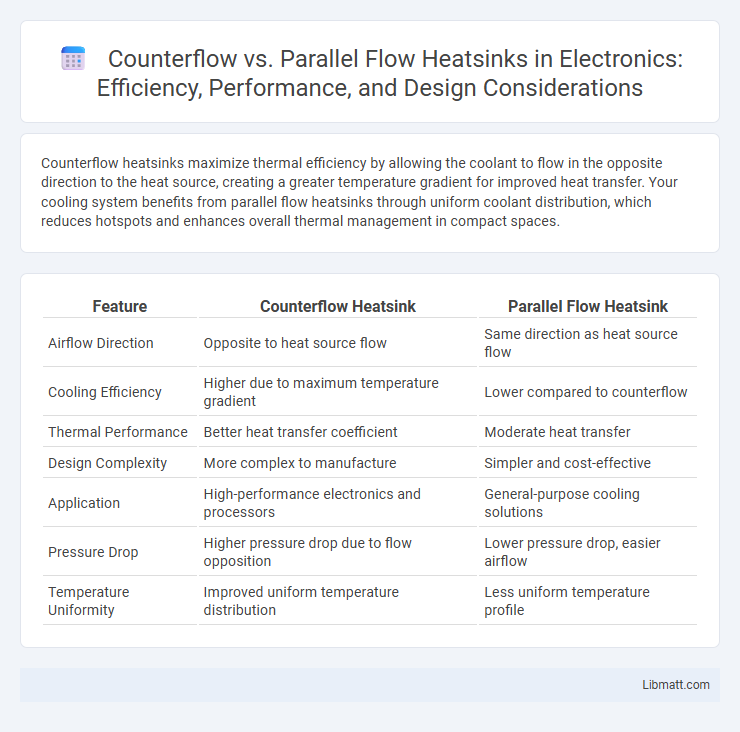

Counterflow heatsinks maximize thermal efficiency by allowing the coolant to flow in the opposite direction to the heat source, creating a greater temperature gradient for improved heat transfer. Your cooling system benefits from parallel flow heatsinks through uniform coolant distribution, which reduces hotspots and enhances overall thermal management in compact spaces.

Table of Comparison

| Feature | Counterflow Heatsink | Parallel Flow Heatsink |

|---|---|---|

| Airflow Direction | Opposite to heat source flow | Same direction as heat source flow |

| Cooling Efficiency | Higher due to maximum temperature gradient | Lower compared to counterflow |

| Thermal Performance | Better heat transfer coefficient | Moderate heat transfer |

| Design Complexity | More complex to manufacture | Simpler and cost-effective |

| Application | High-performance electronics and processors | General-purpose cooling solutions |

| Pressure Drop | Higher pressure drop due to flow opposition | Lower pressure drop, easier airflow |

| Temperature Uniformity | Improved uniform temperature distribution | Less uniform temperature profile |

Introduction to Heatsink Flow Configurations

Counterflow and parallel flow heatsinks differ primarily in the direction of coolant or airflow relative to the heat source. Counterflow configuration allows the cooling medium to enter opposite to the heat source flow, maximizing temperature gradient and enhancing heat transfer efficiency. Your choice between these configurations influences thermal performance, fluid dynamics, and overall cooling effectiveness in electronic systems.

Understanding Counterflow and Parallel Flow

Counterflow and parallel flow heatsinks differ in how coolant moves relative to the heat source; counterflow directs the coolant in the opposite direction of heat transfer, maximizing temperature gradient and efficiency. Parallel flow moves the coolant in the same direction, offering simpler design but typically lower thermal performance compared to counterflow. Understanding these flow dynamics helps optimize your heatsink choice for enhanced cooling and reliable thermal management.

Key Differences Between Counterflow and Parallel Flow

Counterflow heatsinks feature fluid streams moving in opposite directions, enabling higher heat transfer efficiency due to a greater temperature gradient across the surface. Parallel flow heatsinks have fluids flowing in the same direction, resulting in a lower temperature difference and reduced thermal performance. Understanding these flow dynamics helps optimize Your cooling system by selecting the appropriate heatsink configuration for maximum heat dissipation.

Heat Transfer Efficiency: Counterflow vs. Parallel Flow

Counterflow heatsinks deliver superior heat transfer efficiency by maintaining a higher temperature gradient between the heat source and cooling medium throughout the entire length of the device, enabling more effective thermal energy exchange. Parallel flow designs often experience reduced efficiency due to the diminishing temperature difference along the flow path, limiting their ability to dissipate heat consistently. Choosing a counterflow heatsink for your cooling system can significantly enhance thermal management performance in high-demand applications.

Temperature Gradient Analysis in Both Systems

Counterflow heatsinks exhibit a more uniform temperature gradient due to the opposing direction of fluid flow, enhancing heat transfer efficiency by maintaining higher temperature differences along the heat exchange surface. Parallel flow heatsinks show a steeper temperature gradient near the inlet, resulting in reduced thermal performance as the temperature difference decreases along the flow path. The stability of the temperature gradient in counterflow systems allows for greater overall heat dissipation compared to the parallel flow configuration.

Impact on Heatsink Performance and Cooling

Counterflow heatsinks enhance thermal performance by maintaining a higher temperature gradient between the heat source and the cooling medium, improving heat transfer efficiency. Parallel flow heatsinks offer uniform temperature distribution but may result in lower overall cooling performance compared to counterflow designs. Optimizing your heatsink choice depends on balancing heat dissipation demands with fluid flow dynamics to achieve maximum cooling efficiency.

Design Considerations for Each Flow Type

Counterflow heatsinks maximize thermal transfer by ensuring the cooling fluid flows opposite to the heat source, creating a greater temperature gradient and enhanced efficiency. Parallel flow designs offer simpler construction and uniform velocity distribution, reducing pressure drop but potentially limiting heat transfer effectiveness. When choosing Your heatsink, consider the complexity of the system, desired thermal performance, and space constraints to select the optimal flow configuration.

Applications and Typical Use Cases

Counterflow heatsinks are ideal for applications requiring efficient heat dissipation in confined spaces, such as aerospace electronics and compact industrial systems. Parallel flow heatsinks are commonly used in consumer electronics and automotive cooling, where larger surface areas and uniform temperature distribution are essential. Your choice depends on specific thermal management needs, balancing space constraints and performance requirements.

Pros and Cons of Counterflow and Parallel Flow Heatsinks

Counterflow heatsinks offer superior thermal efficiency by maintaining a larger temperature gradient along the heat exchange surface, making them ideal for high-performance cooling applications but often involve more complex design and manufacturing costs. Parallel flow heatsinks are simpler, more cost-effective, and provide uniform temperature distribution, though they generally exhibit lower heat transfer rates compared to counterflow designs. Evaluating your cooling requirements will help determine whether the enhanced thermal performance of counterflow or the simplicity and affordability of parallel flow heatsinks best suit your application.

Choosing the Right Flow Configuration for Your Needs

Selecting the appropriate heatsink flow configuration depends on the specific thermal management requirements and spatial constraints of your system. Counterflow heatsinks offer higher thermal efficiency by maintaining a greater temperature gradient between the fluid and heat source, ideal for applications needing maximum heat transfer. Parallel flow heatsinks provide simpler design and lower pressure drop, making them suitable for systems prioritizing ease of manufacturing and uniform temperature distribution.

Counterflow vs Parallel flow heatsink Infographic

libmatt.com

libmatt.com