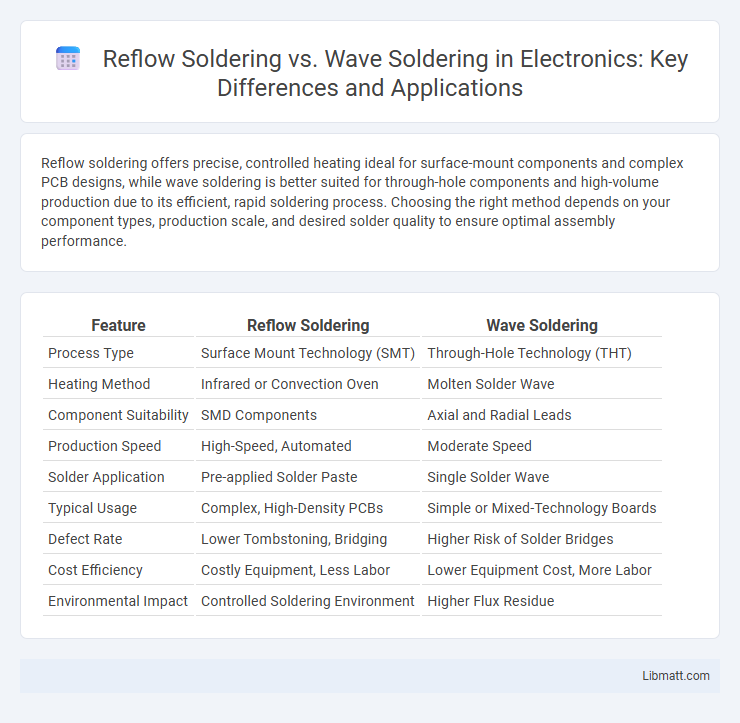

Reflow soldering offers precise, controlled heating ideal for surface-mount components and complex PCB designs, while wave soldering is better suited for through-hole components and high-volume production due to its efficient, rapid soldering process. Choosing the right method depends on your component types, production scale, and desired solder quality to ensure optimal assembly performance.

Table of Comparison

| Feature | Reflow Soldering | Wave Soldering |

|---|---|---|

| Process Type | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

| Heating Method | Infrared or Convection Oven | Molten Solder Wave |

| Component Suitability | SMD Components | Axial and Radial Leads |

| Production Speed | High-Speed, Automated | Moderate Speed |

| Solder Application | Pre-applied Solder Paste | Single Solder Wave |

| Typical Usage | Complex, High-Density PCBs | Simple or Mixed-Technology Boards |

| Defect Rate | Lower Tombstoning, Bridging | Higher Risk of Solder Bridges |

| Cost Efficiency | Costly Equipment, Less Labor | Lower Equipment Cost, More Labor |

| Environmental Impact | Controlled Soldering Environment | Higher Flux Residue |

Introduction to Reflow and Wave Soldering

Reflow soldering uses a controlled oven to melt solder paste, bonding surface-mount components to PCBs with precise temperature profiles. Wave soldering involves passing PCBs over a molten solder wave to attach through-hole components, enabling efficient mass production. Both techniques are essential in electronics manufacturing, selected based on component type and assembly requirements.

Overview of Reflow Soldering Process

Reflow soldering involves applying solder paste to PCB pads, placing components, and then passing the board through a controlled heating oven where the solder paste melts and solidifies, creating strong electrical connections. Precise temperature profiles ensure solder joints are reliable without damaging sensitive components. This process is ideal for surface-mount technology (SMT), making it essential for modern electronics manufacturing.

Overview of Wave Soldering Process

Wave soldering involves passing a printed circuit board (PCB) over a wave of molten solder, ensuring simultaneous soldering of multiple component leads to the board. This process is highly effective for through-hole components and provides strong mechanical and electrical connections. Your manufacturing efficiency benefits from wave soldering's rapid throughput and consistent solder joints on large production runs.

Key Equipment and Materials Used

Reflow soldering utilizes a reflow oven, solder paste, and stencil printer to apply and heat solder paste onto surface mount components, ensuring precise temperature profiles for optimal solder joint formation. Wave soldering employs a wave solder machine, solder pot with molten solder, and flux application systems to solder through-hole components by passing the PCB over a continuous solder wave. Both methods rely on flux types compatible with their processes and require precise control of solder temperature and conveyor speed for consistent, reliable joints.

Process Differences: Reflow vs Wave Soldering

Reflow soldering involves applying solder paste on PCB pads, placing components, and then heating the assembly in a controlled infrared or convection oven to melt the solder and create electrical connections. Wave soldering uses a flowing wave of molten solder to simultaneously solder all components on the underside of a PCB, typically for through-hole or mixed technology assemblies. The primary process difference lies in reflow soldering's precise temperature profiles for surface-mounted devices versus wave soldering's continuous molten solder wave for mass soldering of through-hole components.

Applications and Suitability for PCB Assembly

Reflow soldering is ideal for surface mount technology (SMT) components on printed circuit boards (PCBs), offering precise heat control that ensures reliable solder joints for complex and densely populated assemblies. Wave soldering excels in through-hole technology (THT) applications and is suited for medium to high-volume production, providing efficient soldering of entire boards with mixed SMT and THT components. Selecting between reflow and wave soldering depends on component type, board design, and production scale, impacting assembly quality and manufacturing efficiency.

Advantages of Reflow Soldering

Reflow soldering offers precise control over temperature profiles, ensuring consistent and high-quality solder joints for surface mount technology (SMT) components. This method minimizes thermal stress on delicate components, enhancing reliability and reducing the risk of damage compared to wave soldering. Your production process benefits from greater flexibility and adaptability to various PCB designs, including fine-pitch components, making reflow soldering ideal for modern electronic assemblies.

Advantages of Wave Soldering

Wave soldering offers advantages such as high throughput for through-hole components and consistent solder joints on complex PCB assemblies. It provides excellent soldering quality with minimal bridging and reliable mechanical strength, ideal for mass production. Your manufacturing process benefits from lower operational costs due to reduced manual labor and faster cycle times.

Common Defects and Quality Considerations

Reflow soldering commonly faces defects such as solder bridging, tombstoning, and insufficient wetting, which impact connection reliability and require precise temperature profiling for quality control. Wave soldering defects often include solder balls, bridging, and cold joints due to improper conveyor speed or wave height, affecting overall joint integrity. Understanding these common defects helps optimize Your soldering process, ensuring consistent PCB assembly quality and minimizing rework costs.

Choosing the Right Soldering Method for Your Project

Selecting the appropriate soldering method depends on your project's complexity, component types, and production volume. Reflow soldering excels in handling surface-mount devices (SMD) with precision, making it ideal for intricate printed circuit boards (PCBs) and high-density assemblies. Wave soldering suits through-hole components and larger batches, offering cost-effective, efficient soldering for simpler designs and bulk manufacturing.

Reflow Soldering vs Wave Soldering Infographic

libmatt.com

libmatt.com