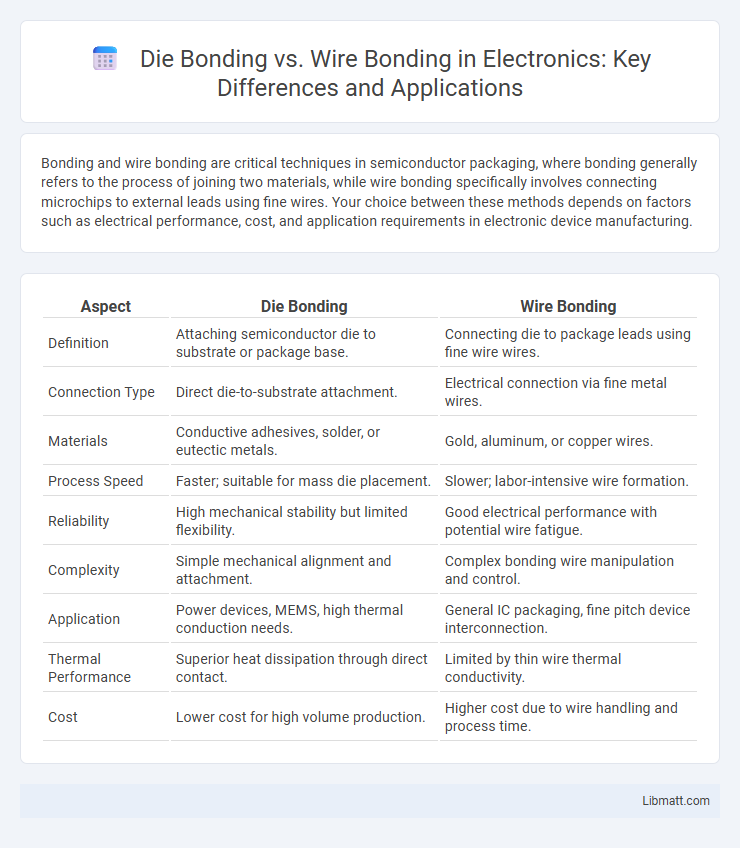

Bonding and wire bonding are critical techniques in semiconductor packaging, where bonding generally refers to the process of joining two materials, while wire bonding specifically involves connecting microchips to external leads using fine wires. Your choice between these methods depends on factors such as electrical performance, cost, and application requirements in electronic device manufacturing.

Table of Comparison

| Aspect | Die Bonding | Wire Bonding |

|---|---|---|

| Definition | Attaching semiconductor die to substrate or package base. | Connecting die to package leads using fine wire wires. |

| Connection Type | Direct die-to-substrate attachment. | Electrical connection via fine metal wires. |

| Materials | Conductive adhesives, solder, or eutectic metals. | Gold, aluminum, or copper wires. |

| Process Speed | Faster; suitable for mass die placement. | Slower; labor-intensive wire formation. |

| Reliability | High mechanical stability but limited flexibility. | Good electrical performance with potential wire fatigue. |

| Complexity | Simple mechanical alignment and attachment. | Complex bonding wire manipulation and control. |

| Application | Power devices, MEMS, high thermal conduction needs. | General IC packaging, fine pitch device interconnection. |

| Thermal Performance | Superior heat dissipation through direct contact. | Limited by thin wire thermal conductivity. |

| Cost | Lower cost for high volume production. | Higher cost due to wire handling and process time. |

Introduction to Die Bonding and Wire Bonding

Die bonding and wire bonding are essential semiconductor packaging techniques used to establish electrical connections between the silicon die and the package substrate. Die bonding involves attaching the semiconductor chip directly onto the substrate or lead frame using conductive or adhesive materials, ensuring mechanical stability and thermal conductivity. Wire bonding uses fine metal wires, typically gold or aluminum, to connect bond pads on the die to the substrate, providing flexible electrical interconnections vital for your device's performance.

Understanding the Role in Microelectronics Packaging

Die bonding and wire bonding are critical processes in microelectronics packaging, ensuring electrical connectivity and mechanical stability between semiconductor dies and substrates. Die bonding secures the semiconductor chip onto the package or PCB using adhesives or solder, optimizing thermal conductivity and mechanical reliability. Wire bonding connects the bonded die to external leads with fine wires, typically gold or aluminum, forming the essential electrical pathways for chip functionality.

Die Bonding: Process Overview

Die bonding is a critical step in semiconductor packaging where the semiconductor die is precisely attached to a substrate or package using conductive or non-conductive adhesives, solder, or eutectic materials. This process ensures mechanical stability and optimal thermal and electrical connections by carefully controlling parameters such as temperature, pressure, and alignment. Your device's overall performance and reliability heavily depend on the accuracy and quality of the die bonding process.

Wire Bonding: Process Overview

Wire bonding involves connecting semiconductor devices to their package leads using fine metal wires, typically made of gold, aluminum, or copper. The process includes placing the die on a substrate, then using ultrasonic, thermosonic, or thermocompression bonding techniques to attach wires from the die's bond pads to the lead frame. This method is widely used for its cost-effectiveness, reliability, and suitability for high-volume microelectronic packaging.

Key Differences Between Die Bonding and Wire Bonding

Die bonding involves attaching semiconductor chips directly onto substrates using conductive adhesives or solder, ensuring strong mechanical and thermal connections. Wire bonding connects the die to the package leads through fine metal wires, enabling electrical signal transmission but with added inductance and potential reliability concerns. Your choice between die bonding and wire bonding impacts manufacturing precision, electrical performance, and packaging cost.

Materials and Equipment Used in Each Method

Die bonding uses conductive adhesives or solder alloys to attach semiconductor chips directly onto substrates, requiring precision die bonders equipped with vacuum pick-up tools. Wire bonding employs fine gold, aluminum, or copper wires to connect the die pads to package leads, utilizing ultrasonic or thermosonic bonding machines designed for high accuracy and repeatability. Understanding the materials and specialized equipment in each method helps optimize Your semiconductor assembly process for reliability and cost-efficiency.

Performance and Reliability Comparison

Die bonding offers superior thermal management and electrical performance by providing a shorter signal path and enhanced heat dissipation compared to wire bonding, which relies on thin metal wires that can introduce higher parasitic inductance and resistance. Wire bonding remains popular due to its cost-effectiveness and flexibility for various package types, but it can exhibit lower reliability in high-vibration or high-temperature environments due to wire fatigue and breakage. Overall, die bonding excels in high-performance applications requiring robust thermal and electrical integrity, while wire bonding is suitable for less demanding, cost-sensitive uses.

Typical Applications and Industry Uses

Die bonding is commonly used in high-frequency and power semiconductor devices, enabling superior thermal management ideal for automotive, aerospace, and LED lighting industries. Wire bonding remains prevalent in consumer electronics, sensors, and medical devices due to its cost-effectiveness and flexibility in connecting integrated circuits to external leads. Your choice depends on application requirements such as performance, reliability, and manufacturing volume.

Advantages and Limitations of Each Technique

Die bonding offers superior mechanical stability and high thermal conductivity, making it ideal for applications requiring robust heat dissipation and precise alignment. Wire bonding excels in cost-effectiveness and flexibility, supporting fine-pitch connections and complex circuit designs, but it may suffer from limited current-carrying capacity and vulnerability to mechanical stress. Both techniques present trade-offs: die bonding demands higher initial setup and processing costs, while wire bonding is prone to wire breakage and reliability issues under harsh environmental conditions.

Future Trends in Semiconductor Bonding Technologies

Future trends in semiconductor bonding technologies emphasize advanced die bonding techniques that enhance thermal management and electrical performance in high-density packaging. Innovations like hybrid bonding and fan-out wafer-level packaging are predicted to surpass traditional wire bonding by offering improved miniaturization and reliability for next-generation devices. Your semiconductor manufacturing processes will benefit from these developments through increased efficiency and scalability in complex integrated circuits.

Die Bonding vs Wire Bonding Infographic

libmatt.com

libmatt.com