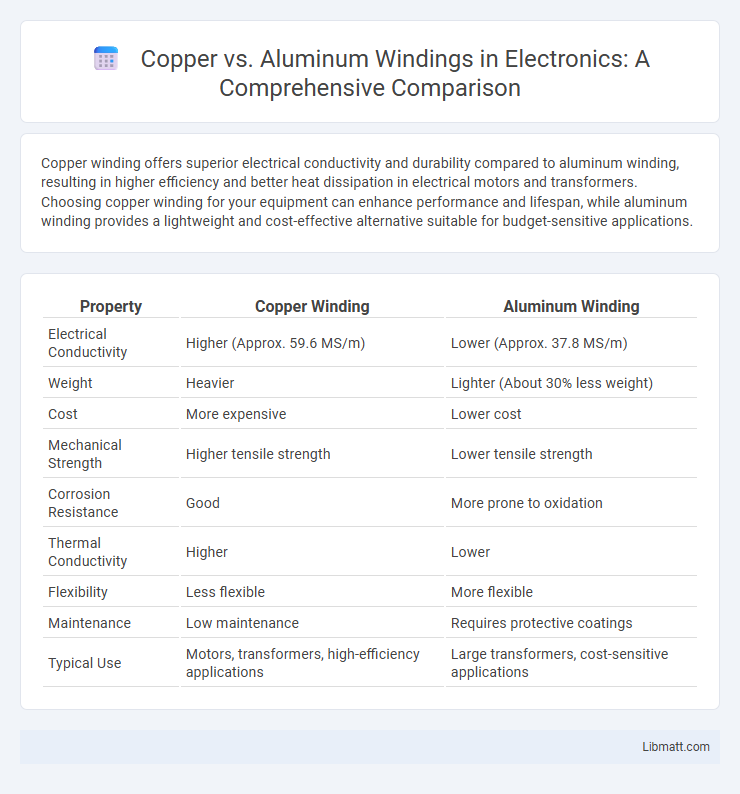

Copper winding offers superior electrical conductivity and durability compared to aluminum winding, resulting in higher efficiency and better heat dissipation in electrical motors and transformers. Choosing copper winding for your equipment can enhance performance and lifespan, while aluminum winding provides a lightweight and cost-effective alternative suitable for budget-sensitive applications.

Table of Comparison

| Property | Copper Winding | Aluminum Winding |

|---|---|---|

| Electrical Conductivity | Higher (Approx. 59.6 MS/m) | Lower (Approx. 37.8 MS/m) |

| Weight | Heavier | Lighter (About 30% less weight) |

| Cost | More expensive | Lower cost |

| Mechanical Strength | Higher tensile strength | Lower tensile strength |

| Corrosion Resistance | Good | More prone to oxidation |

| Thermal Conductivity | Higher | Lower |

| Flexibility | Less flexible | More flexible |

| Maintenance | Low maintenance | Requires protective coatings |

| Typical Use | Motors, transformers, high-efficiency applications | Large transformers, cost-sensitive applications |

Introduction: Copper vs Aluminum Winding

Copper winding offers superior electrical conductivity, thermal resistance, and mechanical strength compared to aluminum winding, making it ideal for high-performance electrical motors and generators. Aluminum winding, while lighter and more cost-effective, has lower conductivity and requires larger cross-sections to match copper's efficiency. The choice between copper and aluminum winding significantly impacts the durability, efficiency, and cost-effectiveness of electrical equipment.

Historical Overview of Winding Materials

Copper winding has dominated the electrical industry since the early 20th century due to its superior conductivity and durability, establishing itself as the standard for motor and transformer windings. Aluminum winding emerged as a cost-effective alternative during material shortages and economic shifts in the mid-20th century, offering lighter weight but lower conductivity compared to copper. Advances in alloy technology and insulation materials have gradually improved aluminum winding performance, though copper remains preferred for high-efficiency and high-current applications.

Electrical Conductivity Comparison

Copper winding offers superior electrical conductivity compared to aluminum, with copper having a conductivity of about 59.6 million Siemens per meter (MS/m) while aluminum typically measures around 37.7 MS/m. This higher conductivity in copper results in lower electrical resistance, which enhances efficiency and reduces energy losses in motor or transformer windings. Your choice between copper and aluminum windings will significantly impact performance, especially in applications where energy efficiency and heat dissipation are critical.

Thermal Performance Differences

Copper windings exhibit superior thermal conductivity, approximately 400 W/m*K, compared to aluminum's lower value of about 237 W/m*K, enabling more efficient heat dissipation in electrical machines. This higher thermal performance in copper reduces the risk of overheating and allows for higher current densities, improving reliability and overall efficiency in motors and transformers. Aluminum windings may require larger cross-sectional areas or enhanced cooling methods to match copper's thermal advantages, impacting design constraints and thermal management strategies.

Mechanical Strength and Durability

Copper windings exhibit superior mechanical strength and durability compared to aluminum, making them more resistant to deformation under heavy loads and thermal cycling. Copper's higher tensile strength reduces the risk of wire breakage and fatigue during prolonged operation, enhancing motor and transformer longevity. Aluminum, while lighter and less expensive, is more prone to creep and fracture, which can compromise winding integrity and performance over time.

Cost Analysis: Copper vs Aluminum

Copper winding generally has a higher initial cost compared to aluminum due to copper's superior conductivity and durability, leading to better performance and efficiency in electrical motors and transformers. Aluminum winding offers a cost-effective alternative with lower material expenses but may incur higher losses and potential maintenance costs over time due to its lower conductivity and susceptibility to oxidation. You should consider the trade-off between upfront investment and long-term operational expenses when choosing between copper and aluminum windings.

Weight and Space Considerations

Copper winding offers higher conductivity and requires less cross-sectional area than aluminum, resulting in more compact and lighter electromagnetic components. Aluminum, while lighter by weight, demands larger conductor sizes to achieve equivalent electrical performance, increasing the overall space occupied in winding applications. Engineers often balance copper's superior conductivity with aluminum's weight advantages to optimize design constraints related to weight and spatial efficiency.

Corrosion Resistance and Reliability

Copper windings offer superior corrosion resistance compared to aluminum due to their natural oxide layer that protects against environmental degradation. Aluminum windings are more susceptible to corrosion, especially in humid or saline environments, which can lead to reduced electrical conductivity and reliability issues over time. Copper's enhanced durability results in longer-lasting performance and lower maintenance costs in electrical machines and transformers.

Applications by Industry

Copper winding is preferred in industries requiring high electrical conductivity and durability, such as aerospace, automotive, and power generation sectors, providing efficient performance in motors and transformers. Aluminum winding is commonly used in applications prioritizing cost-effectiveness and weight reduction, like HVAC systems, residential transformers, and some industrial machinery where moderate electrical demands are sufficient. Your choice between copper and aluminum windings should consider industry-specific electrical and mechanical requirements to optimize efficiency and longevity.

Conclusion: Choosing the Right Winding Material

Copper winding offers superior electrical conductivity, higher thermal resistance, and better mechanical strength compared to aluminum winding, making it ideal for high-performance and demanding applications. Aluminum winding provides lighter weight and cost savings but has lower conductivity and durability, which may reduce efficiency and lifespan in certain environments. Selecting the right winding material depends on balancing performance requirements, budget constraints, and the specific operational conditions of the electrical device.

Copper vs Aluminum Winding Infographic

libmatt.com

libmatt.com