reduce overshoot. This combination enables precise, responsive, and stable control in diverse industrial and automation applications.

Key Differences Between PI and PID Controllers

PI controllers use proportional and integral actions to eliminate steady-state error and improve system stability, making them ideal for systems with slower dynamics. PID controllers add a derivative component that predicts future errors based on the rate of change, enhancing response speed and reducing overshoot in more complex or faster systems. Your choice depends on the specific control requirements, where PI suits simpler applications and PID offers superior performance in precision and responsiveness.

Advantages of PI Controllers

PI controllers offer simpler tuning and implementation compared to PID controllers, making them ideal for systems where derivative action is unnecessary or noisy. They effectively eliminate steady-state error by combining proportional and integral control, enhancing system stability and accuracy. Your control system benefits from reduced complexity and maintenance while maintaining robust performance in many industrial applications.

Advantages of PID Controllers

PID controllers offer superior control precision by combining proportional, integral, and derivative actions to minimize error, reduce overshoot, and improve system stability. Their ability to anticipate system behavior through the derivative term enhances response time and reduces oscillations compared to PI controllers, which lack this predictive capability. Your control systems benefit from increased adaptability and robustness, making PID controllers ideal for complex, dynamic processes requiring fine-tuned performance.

Typical Applications of PI vs PID Controllers

PI controllers are widely used in applications where eliminating steady-state error is critical, such as temperature control, level control, and flow systems in industrial processes. PID controllers find typical applications in systems requiring precise control and rapid response, including motor speed control, robotics, and aerospace engineering, where both transient and steady-state performance matter. Your choice depends on whether your system demands simple error correction or more complex dynamic control to handle varying disturbances.

How to Choose Between PI and PID Controllers

Choosing between PI and PID controllers depends on your system's requirements for accuracy and stability. PI controllers excel in eliminating steady-state error in processes with negligible oscillations, while PID controllers add derivative action to improve response time and reduce overshoot in more dynamic or complex systems. Your selection should consider the trade-off between simplicity and control precision, especially in environments sensitive to noise and changes.

Conclusion: Which Controller Fits Your Needs?

A PI controller suits systems requiring steady-state error elimination without the complexity of derivative action, making it ideal for processes with minimal noise and slower dynamics. A PID controller offers enhanced performance by incorporating derivative control to improve stability and transient response, benefiting systems with rapid changes or disturbances. Selecting between PI and PID depends on system dynamics, noise sensitivity, and the need for precise control versus simplicity.

PI controller vs PID controller Infographic

libmatt.com

libmatt.com