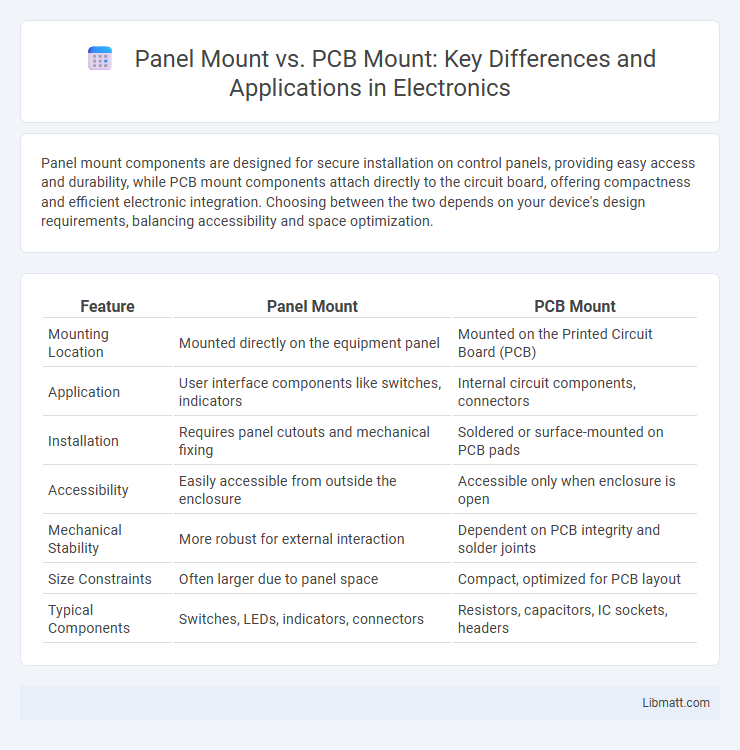

Panel mount components are designed for secure installation on control panels, providing easy access and durability, while PCB mount components attach directly to the circuit board, offering compactness and efficient electronic integration. Choosing between the two depends on your device's design requirements, balancing accessibility and space optimization.

Table of Comparison

| Feature | Panel Mount | PCB Mount |

|---|---|---|

| Mounting Location | Mounted directly on the equipment panel | Mounted on the Printed Circuit Board (PCB) |

| Application | User interface components like switches, indicators | Internal circuit components, connectors |

| Installation | Requires panel cutouts and mechanical fixing | Soldered or surface-mounted on PCB pads |

| Accessibility | Easily accessible from outside the enclosure | Accessible only when enclosure is open |

| Mechanical Stability | More robust for external interaction | Dependent on PCB integrity and solder joints |

| Size Constraints | Often larger due to panel space | Compact, optimized for PCB layout |

| Typical Components | Switches, LEDs, indicators, connectors | Resistors, capacitors, IC sockets, headers |

Introduction to Component Mounting Methods

Panel mount and PCB mount represent two fundamental component mounting methods in electronic device assembly. Panel mount involves securing components directly onto the device's exterior panel for easy user access and durability, commonly used for controls and indicators. PCB mount attaches components onto the printed circuit board, optimizing internal space and electrical connectivity for compact and complex circuit designs.

What is Panel Mount?

Panel mount refers to a method of installing electronic components by securing them directly through a hole in a control panel or enclosure, allowing for easy access and user interaction. These components, such as switches, indicators, or connectors, are designed to be mounted flush with or protruding from the panel surface for durability and aesthetic integration. Your choice of panel mount ensures reliable operation in environments requiring frequent adjustments or monitoring.

What is PCB Mount?

PCB mount refers to a method of attaching electronic components directly onto a printed circuit board (PCB) through holes or surface mounting techniques, ensuring secure electrical connections and compact design. Common for resistors, capacitors, and integrated circuits, PCB mounting optimizes space and simplifies automated assembly processes in modern electronics. This mounting style contrasts with panel mount, which involves securing components to the device enclosure, impacting accessibility and device layout.

Key Differences Between Panel Mount and PCB Mount

Panel mount components are designed for installation on the front panel of a device, providing easy access and user interaction, while PCB mount components are soldered directly onto a printed circuit board for compact and secure electrical connections. Panel mounts typically offer robust mechanical support and enhanced durability in user-accessible areas, whereas PCB mounts prioritize space efficiency and integration within the device's circuitry. The key differences lie in their mounting location, mechanical stability, accessibility, and intended application within electronic assemblies.

Advantages of Panel Mount Components

Panel mount components offer enhanced durability and ease of access for maintenance and replacement, making them ideal for applications requiring frequent user interaction or environmental exposure. They provide superior stability and secure fastening directly onto panels or enclosures, reducing strain on circuit boards. Your design benefits from simplified wiring and improved ergonomics, ensuring reliable performance in industrial and consumer electronics.

Advantages of PCB Mount Components

PCB mount components offer significant advantages in automated manufacturing processes, enabling faster assembly and reduced labor costs due to their compatibility with surface-mount technology (SMT) and through-hole technology (THT). These components provide greater design flexibility and higher component density on printed circuit boards, promoting compact and lightweight electronic devices. Enhanced electrical performance and improved mechanical stability result from direct soldering to the PCB, minimizing connection issues and enhancing overall device reliability.

Typical Applications for Panel Mount

Panel mount components are widely used in industrial control systems, medical devices, and automotive dashboards due to their robust design and ease of access for user interface elements like switches, indicators, and connectors. They are ideal for applications requiring frequent user interaction and environmental protection, such as outdoor equipment, instrumentation panels, and telecommunications racks. Their secure mounting method ensures stability in high-vibration or high-impact settings, making them suitable for harsh operating environments.

Typical Applications for PCB Mount

PCB mounts are commonly used in compact electronic devices where space efficiency and automated assembly are critical, such as smartphones, laptops, and wearable technology. Their integration into printed circuit boards allows for reliable electrical connections in consumer electronics, telecommunications equipment, and automotive control systems. The preference for PCB mounts in these applications is due to their ability to support high-density component placement and streamline manufacturing processes.

Factors to Consider When Choosing Mounting Types

When selecting between panel mount and PCB mount, consider factors such as space constraints, environmental exposure, and ease of installation. Panel mounts offer better accessibility and durability for external controls, while PCB mounts provide compact integration and cost efficiency for internal circuitry. Electrical connectivity requirements and mechanical stability also play crucial roles in determining the appropriate mounting type for a specific application.

Conclusion: Choosing the Right Mounting Solution

Selecting the right mounting solution depends on your device's design requirements and space constraints. Panel mount options offer easier accessibility and better durability for user interfaces, while PCB mount solutions provide compact integration and cost efficiency on circuit boards. Evaluating your project's functionality and installation environment ensures you choose the optimal mount for performance and reliability.

Panel Mount vs PCB Mount Infographic

libmatt.com

libmatt.com