Surface Mount Device (SMD) refers to the actual electronic components designed for surface mounting, while Surface Mount Technology (SMT) encompasses the entire assembly process used to place these components onto printed circuit boards (PCBs). Understanding the distinction between SMD components and SMT processes is essential for optimizing your electronics manufacturing and assembly efficiency.

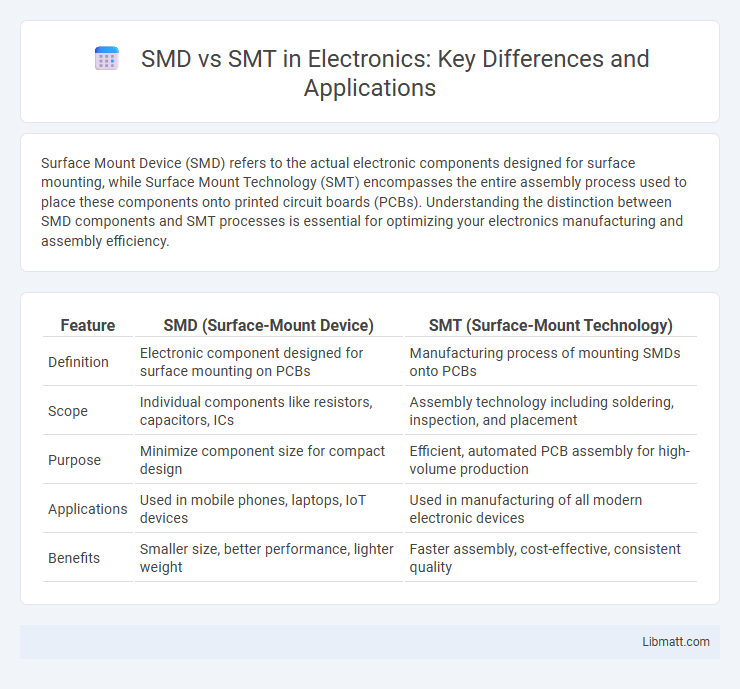

Table of Comparison

| Feature | SMD (Surface-Mount Device) | SMT (Surface-Mount Technology) |

|---|---|---|

| Definition | Electronic component designed for surface mounting on PCBs | Manufacturing process of mounting SMDs onto PCBs |

| Scope | Individual components like resistors, capacitors, ICs | Assembly technology including soldering, inspection, and placement |

| Purpose | Minimize component size for compact design | Efficient, automated PCB assembly for high-volume production |

| Applications | Used in mobile phones, laptops, IoT devices | Used in manufacturing of all modern electronic devices |

| Benefits | Smaller size, better performance, lighter weight | Faster assembly, cost-effective, consistent quality |

Understanding SMD and SMT: Key Definitions

Surface-Mount Devices (SMD) are electronic components designed for direct placement on the surface of printed circuit boards (PCBs), enabling compact and efficient circuit designs. Surface-Mount Technology (SMT) refers to the manufacturing process used to attach and solder these SMD components onto PCBs, enhancing automation and reducing assembly time. SMT facilitates high-density circuitry and improved electrical performance compared to traditional through-hole technology.

The History and Evolution of Surface Mount Technology

Surface Mount Technology (SMT) evolved from the early use of Small Metal Devices (SMD) to enable automated assembly of electronic components directly onto printed circuit boards. Since its introduction in the 1960s, SMT revolutionized manufacturing by allowing higher component density, reduced lead lengths, and improved electrical performance compared to traditional through-hole techniques. Your understanding of SMT's development highlights the shift towards miniaturization and efficiency that shapes modern electronics production.

SMD vs SMT: What’s the Real Difference?

SMD (Surface-Mount Device) refers to the actual electronic components designed for surface-mount technology assembly, while SMT (Surface-Mount Technology) is the manufacturing process used to place and solder these components onto printed circuit boards (PCBs). The key difference lies in SMD representing the physical components and SMT representing the method of assembly. Understanding this distinction is crucial for PCB design and electronics manufacturing efficiency.

Components Used in SMD Assembly

Surface-Mount Device (SMD) assembly primarily employs components like resistors, capacitors, diodes, and integrated circuits designed with flat leads or terminations for direct mounting on PCB surfaces. These components feature smaller sizes and standardized packages such as SOIC, QFN, and BGA, enabling high-density circuit layouts and automated placement. Your choice of SMD components impacts assembly efficiency and performance in surface-mount technology (SMT) processes.

SMT Process Overview: How Surface Mount Technology Works

Surface Mount Technology (SMT) involves placing electronic components directly onto the surface of printed circuit boards (PCBs), contrasting with traditional through-hole methods. The SMT process includes solder paste application, precise component placement using automated machines, and reflow soldering to secure components firmly onto the board. This efficient method supports high-density PCB designs and enhances your device's performance by ensuring reliable electrical connections and reduced production time.

Advantages of SMD Components

SMD (Surface-Mount Device) components offer significant advantages over traditional through-hole SMT (Surface Mount Technology) parts, including smaller size and lighter weight, which allow for higher component density and more compact circuit designs. They provide improved electrical performance due to shorter lead lengths, reducing parasitic inductance and capacitance, which enhances signal integrity in high-frequency applications. Automated placement and soldering of SMDs also result in faster production speeds, higher reliability, and reduced manufacturing costs.

SMT vs Through-Hole Technology: A Comparative Analysis

Surface Mount Technology (SMT) offers higher component density and automated assembly, reducing production time compared to Through-Hole Technology, which involves inserting leads into drilled holes for mechanical strength. SMT enables smaller, lighter devices with improved electrical performance, while Through-Hole provides superior mechanical bonding suitable for heavy components and high-stress applications. Your choice depends on factors like device size, reliability requirements, and manufacturing scale, with SMT favored in modern electronics for efficiency and miniaturization.

Common Applications of SMD and SMT

Surface Mount Devices (SMD) are extensively used in compact consumer electronics such as smartphones, laptops, and wearables due to their small size and high efficiency. Surface Mount Technology (SMT) enables precise placement of these components on printed circuit boards, supporting high-volume manufacturing for automotive, aerospace, and medical device industries. The integration of SMD with SMT processes allows for improved performance, reduced assembly time, and enhanced reliability across various electronic applications.

Challenges and Limitations of SMD/SMT

Surface-Mount Devices (SMD) and Surface-Mount Technology (SMT) face challenges such as precise placement requirements due to miniature component sizes, increasing the risk of misalignment during automated assembly. Thermal management poses limitations since smaller components are more susceptible to heat damage during soldering processes. Inspection and repair complexity rises as tiny SMD components often require advanced imaging and specialized tools to detect defects and ensure quality control.

Future Trends in Surface Mount Technology

Future trends in Surface Mount Technology (SMT) highlight increased adoption of miniaturized components like 0201 and 01005 size packages to enhance circuit density and performance. Advanced automated placement machines and AI-driven inspection systems improve production accuracy and speed, reducing defects in Surface Mount Devices (SMD). Your manufacturing efficiency will benefit from innovations like 3D printing and flexible PCBs, which expand SMT applications in IoT and wearable electronics.

SMD vs SMT Infographic

libmatt.com

libmatt.com