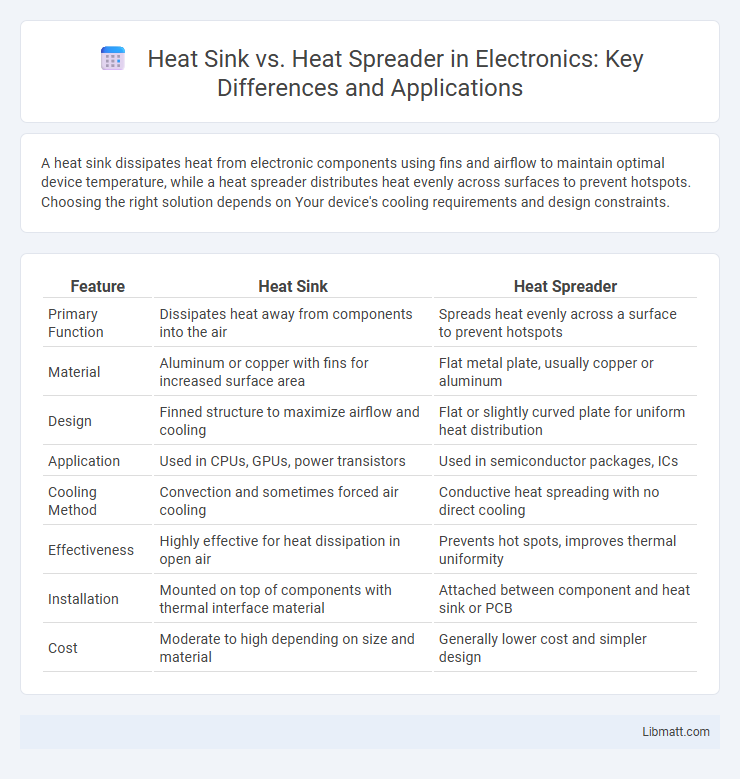

A heat sink dissipates heat from electronic components using fins and airflow to maintain optimal device temperature, while a heat spreader distributes heat evenly across surfaces to prevent hotspots. Choosing the right solution depends on Your device's cooling requirements and design constraints.

Table of Comparison

| Feature | Heat Sink | Heat Spreader |

|---|---|---|

| Primary Function | Dissipates heat away from components into the air | Spreads heat evenly across a surface to prevent hotspots |

| Material | Aluminum or copper with fins for increased surface area | Flat metal plate, usually copper or aluminum |

| Design | Finned structure to maximize airflow and cooling | Flat or slightly curved plate for uniform heat distribution |

| Application | Used in CPUs, GPUs, power transistors | Used in semiconductor packages, ICs |

| Cooling Method | Convection and sometimes forced air cooling | Conductive heat spreading with no direct cooling |

| Effectiveness | Highly effective for heat dissipation in open air | Prevents hot spots, improves thermal uniformity |

| Installation | Mounted on top of components with thermal interface material | Attached between component and heat sink or PCB |

| Cost | Moderate to high depending on size and material | Generally lower cost and simpler design |

Introduction to Heat Sinks and Heat Spreaders

Heat sinks and heat spreaders are essential thermal management components used to dissipate heat from electronic devices, ensuring optimal performance and longevity. Heat sinks typically feature fins that increase surface area to facilitate heat transfer to the surrounding air, while heat spreaders distribute heat across a broader area to prevent hotspots. Both components play critical roles in improving thermal efficiency in CPUs, GPUs, and power electronics.

Core Functions: Dissipation vs Distribution

Heat sinks excel at heat dissipation by increasing surface area to transfer heat away from components using fins and airflow. Heat spreaders focus on heat distribution, evenly spreading thermal energy across a broader surface to prevent hotspots on chips. Your choice depends on whether efficient heat removal or uniform thermal management is the priority for your device.

How Heat Sinks Work

Heat sinks function by dissipating heat from electronic components through conduction, with thermally conductive materials like aluminum or copper drawing heat away from the source. The increased surface area of fins or pins allows for enhanced convection, transferring heat to the surrounding air more efficiently. This process lowers the temperature of critical parts, preventing overheating and maintaining optimal device performance.

How Heat Spreaders Operate

Heat spreaders operate by rapidly dispersing heat away from a concentrated source, such as a CPU or GPU, across a larger surface area to improve thermal management. They are typically made of highly conductive materials like copper or aluminum, which facilitate efficient heat transfer and reduce hotspots. Unlike heat sinks, heat spreaders do not rely on fins or active cooling but enhance overall system reliability by evenly distributing heat before it is dissipated by subsequent cooling components.

Key Material Differences

Heat sinks are typically made from aluminum or copper due to their excellent thermal conductivity, allowing efficient heat dissipation from electronic components. Heat spreaders generally use copper or nickel-plated copper to evenly distribute heat across a broader surface area, preventing hotspots. Your choice depends on the specific thermal management needs, as heat sinks excel in cooling through airflow, while heat spreaders focus on heat distribution within confined spaces.

Applications in Modern Electronics

Heat sinks are essential in modern electronics for dissipating heat from high-power devices such as CPUs, GPUs, and power transistors, ensuring stable operation and preventing thermal damage. Heat spreaders distribute heat across a larger surface area in applications like smartphone processors and LED modules, enhancing thermal management in compact designs. Both components play critical roles in maintaining device performance and reliability by optimizing heat transfer in advanced electronic systems.

Performance Comparison: Heat Management Efficiency

Heat sinks offer superior heat management efficiency by dissipating heat through extended surface area and passive airflow, making them ideal for high-performance CPU cooling. Heat spreaders excel at quickly distributing heat across a broader area, reducing hotspots and improving thermal uniformity but may require additional cooling components for optimal performance. Your choice depends on whether you prioritize direct heat dissipation or efficient heat distribution for your device's cooling needs.

Factors to Consider When Choosing

When choosing between a heat sink and a heat spreader, consider factors such as thermal conductivity, surface area, and device power dissipation. Heat sinks excel in maximizing surface area for effective heat dissipation through fins, making them ideal for high-power electronics. Heat spreaders provide uniform heat distribution over a broader area, which is beneficial for components requiring even thermal management and moderate heat reduction.

Cost and Design Implications

Heat sinks generally incur higher manufacturing costs due to complex fin structures that maximize surface area for efficient heat dissipation, while heat spreaders offer a cost-effective solution with simpler flat or slightly curved designs. The intricate metal fins of heat sinks require precision machining or extrusion, increasing production time and materials, whereas heat spreaders utilize thin metal plates that evenly distribute heat without extensive fabrication. Design implications include the bulkier profile and increased weight of heat sinks compared to the slim, lightweight form factor of heat spreaders, influencing application choices based on thermal requirements and budget constraints.

Future Trends in Thermal Management Solutions

Future trends in thermal management solutions emphasize advanced materials with superior thermal conductivity, such as graphene-enhanced heat sinks and diamond-based heat spreaders, enabling more efficient heat dissipation in increasingly compact electronics. Integration of microchannel heat sinks and vapor chambers combined with adaptive thermal interface materials supports dynamic cooling based on real-time temperature monitoring. Enhanced design approaches leveraging additive manufacturing and AI-driven optimization promise customized, high-performance thermal solutions that address the growing thermal demands of next-generation processors and power electronics.

Heat Sink vs Heat Spreader Infographic

libmatt.com

libmatt.com