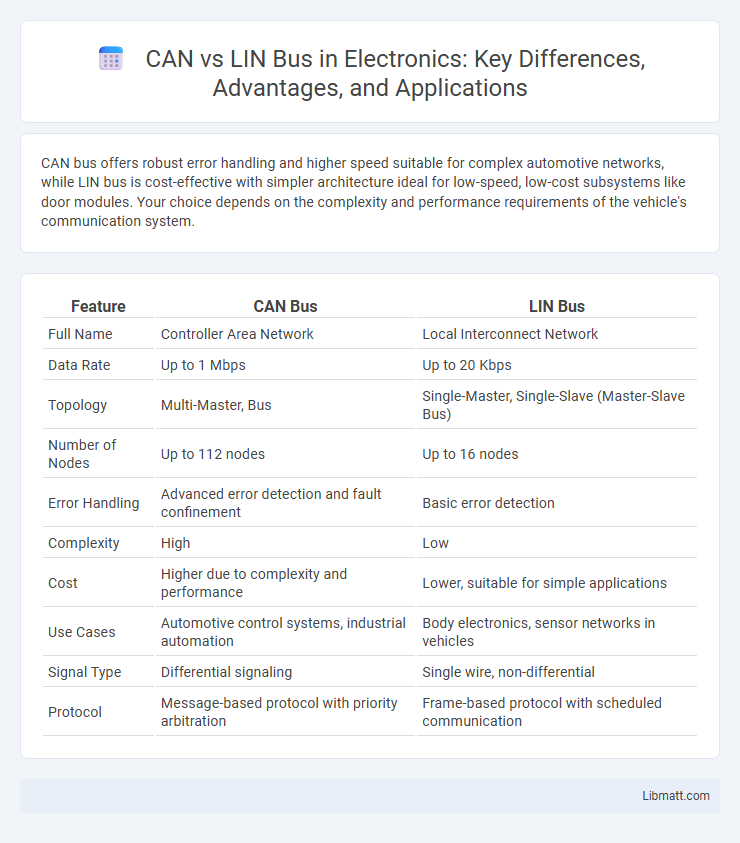

CAN bus offers robust error handling and higher speed suitable for complex automotive networks, while LIN bus is cost-effective with simpler architecture ideal for low-speed, low-cost subsystems like door modules. Your choice depends on the complexity and performance requirements of the vehicle's communication system.

Table of Comparison

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Full Name | Controller Area Network | Local Interconnect Network |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Topology | Multi-Master, Bus | Single-Master, Single-Slave (Master-Slave Bus) |

| Number of Nodes | Up to 112 nodes | Up to 16 nodes |

| Error Handling | Advanced error detection and fault confinement | Basic error detection |

| Complexity | High | Low |

| Cost | Higher due to complexity and performance | Lower, suitable for simple applications |

| Use Cases | Automotive control systems, industrial automation | Body electronics, sensor networks in vehicles |

| Signal Type | Differential signaling | Single wire, non-differential |

| Protocol | Message-based protocol with priority arbitration | Frame-based protocol with scheduled communication |

Introduction to CAN and LIN Bus Systems

CAN bus systems enable robust communication in automotive and industrial applications using a multi-master, message-oriented protocol with high fault tolerance and speeds up to 1 Mbps. LIN bus offers a cost-effective, single-master, serial communication solution for lower-speed (up to 20 Kbps) in-vehicle networks, typically controlling simpler devices like switches and sensors. Your choice between CAN and LIN depends on the required network complexity, data speed, and fault tolerance for efficient system integration.

Key Differences Between CAN and LIN

CAN (Controller Area Network) offers high-speed communication up to 1 Mbps with robust error detection and multi-master arbitration, making it ideal for complex automotive systems. LIN (Local Interconnect Network) provides low-speed communication around 20 Kbps, with simpler, single-master topology designed for cost-effective control of non-critical subsystems like window regulators and seat controllers. CAN supports real-time data exchange with higher reliability, whereas LIN is best suited for less demanding applications requiring minimal wiring and lower implementation costs.

Architecture and Communication Protocols

CAN bus utilizes a multi-master, message-oriented protocol with priority-based arbitration for real-time communication, enabling robust error detection and fault confinement. LIN bus operates as a single-master, multiple-slave configuration with a time-triggered, master-slave communication protocol designed for low-cost, low-speed networking. CAN supports higher data rates up to 1 Mbps with complex message framing, while LIN is limited to 20 Kbps and employs simpler, fixed-length frames for less critical applications.

Data Transmission Speeds and Reliability

CAN bus supports data transmission speeds up to 1 Mbps, providing high reliability through error detection and fault confinement mechanisms, making it ideal for critical automotive systems. LIN bus operates at a lower speed, typically up to 20 Kbps, and offers simpler, cost-effective communication primarily for non-critical body control functions. Your choice between CAN and LIN bus depends on the required speed and reliability for your vehicle's network architecture.

Typical Applications of CAN Bus

CAN bus is widely used in automotive systems for real-time control of engine management, transmission, and anti-lock braking systems due to its high-speed data transfer and robustness against electrical interference. Industrial automation and manufacturing equipment also rely on CAN bus for reliable communication between sensors, actuators, and controllers in harsh environments. Your ability to integrate CAN bus ensures seamless coordination in complex systems where safety and precision are critical.

Typical Applications of LIN Bus

LIN bus is typically used in automotive body control applications such as door modules, seat control, and climate control systems where low-cost and simplicity are critical. It is ideal for connecting sensors and actuators in non-critical communication networks within vehicles. LIN bus complements CAN bus by handling less complex tasks, allowing CAN to manage more demanding real-time control functions.

Network Topology and Scalability

CAN bus utilizes a multi-master, broadcast network topology allowing multiple nodes to communicate over a single twisted-pair cable, enhancing scalability for complex automotive and industrial systems. LIN bus employs a single-master, multiple-slave topology with a simple serial connection, limiting scalability but reducing cost for lower-speed applications and smaller networks. The CAN network supports larger node counts and more flexible expansion, whereas LIN is optimized for simpler, point-to-point or low-node-count configurations.

Cost and Implementation Considerations

CAN bus systems typically have higher initial costs due to more complex hardware and robust error-handling features, making them suitable for critical automotive and industrial applications. LIN bus offers a lower-cost alternative with simpler implementation, relying on a single-wire design ideal for non-critical components like sensors and actuators. The choice between CAN and LIN depends on system requirements, with CAN favored for high-speed, reliable communication and LIN for cost-efficient, low-speed control networks.

Integration and Compatibility in Automotive Design

CAN bus offers broad integration capabilities with numerous automotive subsystems due to its standardized protocol and high data rate, making it ideal for complex vehicle networks. LIN bus provides cost-effective compatibility for simpler, localized components like door modules and climate control where low-speed communication suffices. Your automotive design benefits from combining CAN's robustness with LIN's simplicity to optimize overall system integration and maintain seamless interoperability.

Future Trends: CAN, LIN, and Emerging Technologies

Future trends in automotive networking show CAN bus evolving with CAN FD, enabling higher data rates up to 8 Mbps, enhancing performance for autonomous and electric vehicles. LIN bus remains vital for low-cost, simple control systems but faces integration with Ethernet for increased bandwidth demands. Emerging technologies like Automotive Ethernet and FlexRay complement CAN and LIN, driving seamless communication across complex vehicle architectures and supporting advanced driver-assistance systems (ADAS).

CAN vs LIN bus Infographic

libmatt.com

libmatt.com