DIP switches are ideal for setting multiple configurations on circuit boards, offering reliable binary control through a series of small toggle switches, while tactile switches provide momentary, user-friendly feedback with a distinct click sensation, perfect for manual inputs. Your choice depends on whether you need persistent settings or responsive, tactile interaction in your electronic device.

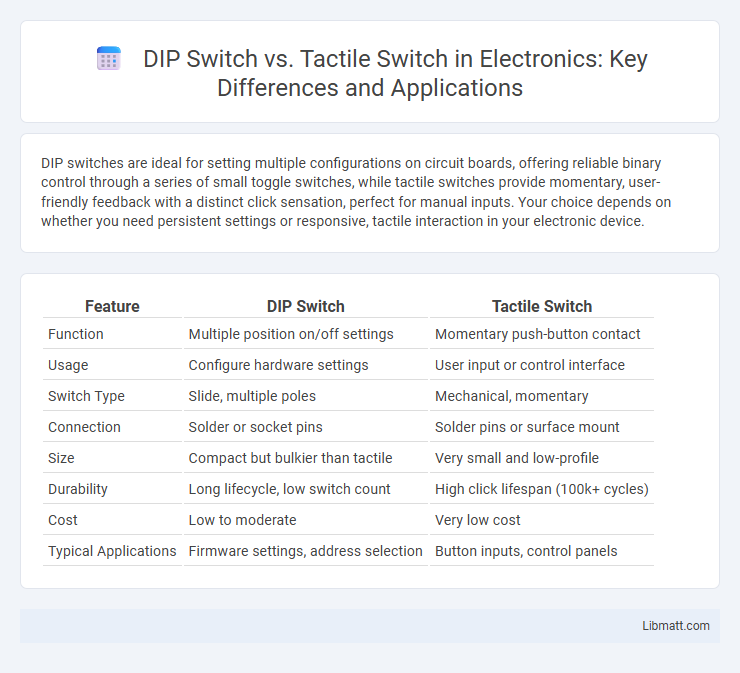

Table of Comparison

| Feature | DIP Switch | Tactile Switch |

|---|---|---|

| Function | Multiple position on/off settings | Momentary push-button contact |

| Usage | Configure hardware settings | User input or control interface |

| Switch Type | Slide, multiple poles | Mechanical, momentary |

| Connection | Solder or socket pins | Solder pins or surface mount |

| Size | Compact but bulkier than tactile | Very small and low-profile |

| Durability | Long lifecycle, low switch count | High click lifespan (100k+ cycles) |

| Cost | Low to moderate | Very low cost |

| Typical Applications | Firmware settings, address selection | Button inputs, control panels |

Understanding DIP Switches: Overview and Applications

DIP switches are compact, manual electric switches that allow for binary input settings, commonly used in configuring hardware options on circuit boards or devices. These switches offer reliable, low-cost customization for settings such as device addresses, mode selection, and feature toggling, making them prevalent in consumer electronics and industrial equipment. Your understanding of DIP switches can enhance troubleshooting and customization tasks by providing precise control over hardware configurations without software intervention.

Exploring Tactile Switches: Features and Uses

Tactile switches provide precise, momentary contact with a noticeable click feedback, ideal for user interfaces in electronic devices. Their compact design supports easy integration into PCBs, making them suitable for keyboards, remote controls, and gaming controllers. You can choose tactile switches for applications requiring reliable, responsive input with a satisfying tactile feel.

Key Differences Between DIP Switches and Tactile Switches

DIP switches are small manual electronic switches used to configure settings on a circuit board, offering multiple switch positions for binary options, while tactile switches provide momentary, single-action input with a noticeable "click" feedback. Your application dictates the choice: DIP switches excel in setting configurations requiring multiple on/off states without power, whereas tactile switches are ideal for user interfaces needing immediate, temporary input. The key difference lies in DIP switches maintaining stable positions, while tactile switches reset after each press.

How DIP Switches Work: Mechanism and Configuration

DIP switches operate through a series of small manual toggles mounted on a dual in-line package, allowing users to set binary configurations by flipping individual switches on or off. Each switch acts as an isolated electrical contact, completing or breaking a circuit when toggled, enabling customized device settings without soldering or programming. Your ability to easily configure multi-bit inputs makes DIP switches a preferred choice for static, hardware-level adjustments in electronics.

The Functionality of Tactile Switches: Operation and Types

Tactile switches function by providing a physical feedback mechanism through a small, spring-loaded button that completes an electrical circuit when pressed, commonly used in keyboards and electronic control panels. They operate primarily in momentary or push-to-make modes, with variations including surface-mount and through-hole designs tailored for different PCB applications. Popular types include tactile push buttons, dome switches, and micro switches, each offering distinct actuation force and travel distance to suit various user interface requirements.

DIP Switch vs Tactile Switch: Pros and Cons

DIP switches offer reliable multi-position settings with easy configuration and durability, making them ideal for setting device parameters without complex software. Tactile switches provide a compact design with a satisfying click feedback, suitable for user input in compact electronics, but can wear out with heavy use and lack multi-position functionality. Your choice depends on whether you need configurable hardware settings with long-term stability (DIP switch) or responsive, space-saving button inputs (tactile switch).

Common Applications in Electronics: DIP vs Tactile Switch

DIP switches are widely used in electronic devices for setting configurations and addressing, such as in motherboards, remote controls, and industrial equipment, offering reliable binary input selection. Tactile switches are commonly found in consumer electronics including keyboards, calculators, and control panels, providing tactile feedback for user interface inputs. Your choice depends on whether you need preset configurations (DIP) or momentary, user-activated inputs (tactile).

Selection Criteria: Choosing the Right Switch for Your Project

Selecting the right switch for your project depends on factors such as functionality, durability, and user interaction. DIP switches offer reliable, low-profile options for customizing circuit configurations with multiple toggle positions, making them ideal for settings requiring binary input and system configurations. Tactile switches provide responsive, momentary contact for user interfaces needing feedback and quick activation, suitable for control panels and consumer electronics where user experience is critical.

Installation and Maintenance: DIP Switch vs Tactile Switch

DIP switches are designed for straightforward PCB installation, requiring soldering that ensures a stable and durable connection, while tactile switches often come in surface-mount or through-hole versions demanding precise placement to maintain functionality. Maintenance of DIP switches is minimal due to their robust design but may involve careful cleaning to avoid contact oxidation in industrial environments, whereas tactile switches, subjected to frequent mechanical actuation, may require more frequent replacement or inspection to prevent failure from wear. Both types benefit from proper installation torque and environment control to extend operational lifespan and reliability.

Future Trends in Switch Technology: What’s Next?

Emerging trends in switch technology highlight the integration of smart features and IoT compatibility, pushing DIP switches to evolve towards digital configurations with programmable options. Tactile switches are advancing with enhanced durability, haptic feedback innovations, and miniaturization to support wearable and flexible electronics. Your choice between DIP and tactile switches will depend on the balance between legacy control needs and the demand for interactive, responsive interfaces in future devices.

DIP Switch vs Tactile Switch Infographic

libmatt.com

libmatt.com