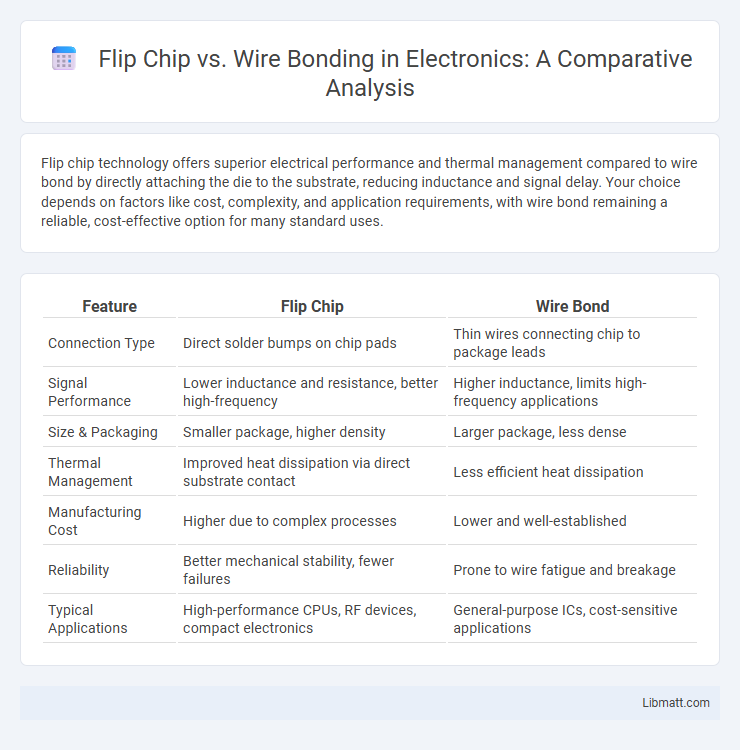

Flip chip technology offers superior electrical performance and thermal management compared to wire bond by directly attaching the die to the substrate, reducing inductance and signal delay. Your choice depends on factors like cost, complexity, and application requirements, with wire bond remaining a reliable, cost-effective option for many standard uses.

Table of Comparison

| Feature | Flip Chip | Wire Bond |

|---|---|---|

| Connection Type | Direct solder bumps on chip pads | Thin wires connecting chip to package leads |

| Signal Performance | Lower inductance and resistance, better high-frequency | Higher inductance, limits high-frequency applications |

| Size & Packaging | Smaller package, higher density | Larger package, less dense |

| Thermal Management | Improved heat dissipation via direct substrate contact | Less efficient heat dissipation |

| Manufacturing Cost | Higher due to complex processes | Lower and well-established |

| Reliability | Better mechanical stability, fewer failures | Prone to wire fatigue and breakage |

| Typical Applications | High-performance CPUs, RF devices, compact electronics | General-purpose ICs, cost-sensitive applications |

Introduction to Flip Chip and Wire Bond Technologies

Flip Chip and Wire Bond are two primary semiconductor packaging technologies used to connect integrated circuits to their substrates. Flip Chip involves directly mounting the chip face-down onto the substrate with solder bumps, providing shorter electrical paths and enhanced performance for high-frequency applications. Wire Bond connects the chip to the package using fine metal wires, offering cost-effective and reliable interconnections suited for many standard electronic devices.

Key Differences Between Flip Chip and Wire Bond

Flip chip technology mounts the semiconductor die face-down directly onto the substrate, providing shorter interconnects and improved electrical performance, while wire bond attaches the die face-up with fine wires connecting to the package leads. Flip chip offers higher input/output density and better thermal management compared to wire bond, which is simpler and more cost-effective for lower-performance applications. Your choice between flip chip and wire bond depends on factors like device size, performance requirements, and production cost constraints.

Historical Evolution of Packaging Methods

Wire bonding emerged in the 1950s as the primary method for connecting semiconductor chips to package leads due to its reliability and cost-effectiveness. Flip chip technology was introduced in the 1960s, offering shorter electrical paths and improved performance by directly mounting the chip face down on the substrate. Advances in materials and miniaturization trends have increasingly favored flip chip packaging for high-frequency and high-density applications, marking a significant evolution from traditional wire bond methods.

Flip Chip: Working Principle and Process

Flip Chip technology involves directly mounting the semiconductor die onto the substrate using tiny solder bumps, enabling electrical connections without the need for wire bonding. This process begins with bumping the die, flipping it face-down, and reflowing the solder bumps to create robust electrical and mechanical bonds. Your device benefits from improved performance, reduced signal inductance, and enhanced heat dissipation due to the shorter interconnects in Flip Chip assemblies.

Wire Bond: Working Principle and Process

Wire bond technology connects the semiconductor chip to its package using fine metal wires, typically gold or aluminum, to establish electrical pathways. The process involves precisely positioning and bonding these wires between the chip's bond pads and the lead frame through ultrasonic or thermosonic welding. Understanding the wire bond working principle is crucial for optimizing your device's electrical performance and reliability in semiconductor packaging.

Performance Comparison: Flip Chip vs Wire Bond

Flip chip technology offers superior electrical performance compared to wire bond due to shorter interconnect lengths and reduced parasitic inductance, enabling higher frequency operation and faster signal transmission. Wire bond is limited by longer and looped wire connections, resulting in increased resistance, inductance, and signal delay that can impact high-speed applications. Flip chip's enhanced thermal management also improves reliability and performance under demanding conditions, making it the preferred choice for advanced semiconductor packaging.

Cost Analysis and Market Trends

Flip chip technology typically incurs higher initial costs due to advanced packaging and underfill materials but offers superior electrical performance and miniaturization benefits, making it ideal for high-end applications. Wire bond remains cost-effective for mass production with simpler manufacturing processes, appealing to markets requiring lower budget packaging such as automotive and consumer electronics. Market trends indicate increasing adoption of flip chip in 5G, AI, and high-performance computing sectors driven by demand for greater speed and integration, while wire bond maintains steady growth in traditional sectors valuing cost efficiency.

Application Areas: When to Use Flip Chip or Wire Bond

Flip Chip technology is ideal for high-performance applications requiring superior electrical and thermal conductivity, such as in advanced CPUs, GPUs, and RF devices, where miniaturization and enhanced signal integrity are critical. Wire Bonding remains a cost-effective choice for medium to low-frequency applications, including automotive electronics, consumer devices, and power modules, where design flexibility and lower production costs are priorities. Your decision should consider factors like device complexity, thermal management needs, and budget constraints to select the most suitable interconnection method.

Reliability and Manufacturing Challenges

Flip chip technology offers superior reliability compared to wire bonding by providing shorter interconnect paths, which reduce signal inductance and improve electrical performance, especially in high-frequency applications. Manufacturing challenges for flip chips include precise alignment and complex underfill processes to prevent thermal stress and warpage, whereas wire bonding is easier to implement but more susceptible to mechanical damage and signal degradation due to longer bond wires. The choice between flip chip and wire bond depends on balancing reliability requirements, production complexity, and cost constraints in semiconductor packaging.

Future Outlook for Flip Chip and Wire Bond Packaging

Flip chip packaging offers significant advantages for future electronics with its superior electrical performance, higher I/O density, and enhanced heat dissipation, making it ideal for advanced applications such as 5G, AI, and high-speed computing. Wire bond technology remains cost-effective and reliable for lower complexity and less demanding applications, ensuring its continued relevance in consumer electronics and automotive industries. Your choice between flip chip and wire bond packaging should consider long-term scalability, thermal management needs, and integration requirements to optimize device performance.

Flip Chip vs Wire Bond Infographic

libmatt.com

libmatt.com