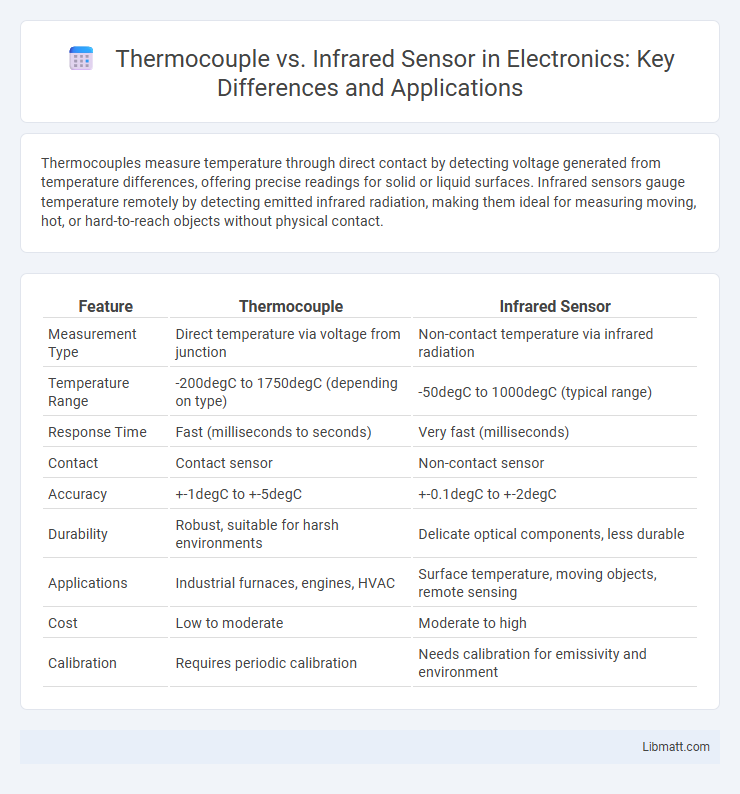

Thermocouples measure temperature through direct contact by detecting voltage generated from temperature differences, offering precise readings for solid or liquid surfaces. Infrared sensors gauge temperature remotely by detecting emitted infrared radiation, making them ideal for measuring moving, hot, or hard-to-reach objects without physical contact.

Table of Comparison

| Feature | Thermocouple | Infrared Sensor |

|---|---|---|

| Measurement Type | Direct temperature via voltage from junction | Non-contact temperature via infrared radiation |

| Temperature Range | -200degC to 1750degC (depending on type) | -50degC to 1000degC (typical range) |

| Response Time | Fast (milliseconds to seconds) | Very fast (milliseconds) |

| Contact | Contact sensor | Non-contact sensor |

| Accuracy | +-1degC to +-5degC | +-0.1degC to +-2degC |

| Durability | Robust, suitable for harsh environments | Delicate optical components, less durable |

| Applications | Industrial furnaces, engines, HVAC | Surface temperature, moving objects, remote sensing |

| Cost | Low to moderate | Moderate to high |

| Calibration | Requires periodic calibration | Needs calibration for emissivity and environment |

Introduction to Temperature Measurement Technologies

Thermocouples and infrared sensors represent two primary temperature measurement technologies with distinct operational principles. Thermocouples measure temperature through voltage changes generated at the junction of two dissimilar metals, offering precise contact-based readings ideal for high-temperature environments. Infrared sensors detect thermal radiation emitted by objects, enabling non-contact temperature measurement, which is essential for applications where direct sensor contact is impractical or could affect your process accuracy.

What is a Thermocouple?

A thermocouple is a temperature measurement device consisting of two dissimilar metal wires joined at one end, creating a junction that generates a voltage proportional to temperature differences. It is widely used for its durability, wide temperature range, and fast response in industrial applications. Your choice between a thermocouple and an infrared sensor depends on factors like contact measurement needs and environmental conditions.

How Thermocouples Work

Thermocouples work by measuring temperature through the thermoelectric effect, where two different metals joined at one end generate a voltage proportional to the temperature difference between the junction and the reference point. This voltage signal is then converted into temperature readings by a microprocessor or temperature controller. Thermocouples are widely used in industrial applications due to their robustness, wide temperature range, and fast response time.

What is an Infrared Sensor?

An infrared sensor detects infrared radiation to measure temperature without physical contact, making it ideal for monitoring moving objects or hazardous environments. Unlike thermocouples, which require direct contact to generate a voltage based on heat, infrared sensors use a lens to focus IR energy onto a detector, providing fast and accurate temperature readings. Your choice depends on whether you need non-contact measurements or precise contact-based temperature data.

How Infrared Sensors Work

Infrared sensors detect temperature by measuring the intensity of infrared radiation emitted from an object's surface, using photodiodes or thermal detectors to convert this radiation into an electrical signal. Unlike thermocouples, which require direct contact to gauge temperature through voltage differences generated by joined metal junctions, infrared sensors provide non-contact temperature measurements. This capability makes infrared sensors ideal for monitoring moving objects or surfaces that are difficult to access safely.

Key Differences Between Thermocouples and Infrared Sensors

Thermocouples measure temperature through direct contact by converting thermal energy into an electrical voltage, making them ideal for high-temperature and harsh environments. Infrared sensors detect temperature remotely by capturing emitted infrared radiation, which allows for non-contact temperature measurement of moving or inaccessible objects. Your choice depends on factors like measurement range, response time, and environmental conditions.

Accuracy and Response Time Comparison

Thermocouples provide high accuracy in temperature measurement, typically within +-1 to +-2degC, making them reliable for direct contact applications, while infrared sensors offer slightly less accuracy, generally around +-2 to +-5degC, due to environmental factors affecting surface temperature readings. Response time for thermocouples is usually faster, often under one second, because they measure temperature through direct contact; infrared sensors may have a slower response time depending on the sensor's design and distance from the target. Your choice between these sensors should consider whether precise, rapid contact measurements or non-contact temperature readings better suit your application needs.

Applications: Where to Use Thermocouples vs Infrared Sensors

Thermocouples are ideal for measuring high-temperature processes such as metal forging, furnace monitoring, and exhaust gas analysis due to their durability and wide temperature range. Infrared sensors excel in non-contact temperature measurements like monitoring moving objects, detecting electrical component overheating, and surface temperature scanning in food processing. Choosing between thermocouples and infrared sensors depends on whether direct contact or remote sensing is required in industrial, manufacturing, or quality control applications.

Advantages and Limitations of Each Technology

Thermocouples offer robust temperature measurement with a wide range, high durability, and fast response times, making them ideal for contact sensing in harsh environments; however, they require physical contact and may suffer from signal noise and calibration drift. Infrared sensors enable non-contact temperature monitoring, providing quick, accurate readings on moving or inaccessible objects, but their accuracy is affected by surface emissivity, ambient conditions, and distance, limiting their use in certain applications. Both technologies serve specific industrial needs, with thermocouples excelling in direct contact measurements and infrared sensors offering versatility in remote temperature sensing.

Choosing the Right Sensor for Your Needs

Selecting the right sensor depends on application requirements such as temperature range, response time, and environmental conditions; thermocouples excel in high-temperature environments up to 1800degC and offer direct contact measurement with high accuracy, while infrared sensors provide non-contact temperature readings suitable for moving objects or hazardous surfaces. Thermocouples require physical connection, making them ideal for industrial processes needing precise heat monitoring, whereas infrared sensors offer versatility in measuring temperature from a distance, ideal for monitoring delicate or electrically active components. Consider factors such as measurement accuracy, installation complexity, and response speed to determine the most effective sensor for your specific temperature monitoring needs.

Thermocouple vs Infrared Sensor Infographic

libmatt.com

libmatt.com