Acrylic PCB coatings offer fast-drying properties and easy reworkability, making them ideal for applications requiring frequent maintenance, while epoxy coatings provide superior moisture resistance and mechanical protection, ensuring long-term durability in harsh environments. Choosing between acrylic and epoxy depends on your priority for either quick application and repair or robust, lasting protection against environmental factors.

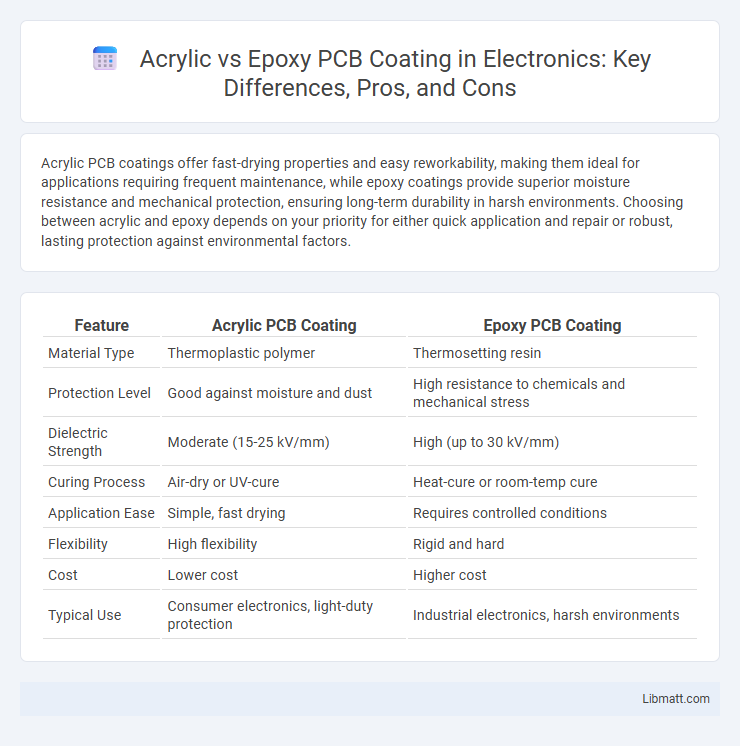

Table of Comparison

| Feature | Acrylic PCB Coating | Epoxy PCB Coating |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermosetting resin |

| Protection Level | Good against moisture and dust | High resistance to chemicals and mechanical stress |

| Dielectric Strength | Moderate (15-25 kV/mm) | High (up to 30 kV/mm) |

| Curing Process | Air-dry or UV-cure | Heat-cure or room-temp cure |

| Application Ease | Simple, fast drying | Requires controlled conditions |

| Flexibility | High flexibility | Rigid and hard |

| Cost | Lower cost | Higher cost |

| Typical Use | Consumer electronics, light-duty protection | Industrial electronics, harsh environments |

Overview of PCB Protective Coatings

Acrylic and epoxy coatings provide essential protection for printed circuit boards (PCBs) against moisture, dust, and chemical exposure. Acrylic coatings offer excellent UV resistance and flexibility, making them suitable for applications requiring frequent handling or exposure to sunlight. Epoxy coatings deliver superior mechanical strength and chemical resistance, ideal for harsh industrial environments where durability and long-term reliability are critical.

What is Acrylic PCB Coating?

Acrylic PCB coating is a protective layer applied to printed circuit boards to shield them from moisture, dust, and chemicals while providing electrical insulation. This coating is known for its quick drying time, clarity, and ease of application, making it ideal for environments where moderate protection is sufficient. Your PCB benefits from enhanced durability and reduced risk of corrosion or short circuits with acrylic coatings, especially in less demanding industrial applications.

What is Epoxy PCB Coating?

Epoxy PCB coating is a protective resin applied to printed circuit boards that creates a durable, chemical-resistant barrier against moisture, dust, and contaminants. This thermosetting polymer enhances electrical insulation and mechanical strength, improving the board's reliability in harsh environments. Epoxy coatings are preferred for applications requiring robust protection due to their excellent adhesion and resistance to heat and corrosion.

Key Differences Between Acrylic and Epoxy Coatings

Acrylic PCB coatings offer faster drying times and are easier to apply, making them suitable for quick prototyping and low-cost electronics, whereas epoxy coatings provide superior chemical resistance and mechanical strength, ideal for harsh industrial environments. Acrylic coatings typically have lower chemical and temperature resistance compared to epoxy, which excels in protecting circuits against moisture, corrosion, and abrasion. The choice between acrylic and epoxy PCB coatings depends on the specific application requirements for durability, environmental exposure, and electrical insulation properties.

Application Methods: Acrylic vs Epoxy

Acrylic PCB coatings are typically applied using brushing, spraying, or dipping methods, allowing for quick drying and easy rework during manufacturing. Epoxy coatings, on the other hand, often require precise mixing and use of dispensing or spraying techniques to ensure a uniform, durable layer with strong chemical resistance. You should choose acrylic for faster application and flexibility, while epoxy is preferable for thicker, more robust protective coatings on PCBs.

Durability and Protection: Which Coating Performs Better?

Epoxy PCB coatings offer superior durability and chemical resistance compared to acrylic coatings, providing enhanced protection against moisture, solvents, and mechanical wear. Acrylic coatings, while easier to apply and rework, typically provide less robust protection in harsh environments due to their lower hardness and chemical resistance. For applications requiring long-term durability and high-performance protection, epoxy coatings are generally the preferred choice.

Chemical and Environmental Resistance Comparison

Epoxy PCB coatings provide superior chemical resistance against solvents, oils, and corrosive agents compared to acrylic coatings, making them ideal for harsh industrial environments. Acrylic coatings offer moderate environmental resistance with good UV stability and moisture protection but are less durable against aggressive chemicals and abrasion. Epoxy coatings generally exhibit higher durability and longer-term protection in chemically demanding and high-humidity exposure scenarios.

Cost-Effectiveness: Acrylic vs Epoxy Coatings

Acrylic PCB coatings generally cost less than epoxy coatings, making them a more budget-friendly option for projects with cost constraints. Epoxy coatings offer superior chemical resistance and durability but come at a higher price point due to their complex formulation and application process. Your choice between acrylic and epoxy should consider both the initial expense and the long-term protection performance required for your PCB.

Best Use Cases for Acrylic and Epoxy PCB Coatings

Acrylic PCB coatings are best suited for applications requiring quick curing times and easy rework, making them ideal for consumer electronics and prototyping. Epoxy coatings provide superior chemical resistance and mechanical protection, which benefits industrial machinery and outdoor electronics exposed to harsh environments. Choosing the right coating depends on Your need for durability versus ease of maintenance in the specific operational context.

How to Choose the Right PCB Coating for Your Project

Selecting the ideal PCB coating involves evaluating factors like environmental exposure, chemical resistance, and electrical insulation needs. Acrylic coatings provide easy application and reworkability, making them suitable for general protection in low-humidity environments. Epoxy coatings offer superior durability and chemical resistance, recommended for harsh conditions requiring robust mechanical protection and long-term reliability.

Acrylic vs Epoxy PCB coating Infographic

libmatt.com

libmatt.com