Coreless transformers offer reduced core losses and minimize electromagnetic interference, making them ideal for high-frequency applications, while iron core transformers provide better magnetic flux concentration and efficiency for low-frequency power transmission. Choosing the right transformer depends on Your specific needs for energy efficiency, size, and operating frequency.

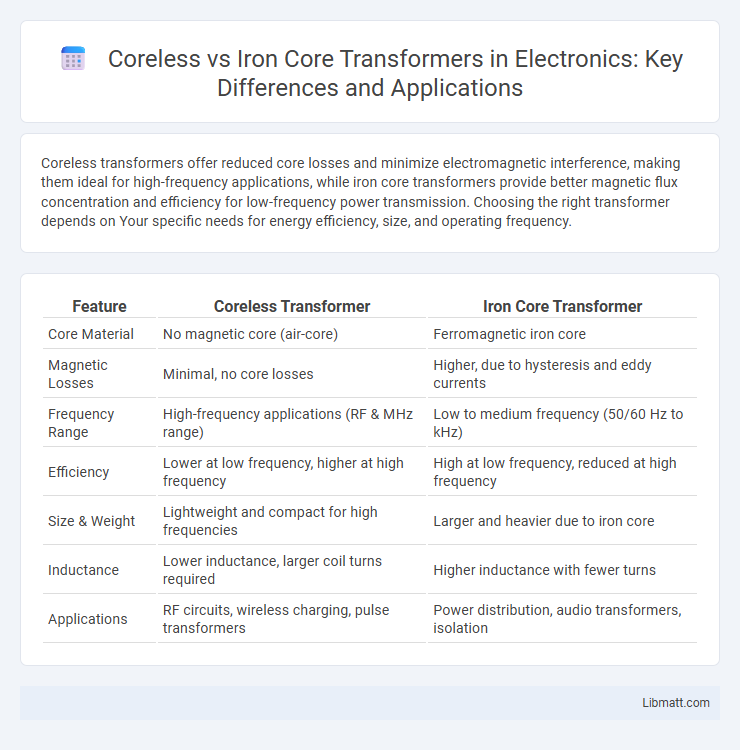

Table of Comparison

| Feature | Coreless Transformer | Iron Core Transformer |

|---|---|---|

| Core Material | No magnetic core (air-core) | Ferromagnetic iron core |

| Magnetic Losses | Minimal, no core losses | Higher, due to hysteresis and eddy currents |

| Frequency Range | High-frequency applications (RF & MHz range) | Low to medium frequency (50/60 Hz to kHz) |

| Efficiency | Lower at low frequency, higher at high frequency | High at low frequency, reduced at high frequency |

| Size & Weight | Lightweight and compact for high frequencies | Larger and heavier due to iron core |

| Inductance | Lower inductance, larger coil turns required | Higher inductance with fewer turns |

| Applications | RF circuits, wireless charging, pulse transformers | Power distribution, audio transformers, isolation |

Introduction to Transformers

Transformers are electrical devices used to transfer energy between circuits through electromagnetic induction, with core types significantly influencing performance. Coreless transformers lack a magnetic core, resulting in less inductance and reduced efficiency but offer lightweight and high-frequency operation advantages. Iron core transformers contain laminated iron cores that enhance magnetic flux, improving efficiency and power handling, making them ideal for power distribution and heavy-duty applications.

What is a Coreless Transformer?

A coreless transformer is an electrical transformer that operates without a magnetic core, using air or vacuum to provide inductive coupling between its primary and secondary windings. This design eliminates core losses such as hysteresis and eddy currents, resulting in higher efficiency and reduced weight compared to iron core transformers. Coreless transformers are ideal for high-frequency applications and sensitive electronics where minimal electromagnetic interference and compact size are critical.

What is an Iron Core Transformer?

An iron core transformer uses a laminated iron core to efficiently transfer magnetic flux between the primary and secondary coils, enhancing energy transfer and minimizing losses. This core material significantly improves the transformer's performance by providing a low-reluctance path for the magnetic field, supporting higher power applications. Understanding the role of the iron core helps you select the right transformer for your electrical systems requiring reliable voltage regulation and efficiency.

Key Differences Between Coreless and Iron Core Transformers

Coreless transformers eliminate magnetic cores, relying on air or vacuum to transfer energy, resulting in reduced core losses and minimal electromagnetic interference, whereas iron core transformers use laminated iron cores to enhance magnetic flux and improve efficiency with higher power handling capabilities. Coreless designs are typically lighter, smaller, and ideal for high-frequency applications, while iron core transformers are preferred for low-frequency power distribution due to their superior magnetic permeability and robustness. The choice between coreless and iron core transformers depends on factors such as operational frequency, efficiency requirements, size constraints, and application-specific demands.

Construction and Design Comparison

Coreless transformers utilize air or non-magnetic materials as the magnetic circuit, resulting in a lightweight and compact design with minimal core losses. Iron core transformers incorporate laminated iron cores to concentrate magnetic flux, enhancing efficiency and reducing energy loss through improved magnetic coupling. Your choice between these designs depends on application needs, such as size constraints or efficiency priorities.

Efficiency and Performance Analysis

Coreless transformers exhibit lower efficiency compared to iron core transformers due to higher leakage inductance and reduced magnetic flux confinement, which leads to increased energy losses. Iron core transformers benefit from high magnetic permeability of the iron core, enhancing flux linkage and minimizing core losses, resulting in superior performance and energy efficiency. Performance analysis reveals that iron core transformers are preferred for high-power applications, while coreless transformers suit high-frequency, low-power scenarios where reduced eddy current losses and electromagnetic interference are critical.

Applications of Coreless Transformers

Coreless transformers are primarily used in applications requiring minimal electromagnetic interference and compact design, such as wireless power transfer systems and biomedical devices. Their air-core construction eliminates core losses, making them ideal for high-frequency signal isolation and precision measurement instruments. Industrial sectors benefit from coreless transformers in high-frequency inductors and pulse transformers where efficiency and reduced noise are critical.

Applications of Iron Core Transformers

Iron core transformers are widely used in power distribution and electrical grid applications due to their high magnetic permeability, which enhances energy efficiency and reduces core losses. These transformers are essential in industrial machinery, where stable voltage regulation and reliable power transmission are critical for motors, generators, and heavy electrical equipment. Their robust design and ability to handle high power loads make them ideal for commercial and utility-scale electrical infrastructure.

Advantages and Disadvantages

Coreless transformers offer advantages such as reduced size, lighter weight, and minimal core losses due to the absence of a magnetic core, making them ideal for high-frequency applications and sensitive electronic devices. However, they suffer from lower efficiency and limited power capacity compared to iron core transformers, which provide higher magnetic permeability, better flux confinement, and improved energy transfer efficiency. Your choice depends on the specific application requirements, balancing the compactness and frequency performance of coreless designs against the robustness and power handling ability of iron core transformers.

Which Transformer Type is Best for Your Needs?

Coreless transformers provide high efficiency and low electromagnetic interference, making them ideal for sensitive electronic equipment requiring lightweight and compact designs. Iron core transformers offer superior magnetic flux management and are better suited for high-power applications with stable voltage regulation needs. Assess your energy requirements and space constraints to determine whether coreless or iron core transformers best match your operational demands.

Coreless vs Iron core transformer Infographic

libmatt.com

libmatt.com