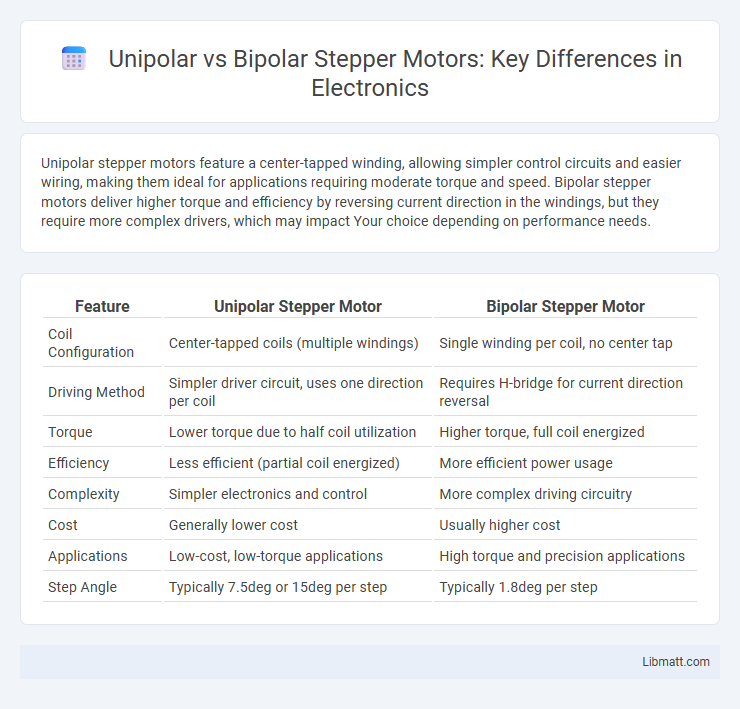

Unipolar stepper motors feature a center-tapped winding, allowing simpler control circuits and easier wiring, making them ideal for applications requiring moderate torque and speed. Bipolar stepper motors deliver higher torque and efficiency by reversing current direction in the windings, but they require more complex drivers, which may impact Your choice depending on performance needs.

Table of Comparison

| Feature | Unipolar Stepper Motor | Bipolar Stepper Motor |

|---|---|---|

| Coil Configuration | Center-tapped coils (multiple windings) | Single winding per coil, no center tap |

| Driving Method | Simpler driver circuit, uses one direction per coil | Requires H-bridge for current direction reversal |

| Torque | Lower torque due to half coil utilization | Higher torque, full coil energized |

| Efficiency | Less efficient (partial coil energized) | More efficient power usage |

| Complexity | Simpler electronics and control | More complex driving circuitry |

| Cost | Generally lower cost | Usually higher cost |

| Applications | Low-cost, low-torque applications | High torque and precision applications |

| Step Angle | Typically 7.5deg or 15deg per step | Typically 1.8deg per step |

Introduction to Stepper Motors

Stepper motors convert electrical pulses into precise mechanical movements, enabling accurate position control for applications like 3D printers and CNC machines. Unipolar stepper motors feature a center-tapped winding design allowing simpler driving circuits with multiple coils energized in sequence, offering easier control but lower torque. Bipolar stepper motors use a single winding per phase requiring H-bridge drivers to reverse current, delivering higher torque and efficiency suitable for demanding motion control tasks.

What is a Unipolar Stepper Motor?

A unipolar stepper motor features a center-tapped winding on each phase, allowing current to flow through one half of the coil at a time, which simplifies driver circuitry and enables easier control. It typically has five or six wires, where the center tap serves as a common return path for each winding, enhancing torque at lower speeds but resulting in less torque overall compared to bipolar motors. This design is ideal for applications requiring simpler control and moderate precision without the need for high torque performance.

What is a Bipolar Stepper Motor?

A Bipolar Stepper Motor is a type of stepper motor that uses two coils with a single winding per phase and requires current to flow in both directions through each coil to achieve precise control. It provides higher torque compared to unipolar stepper motors due to the full utilization of the coil windings. Understanding your choice between bipolar and unipolar stepper motors is crucial for optimizing performance in applications like robotics and CNC machines.

Key Differences between Unipolar and Bipolar Steppers

Unipolar stepper motors feature a center-tapped winding allowing simpler driving circuits and easier control, making them ideal for applications requiring moderate torque and speed. Bipolar stepper motors use a single winding per phase with current reversals for higher torque and efficiency, suitable for more demanding precision tasks. Your choice between unipolar and bipolar steppers depends on power requirements, control complexity, and desired motor performance.

Wiring and Circuit Complexity

Unipolar stepper motors feature simpler wiring with five or six leads, enabling easier connection and control through a single winding center tap, which reduces circuit complexity. Bipolar stepper motors require four leads and lack center taps, demanding an H-bridge driver for current reversal, resulting in more complex circuitry but higher torque output. The choice between unipolar and bipolar stepper motors significantly impacts the design and cost of the driver electronics in precision motion control applications.

Performance and Torque Comparison

Bipolar stepper motors generally deliver higher torque and better performance than unipolar steppers due to their ability to utilize the entire coil winding, resulting in stronger magnetic fields. Unipolar stepper motors have simpler drive electronics but typically produce less torque, making them suitable for applications with lower power requirements. Your choice between unipolar and bipolar stepper motors should consider the need for torque intensity and precision in movement for optimal results.

Control Mechanisms and Driving Methods

Unipolar stepper motors use center-tapped windings allowing simpler control through switching individual coils, enabling easy implementation with single transistor drivers and facilitating straightforward current direction reversal. Bipolar stepper motors require full H-bridge circuits to reverse current through each winding, offering higher torque due to full coil utilization but demanding more complex control electronics. The driving methods differ significantly, with unipolar motors controlled via simpler switching approaches and bipolar motors relying on more advanced pulse width modulation (PWM) techniques for precise current regulation and efficient performance.

Common Applications for Each Type

Unipolar stepper motors are commonly used in applications requiring simpler control and moderate torque, such as 3D printers, small CNC machines, and office automation equipment. Bipolar stepper motors provide higher torque and efficiency, making them ideal for robotics, industrial automation, and automotive systems. Your choice depends on the required torque, complexity, and precision of the application.

Pros and Cons: Unipolar vs Bipolar Stepper Motors

Unipolar stepper motors offer simpler control circuits and ease of use due to their center-tapped windings, making them suitable for applications requiring moderate torque and speed. Bipolar stepper motors provide higher torque and efficiency because current flows through the entire winding, but they require more complex drivers like H-bridges. Your choice depends on the specific needs of your project, balancing ease of control with performance requirements.

Choosing the Right Stepper Motor for Your Project

Selecting the right stepper motor depends on torque requirements, wiring complexity, and control methods; unipolar stepper motors offer simpler wiring and ease of use, making them ideal for low to moderate torque applications. Bipolar stepper motors, with higher torque output and more efficient power utilization, suit projects demanding precise motion control and greater mechanical load capacity. Evaluate factors such as current consumption, driver compatibility, and performance needs to determine the optimal choice between unipolar and bipolar stepper motors for your specific application.

Unipolar Stepper vs Bipolar Stepper Infographic

libmatt.com

libmatt.com