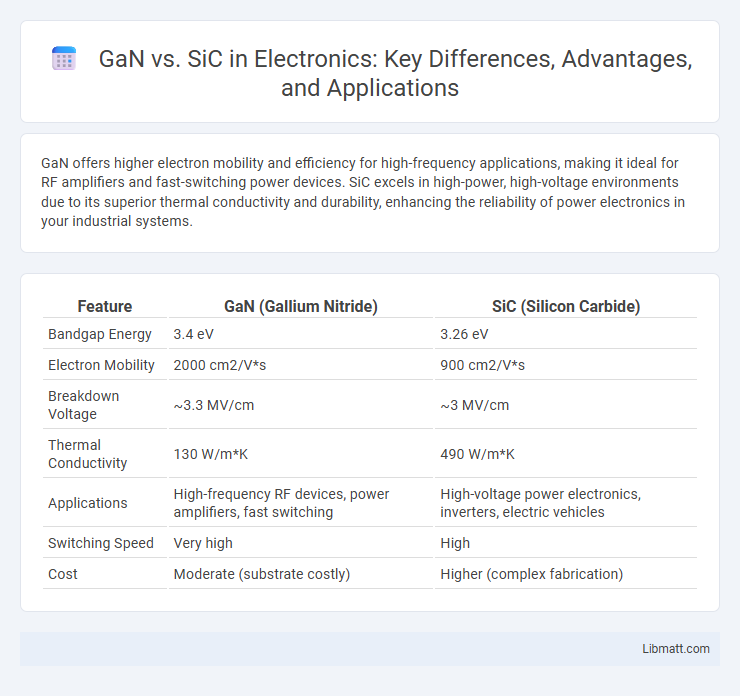

GaN offers higher electron mobility and efficiency for high-frequency applications, making it ideal for RF amplifiers and fast-switching power devices. SiC excels in high-power, high-voltage environments due to its superior thermal conductivity and durability, enhancing the reliability of power electronics in your industrial systems.

Table of Comparison

| Feature | GaN (Gallium Nitride) | SiC (Silicon Carbide) |

|---|---|---|

| Bandgap Energy | 3.4 eV | 3.26 eV |

| Electron Mobility | 2000 cm2/V*s | 900 cm2/V*s |

| Breakdown Voltage | ~3.3 MV/cm | ~3 MV/cm |

| Thermal Conductivity | 130 W/m*K | 490 W/m*K |

| Applications | High-frequency RF devices, power amplifiers, fast switching | High-voltage power electronics, inverters, electric vehicles |

| Switching Speed | Very high | High |

| Cost | Moderate (substrate costly) | Higher (complex fabrication) |

Introduction to GaN and SiC Technologies

Gallium Nitride (GaN) and Silicon Carbide (SiC) are advanced wide-bandgap semiconductor materials enabling higher efficiency and power density in electronic devices compared to traditional silicon. GaN technology excels in high-frequency, high-electron-mobility applications such as RF amplifiers and fast-switching power converters. SiC technology offers superior thermal conductivity and voltage handling, making it ideal for high-power and high-temperature environments like electric vehicles and industrial motor drives.

Material Properties Comparison: GaN vs SiC

Gallium Nitride (GaN) exhibits higher electron mobility and saturation velocity compared to Silicon Carbide (SiC), enabling faster switching speeds and higher frequency performance in power devices. SiC offers superior thermal conductivity and withstands higher electric fields, making it ideal for high-power and high-temperature applications. Your choice between GaN and SiC should consider these intrinsic material properties to optimize efficiency and reliability in specific electronic applications.

Efficiency and Power Performance

Gallium Nitride (GaN) devices offer higher efficiency and faster switching speeds compared to Silicon Carbide (SiC), making them ideal for high-frequency power applications and reducing energy losses. SiC excels in high-voltage and high-temperature environments, providing superior thermal conductivity and robustness for power performance in industrial settings. The choice between GaN and SiC depends on specific efficiency requirements, operating voltage, and thermal conditions in power electronics design.

Thermal Management and Heat Dissipation

Gallium Nitride (GaN) offers superior thermal conductivity of approximately 130 W/m*K compared to Silicon Carbide (SiC) at around 120 W/m*K, enabling more efficient heat dissipation in high-power applications. GaN devices operate at higher junction temperatures, enhancing thermal management by reducing the need for extensive cooling systems. SiC's robust thermal stability supports reliable operation under extreme conditions, but GaN's compact form factor allows for more precise thermal design and improved overall device efficiency.

Switching Speed and Frequency Capabilities

Gallium Nitride (GaN) semiconductors exhibit significantly higher switching speeds compared to Silicon Carbide (SiC), making them ideal for high-frequency applications exceeding 1 MHz. GaN devices achieve lower switching losses and minimal gate charge, enhancing efficiency in RF amplifiers and power converters operating at elevated frequencies. In contrast, SiC devices, while robust at high voltages, typically operate efficiently at lower frequencies due to their slower switching characteristics.

Reliability and Durability Factors

GaN (Gallium Nitride) and SiC (Silicon Carbide) devices both offer exceptional reliability and durability in high-power and high-temperature applications, with SiC excelling in thermal conductivity and robustness under extreme conditions. GaN devices benefit from fast switching speeds and lower on-resistance, which reduce power loss and device stress, enhancing overall system reliability. Your choice depends on the specific operational environment, as SiC's superior avalanche ruggedness suits harsh environments, while GaN's efficiency supports compact, high-performance designs.

Cost Analysis: GaN vs SiC

Gallium Nitride (GaN) devices generally offer lower manufacturing costs compared to Silicon Carbide (SiC) due to simpler fabrication processes and smaller wafer sizes, which reduce material expenses. SiC components typically incur higher initial costs driven by complex crystal growth and processing techniques that impact device pricing in high-power applications. Long-term cost efficiency of GaN is enhanced by its superior switching speeds and efficiency, which can reduce system-level expenses despite SiC's advantages in high-temperature and high-voltage durability.

Applications and Use Cases

Gallium Nitride (GaN) excels in high-frequency and high-efficiency applications such as 5G telecommunications, power amplifiers, and fast chargers due to its superior electron mobility and thermal performance. Silicon Carbide (SiC) is preferred in high-power and high-temperature environments including electric vehicle inverters, industrial motor drives, and renewable energy systems because of its high breakdown voltage and thermal conductivity. Both technologies are revolutionizing power electronics, with GaN dominating high-speed, low-voltage sectors and SiC leading heavy-duty, high-voltage applications.

Market Trends and Industry Adoption

GaN (Gallium Nitride) and SiC (Silicon Carbide) are rapidly gaining traction in power electronics, with GaN leading in high-frequency applications like fast chargers and RF components due to its superior electron mobility and efficiency. SiC is favored in high-power, high-temperature environments such as electric vehicles and renewable energy systems, benefiting from its robust thermal conductivity and high breakdown voltage. Your choice between GaN and SiC will depend on specific application requirements, with the market increasingly adopting both technologies to optimize performance and energy efficiency.

Future Prospects of GaN and SiC

GaN (Gallium Nitride) and SiC (Silicon Carbide) both offer transformative potential for power electronics, with GaN excelling in high-frequency applications and SiC dominating high-voltage and high-temperature environments. Their future prospects include broad adoption in electric vehicles, renewable energy systems, and 5G infrastructure due to their superior efficiency and thermal performance compared to traditional silicon devices. Investing in GaN and SiC technology development can significantly enhance your power system's performance and energy savings.

GaN vs SiC Infographic

libmatt.com

libmatt.com