Soft start technology gradually increases the electrical current to your motor, reducing mechanical stress and extending equipment lifespan, while hard start methods apply full current immediately, which can cause more wear and sudden power surges. Choosing soft start helps improve energy efficiency and minimize maintenance costs in the long run.

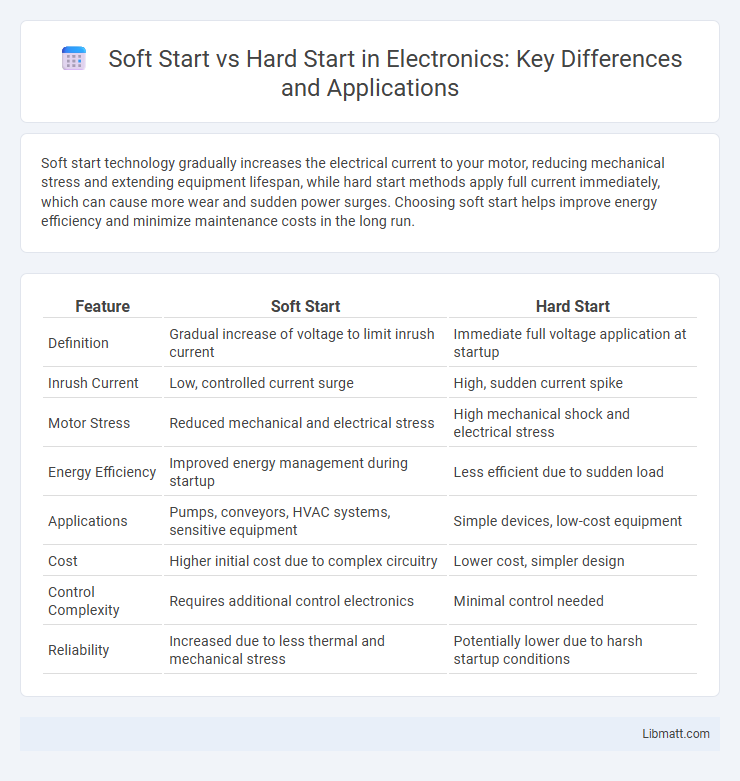

Table of Comparison

| Feature | Soft Start | Hard Start |

|---|---|---|

| Definition | Gradual increase of voltage to limit inrush current | Immediate full voltage application at startup |

| Inrush Current | Low, controlled current surge | High, sudden current spike |

| Motor Stress | Reduced mechanical and electrical stress | High mechanical shock and electrical stress |

| Energy Efficiency | Improved energy management during startup | Less efficient due to sudden load |

| Applications | Pumps, conveyors, HVAC systems, sensitive equipment | Simple devices, low-cost equipment |

| Cost | Higher initial cost due to complex circuitry | Lower cost, simpler design |

| Control Complexity | Requires additional control electronics | Minimal control needed |

| Reliability | Increased due to less thermal and mechanical stress | Potentially lower due to harsh startup conditions |

Introduction to Soft Start and Hard Start

Soft start and hard start are two methods used to control the initial power surge in electric motors during startup. Soft start gradually increases the voltage, reducing mechanical stress and electrical peak currents, improving motor longevity and energy efficiency. Hard start applies full voltage instantly, causing higher torque and current spikes, which can lead to increased wear and potential damage to motor components.

Understanding the Basics: What is a Soft Start?

A soft start gradually increases the voltage to electric motors during startup, reducing inrush current and minimizing mechanical stress. This controlled ramp-up helps extend the lifespan of motor components and prevents electrical disturbances in your system. Choosing a soft start improves energy efficiency and provides smoother operation compared to a hard start.

Defining Hard Start: Key Characteristics

Hard start is defined by the immediate application of full voltage to an electric motor at startup, causing a rapid increase in current known as inrush current. This sudden surge generates mechanical stress on motor components and electrical strain on the power supply system. Key characteristics include a high starting torque and potential for increased wear, making hard starts suitable for motors with robust construction and short startup durations.

Major Differences Between Soft Start and Hard Start

Soft start motors gradually increase voltage to reduce inrush current, minimizing mechanical stress and extending equipment life, while hard start motors apply full voltage immediately, causing higher current spikes and potential wear. Soft start systems improve energy efficiency by controlling acceleration, whereas hard start methods lack this regulation, leading to abrupt torque and increased electrical demand. The choice between soft and hard start impacts motor longevity, power consumption, and operational smoothness in industrial applications.

Applications: Where to Use Soft Start vs Hard Start

Soft start is ideal for applications involving heavy machinery or motors requiring gradual power ramp-up to reduce inrush current and mechanical stress, such as HVAC systems, conveyor belts, and large pumps. Hard start is suited for equipment that needs immediate full torque to start, like compressors or refrigeration units, where quick motor engagement prevents operational disruptions. Your choice depends on the load type and the need to protect electrical components from sudden currents or ensure prompt motor activation.

Pros and Cons of Soft Start Systems

Soft start systems reduce inrush current and mechanical stress on motors by gradually increasing voltage, extending equipment lifespan and improving energy efficiency. They provide smoother operation with less electrical noise and lower maintenance costs but may have higher initial investment and require more complex controls. Your choice of a soft start system can enhance reliability and reduce downtime in applications sensitive to power surges.

Pros and Cons of Hard Start Systems

Hard start systems provide immediate full power, enabling rapid motor startup and minimizing initial torque delays, which is beneficial for heavy-duty applications. However, they generate high inrush currents that can stress electrical components and increase the risk of equipment wear or damage. Despite their simplicity and cost-effectiveness, hard start systems may lead to reduced motor lifespan and higher maintenance costs compared to soft start alternatives.

Energy Efficiency Comparison

Soft start motors significantly improve energy efficiency by gradually ramping up power, reducing inrush current and mechanical stress compared to hard start motors that draw maximum current immediately. Your electrical system benefits from lower peak power demand and reduced energy losses, leading to cost savings and extended equipment lifespan. Choosing soft start technology minimizes energy waste and optimizes operational efficiency in industrial and commercial applications.

Cost Considerations and ROI

Soft start motors typically have higher upfront costs due to advanced electronic components but deliver significant energy savings and reduced mechanical wear, improving your long-term ROI. Hard start motors are more affordable initially but may incur higher maintenance and energy expenses over time, lowering overall cost efficiency. Evaluating total lifecycle costs, including installation, maintenance, and operational savings, is crucial for an informed investment decision.

Choosing the Right Start Method for Your Needs

Selecting between soft start and hard start methods depends on your equipment's power requirements and application sensitivity. Soft start reduces inrush current, minimizing mechanical stress and extending the lifespan of motors in HVAC systems or industrial machinery. Your choice impacts energy efficiency and maintenance costs, so evaluate load type and operational frequency to ensure optimal performance.

Soft Start vs Hard Start Infographic

libmatt.com

libmatt.com