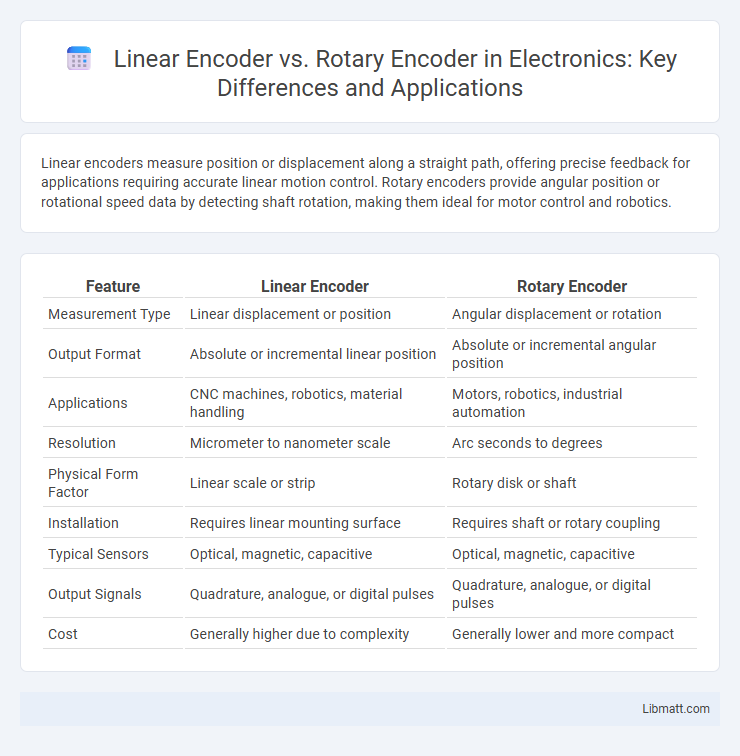

Linear encoders measure position or displacement along a straight path, offering precise feedback for applications requiring accurate linear motion control. Rotary encoders provide angular position or rotational speed data by detecting shaft rotation, making them ideal for motor control and robotics.

Table of Comparison

| Feature | Linear Encoder | Rotary Encoder |

|---|---|---|

| Measurement Type | Linear displacement or position | Angular displacement or rotation |

| Output Format | Absolute or incremental linear position | Absolute or incremental angular position |

| Applications | CNC machines, robotics, material handling | Motors, robotics, industrial automation |

| Resolution | Micrometer to nanometer scale | Arc seconds to degrees |

| Physical Form Factor | Linear scale or strip | Rotary disk or shaft |

| Installation | Requires linear mounting surface | Requires shaft or rotary coupling |

| Typical Sensors | Optical, magnetic, capacitive | Optical, magnetic, capacitive |

| Output Signals | Quadrature, analogue, or digital pulses | Quadrature, analogue, or digital pulses |

| Cost | Generally higher due to complexity | Generally lower and more compact |

Introduction to Encoders

Encoders are essential devices used to convert motion into electrical signals, enabling precise position and speed detection in automation systems. Linear encoders measure straight-line displacement, making them ideal for applications requiring accurate linear position feedback. Rotary encoders detect angular position or rotational speed, commonly used in motors and rotary systems to provide precise rotational measurement.

What is a Linear Encoder?

A linear encoder is a position feedback device that measures displacement along a straight path by converting linear motion into an electronic signal. It uses scales with precise pitch markings and optical, magnetic, or capacitive sensors to detect positional changes with high accuracy. Linear encoders are essential in applications requiring precise linear positioning, such as CNC machines, semiconductor manufacturing, and metrology equipment.

What is a Rotary Encoder?

A rotary encoder is an electromechanical device that converts the angular position or motion of a rotating shaft into digital signals, providing precise measurement of rotational speed, direction, and position. Unlike linear encoders that track straight-line movement, rotary encoders are essential in applications requiring feedback on circular motion, such as robotics, CNC machines, and rotary actuators. Your choice between linear and rotary encoders depends on whether you need to monitor linear displacement or rotational motion with high accuracy.

Working Principle: Linear vs Rotary Encoders

Linear encoders operate by translating the position of a scale or strip into electrical signals corresponding to linear displacement, using optical, magnetic, or capacitive sensing methods. Rotary encoders detect angular position or rotational motion by converting the angular displacement of a rotating shaft into electrical pulses through incremental or absolute measurement techniques. Both encoder types generate precise feedback for motion control, but linear encoders measure straight-line movements while rotary encoders track rotational movements.

Key Applications of Linear Encoders

Linear encoders are commonly used in precision measurement applications such as CNC machines, coordinate measuring machines (CMMs), and semiconductor manufacturing equipment where accurate position feedback is critical. They provide high-resolution, direct measurement of linear displacement, enabling precise control in automation, robotics, and material testing systems. Compared to rotary encoders, linear encoders excel in applications requiring exact linear positioning without the need for conversion from rotational data.

Key Applications of Rotary Encoders

Rotary encoders are widely used in industrial automation for precise motor control and robotics, enabling accurate position feedback and speed monitoring. They are crucial in CNC machines, providing real-time angular position data to ensure high-precision machining processes. Additionally, rotary encoders play a vital role in conveyor systems and elevators, facilitating smooth and efficient motion control.

Advantages and Disadvantages

Linear encoders provide precise position measurement with high accuracy and are ideal for applications requiring direct linear displacement tracking, but they can be more susceptible to contamination and mechanical wear. Rotary encoders excel in measuring angular position with a compact design and are generally more robust in harsh environments, though they require additional calculations for linear displacement and may introduce cumulative errors in extended motion. Selecting between them depends on the specific application needs, such as required resolution, environmental conditions, and mechanical setup.

Accuracy and Resolution Comparison

Linear encoders typically offer higher accuracy and finer resolution compared to rotary encoders due to their direct measurement of position along a straight axis, minimizing cumulative errors associated with rotational measurements. Rotary encoders, while effective for angular position sensing, often provide lower resolution because their output depends on the number of pulses per revolution, which can be limited by mechanical design and sensor technology. Your choice between the two should consider the precision requirements of your application, with linear encoders preferred for tasks demanding exceptional positional accuracy and resolution.

Cost and Installation Considerations

Linear encoders typically have a higher initial cost due to their precision components and require careful alignment along a straight path, which can increase installation complexity and time. Rotary encoders generally offer a more affordable solution with simpler installation since they attach directly to rotating shafts, making them suitable for applications where space and ease of setup are priorities. Your choice between the two should balance budget constraints with the mechanical design and precision requirements of your project.

Choosing the Right Encoder for Your Needs

Choosing the right encoder depends on the specific application requirements and measurement type, with linear encoders providing precise position feedback along a straight path and rotary encoders offering accurate angular position or rotational speed data. Factors such as resolution, environmental conditions, installation space, and required accuracy dictate whether a linear or rotary encoder is ideal for your needs. Understanding these parameters ensures optimal performance in automation, robotics, or CNC machinery.

Linear encoder vs Rotary encoder Infographic

libmatt.com

libmatt.com