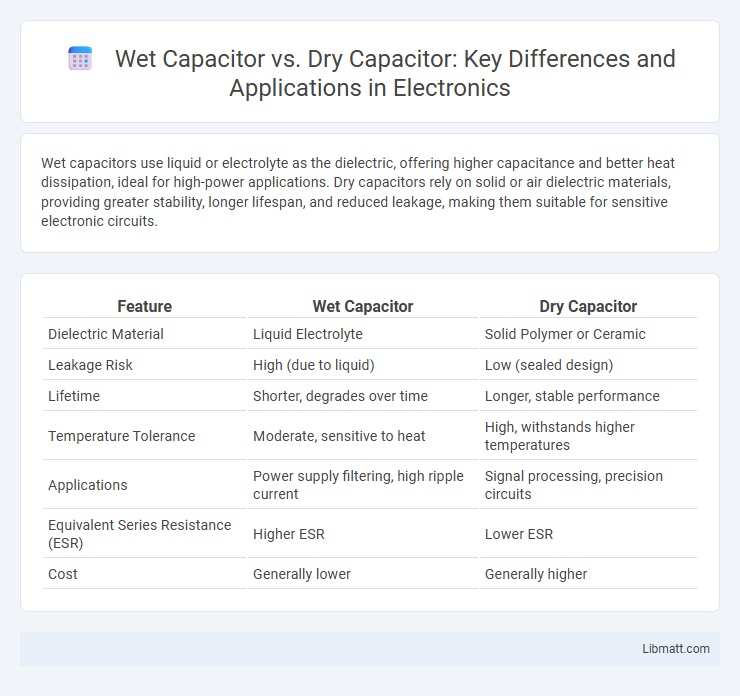

Wet capacitors use liquid or electrolyte as the dielectric, offering higher capacitance and better heat dissipation, ideal for high-power applications. Dry capacitors rely on solid or air dielectric materials, providing greater stability, longer lifespan, and reduced leakage, making them suitable for sensitive electronic circuits.

Table of Comparison

| Feature | Wet Capacitor | Dry Capacitor |

|---|---|---|

| Dielectric Material | Liquid Electrolyte | Solid Polymer or Ceramic |

| Leakage Risk | High (due to liquid) | Low (sealed design) |

| Lifetime | Shorter, degrades over time | Longer, stable performance |

| Temperature Tolerance | Moderate, sensitive to heat | High, withstands higher temperatures |

| Applications | Power supply filtering, high ripple current | Signal processing, precision circuits |

| Equivalent Series Resistance (ESR) | Higher ESR | Lower ESR |

| Cost | Generally lower | Generally higher |

Introduction to Wet and Dry Capacitors

Wet capacitors use a liquid electrolyte to enhance dielectric properties and cooling, improving performance in high-voltage and high-frequency applications. Dry capacitors utilize solid or paper dielectric materials without liquid, offering greater reliability, longer life expectancy, and reduced maintenance in power systems. The choice between wet and dry capacitors depends on factors like voltage rating, environmental conditions, and operational requirements in electrical and electronic circuits.

Understanding Capacitor Technology

Wet capacitors contain liquid electrolytes that enable higher capacitance and better cooling, making them ideal for high-power applications. Dry capacitors, filled with solid dielectric materials such as ceramic or plastic film, offer greater reliability and long-term stability with minimal maintenance. Understanding the differences in dielectric medium helps you select the right capacitor technology for your specific electrical and environmental needs.

Construction Differences: Wet vs Dry

Wet capacitors contain a liquid dielectric, often oil or electrolyte, enabling higher capacitance and self-healing properties, whereas dry capacitors use solid dielectrics such as ceramic, polyester, or mica for insulation. The sealing in wet capacitors is more complex to prevent leaks, while dry capacitors are sealed with epoxy or resin, ensuring stability and compactness. Construction differences directly impact performance metrics like voltage rating, lifespan, and suitability for high-frequency or high-voltage applications.

Key Applications of Wet Capacitors

Wet capacitors are commonly used in high-voltage and power transmission applications due to their superior ability to handle high ripple currents and better thermal stability. Their liquid dielectric makes them ideal for industrial motor run capacitors, power factor correction devices, and high-power electrical equipment where consistent performance under heavy load is crucial. Your choice of wet capacitors ensures enhanced reliability and longevity in demanding electrical systems.

Typical Uses of Dry Capacitors

Dry capacitors are commonly used in applications where reliability and low maintenance are critical, such as in power supplies, signal processing, and electronic circuits requiring stable performance under varying environmental conditions. These capacitors excel in environments with low moisture exposure, making them ideal for consumer electronics, automotive electronics, and industrial control systems. Their solid dielectric materials ensure minimal leakage current and longer lifespan compared to wet capacitors in these typical uses.

Performance Comparison: Wet vs Dry

Wet capacitors offer higher capacitance stability and better tolerance to voltage spikes, making them ideal for heavy-duty industrial applications. Dry capacitors, while providing lower capacitance values, excel in reliability and have a longer lifespan due to their solid dielectric materials, which minimize leakage and maintenance. Your choice depends on performance needs: wet capacitors prioritize robustness under load, while dry capacitors deliver consistent, maintenance-free operation.

Lifespan and Reliability Factors

Wet capacitors generally exhibit longer lifespan and higher reliability due to their liquid dielectric, which efficiently dissipates heat and reduces the risk of dielectric breakdown. Dry capacitors, while more compact and less prone to leakage, tend to have shorter operational life under high temperature or voltage stress because their solid dielectric materials degrade faster. Reliability factors such as operating temperature, voltage rating, and maintenance conditions critically influence the longevity of both wet and dry capacitors.

Cost Considerations and Availability

Wet capacitors typically incur higher costs due to their oil-filled design and more complex manufacturing process, making them less accessible for low-budget applications. Dry capacitors, leveraging solid dielectrics, offer a more cost-effective and widely available option across various voltage and capacitance ratings. Availability of dry capacitors spans mass production and diverse suppliers, while wet capacitors are more specialized, limiting market options and driving up purchase prices.

Advantages and Disadvantages

Wet capacitors offer superior cooling and higher voltage handling capabilities due to their liquid electrolyte, making them ideal for high-power applications. However, they require regular maintenance to prevent leakage and have a shorter lifespan compared to dry capacitors, which are more compact, maintenance-free, and safer for typical consumer electronics. Your choice depends on balancing the need for durability and performance against maintenance and safety considerations.

How to Choose the Right Capacitor Type

Selecting the right capacitor type depends on your circuit's application and environmental conditions; wet capacitors, filled with electrolyte, offer higher capacitance and better performance under high load but may leak and have a shorter lifespan. Dry capacitors, devoid of liquid electrolyte, provide greater stability, longer service life, and improved safety for sensitive or high-frequency electronic devices. Consider your device's operating temperature, voltage requirements, and space constraints to ensure Your system's efficiency and reliability when choosing between wet and dry capacitors.

Wet Capacitor vs Dry Capacitor Infographic

libmatt.com

libmatt.com