Planar MOSFETs feature a flat channel structure ideal for low-voltage applications, while Trench MOSFETs utilize a vertical channel design that enhances current capacity and efficiency in high-power environments. Choosing the right MOSFET depends on your specific needs for switching speed, thermal performance, and device miniaturization.

Table of Comparison

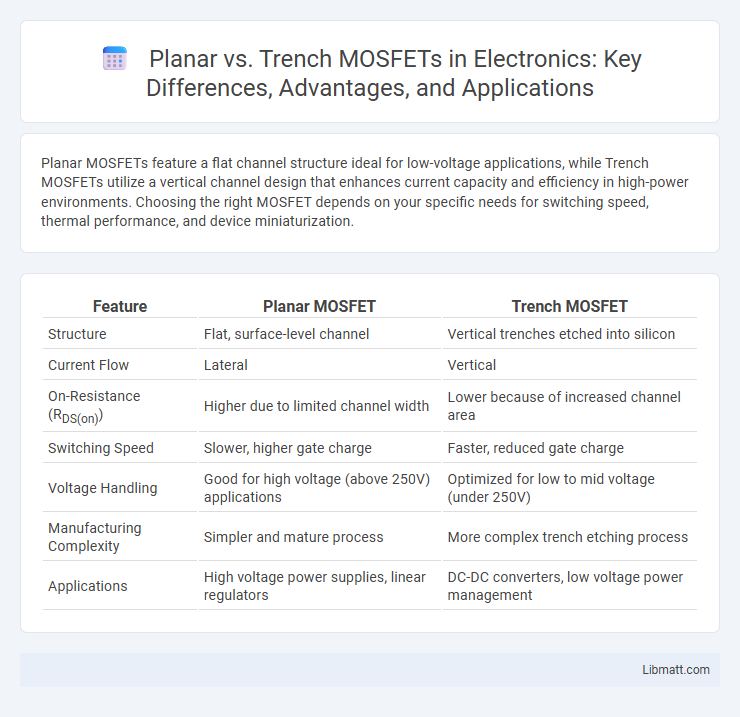

| Feature | Planar MOSFET | Trench MOSFET |

|---|---|---|

| Structure | Flat, surface-level channel | Vertical trenches etched into silicon |

| Current Flow | Lateral | Vertical |

| On-Resistance (RDS(on)) | Higher due to limited channel width | Lower because of increased channel area |

| Switching Speed | Slower, higher gate charge | Faster, reduced gate charge |

| Voltage Handling | Good for high voltage (above 250V) applications | Optimized for low to mid voltage (under 250V) |

| Manufacturing Complexity | Simpler and mature process | More complex trench etching process |

| Applications | High voltage power supplies, linear regulators | DC-DC converters, low voltage power management |

Introduction to MOSFET Technologies

Planar MOSFET technology features a horizontal channel with gate electrodes positioned above the silicon surface, optimized for low voltage and moderate power applications. Trench MOSFETs use vertically etched trenches to form the gate, enabling higher cell density and lower on-resistance, ideal for high-current and switching efficiency demands. Understanding these differences helps you select the appropriate MOSFET type for your power management needs.

Understanding Planar MOSFET Architecture

Planar MOSFET architecture features a flat silicon surface with source, drain, and gate terminals aligned horizontally, enabling straightforward fabrication and effective control of the channel region. The gate oxide insulator sits directly above the channel, allowing voltage application to modulate current flow efficiently. This conventional design provides reliable performance but faces limitations in scaling and short-channel effects compared to advanced structures such as trench MOSFETs.

Overview of Trench MOSFET Structure

Trench MOSFETs feature a vertical gate structure etched deep into the silicon substrate, allowing for reduced on-resistance and improved current flow compared to Planar MOSFETs. This design increases the effective channel width per unit area, enhancing switching performance and power efficiency. Your choice of Trench MOSFET can significantly optimize device performance in high-density power applications.

Key Differences Between Planar and Trench MOSFETs

Planar MOSFETs feature a flat surface structure with a lateral current flow, while Trench MOSFETs utilize a vertical current flow through deep trenches etched into the silicon, enhancing channel density. The trench design offers lower on-resistance (R_DS(on)) and improved switching performance compared to planar devices, making them ideal for high-efficiency power applications. Heat dissipation and compactness are optimized in Trench MOSFETs, providing superior thermal management and higher current handling in smaller footprints.

Performance Comparison: Efficiency and Conductivity

Trench MOSFETs exhibit higher efficiency and improved conductivity compared to planar MOSFETs due to their vertical channel structure, which reduces on-resistance (R_DS(on)) and enhances current density. The trench design allows for a larger effective gate area, resulting in lower gate charge and faster switching speeds. Planar MOSFETs typically suffer from higher parasitic capacitances and lower efficiency at high frequencies, making trench MOSFETs preferable for power-sensitive and high-performance applications.

Switching Speed Considerations

Trench MOSFETs typically offer faster switching speeds than Planar MOSFETs due to their lower gate charge and reduced gate-to-drain capacitance, which minimizes switching losses and improves efficiency. Your choice between Planar and Trench technologies impacts switching performance, especially in high-frequency applications where rapid transitions are critical. Optimizing switching speed with Trench MOSFETs enhances power conversion and thermal management in demanding electronic circuits.

Thermal Management and Reliability

Trench MOSFETs offer superior thermal management due to their vertical structure, which enhances heat dissipation and reduces thermal resistance compared to planar MOSFETs. The improved thermal conductivity in trench designs leads to better reliability under high-power conditions by minimizing hotspot formation and thermal stress. Planar MOSFETs, while simpler, tend to exhibit higher junction temperatures that can accelerate device degradation and limit operational lifespan.

Application Suitability: Where Each Excels

Planar MOSFETs excel in low-voltage, high-speed switching applications such as power supplies and motor drives due to their simpler structure and lower manufacturing costs. Trench MOSFETs are ideal for high-current, high-efficiency applications like automotive electronics and server power management, benefiting from lower on-resistance (R_DS(on)) and improved thermal performance. The trench design enables superior scalability and reduced switching losses, making it preferable for energy-efficient systems requiring compact and robust power devices.

Cost Implications and Manufacturing Complexity

Planar MOSFETs typically have lower manufacturing complexity and cost due to their well-established, mature fabrication processes, making them cost-effective for high-volume, low-voltage applications. Trench MOSFETs, while more expensive to produce because of advanced etching and insulating techniques, offer superior performance in terms of reduced on-resistance and improved efficiency, justifying higher costs in power-sensitive and high-performance devices. The trade-off between cost and complexity depends heavily on the target application, with planar designs favored for budget-sensitive markets and trench designs for optimized power handling.

Future Trends in MOSFET Design

Future trends in MOSFET design emphasize increased energy efficiency and miniaturization, with Trench MOSFETs offering superior switching speeds and lower on-resistance compared to Planar MOSFETs. Advancements in wide bandgap materials such as silicon carbide (SiC) and gallium nitride (GaN) are driving the evolution of Trench MOSFET structures for high-power and high-frequency applications. Integration of 3D architectures and improved thermal management techniques are expected to further enhance the performance and reliability of next-generation MOSFET devices.

Planar vs Trench MOSFET Infographic

libmatt.com

libmatt.com