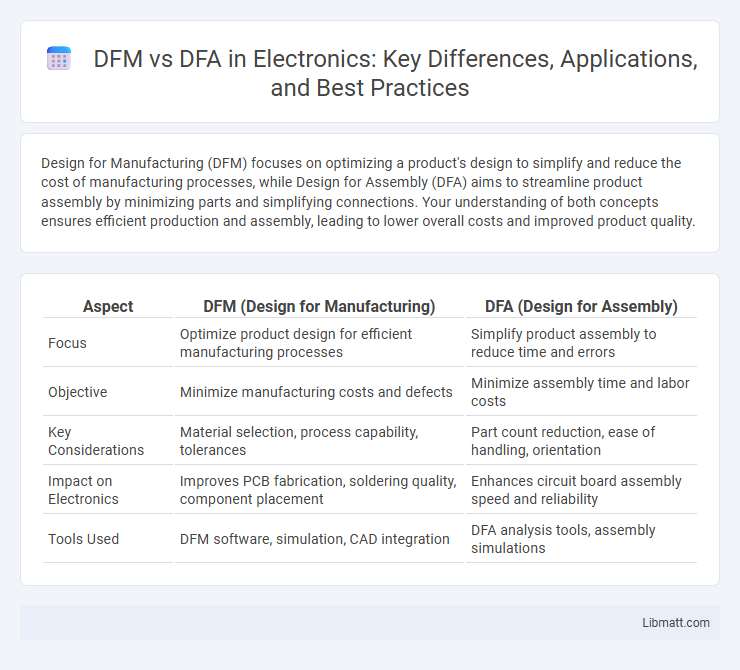

Design for Manufacturing (DFM) focuses on optimizing a product's design to simplify and reduce the cost of manufacturing processes, while Design for Assembly (DFA) aims to streamline product assembly by minimizing parts and simplifying connections. Your understanding of both concepts ensures efficient production and assembly, leading to lower overall costs and improved product quality.

Table of Comparison

| Aspect | DFM (Design for Manufacturing) | DFA (Design for Assembly) |

|---|---|---|

| Focus | Optimize product design for efficient manufacturing processes | Simplify product assembly to reduce time and errors |

| Objective | Minimize manufacturing costs and defects | Minimize assembly time and labor costs |

| Key Considerations | Material selection, process capability, tolerances | Part count reduction, ease of handling, orientation |

| Impact on Electronics | Improves PCB fabrication, soldering quality, component placement | Enhances circuit board assembly speed and reliability |

| Tools Used | DFM software, simulation, CAD integration | DFA analysis tools, assembly simulations |

Understanding DFM and DFA: Definitions and Scope

Design for Manufacturing (DFM) focuses on optimizing product designs to simplify production processes, reduce costs, and improve quality. Design for Assembly (DFA) targets minimizing the complexity and time required to assemble components, enhancing efficiency in the assembly line. Understanding both DFM and DFA ensures your product is engineered for seamless manufacturing and assembly, leading to streamlined production and lower overall expenses.

Key Principles of Design for Manufacturability (DFM)

Design for Manufacturability (DFM) emphasizes simplifying product designs to reduce manufacturing complexity, aiming to lower production costs and improve quality. Key principles include minimizing part counts, standardizing components, and designing features that facilitate efficient assembly and testing. Your product benefits from smoother production processes and fewer defects when these principles are carefully integrated into the design phase.

Core Concepts of Design for Assembly (DFA)

Design for Assembly (DFA) emphasizes minimizing the number of parts to reduce assembly time and cost, focusing on simplifying product structure and enhancing ease of handling during assembly. Core concepts include modular design, using self-locating and self-fastening features, and standardizing components to streamline the assembly process. DFA integrates considerations such as part accessibility, orientation, and insertion direction, ensuring efficient and error-free assembly workflows.

Objectives: DFM vs DFA

Design for Manufacturing (DFM) aims to simplify product design to reduce production costs, improve manufacturability, and ensure quality by minimizing complexity and using standard components. In contrast, Design for Assembly (DFA) focuses on reducing assembly time and labor by minimizing the number of parts, simplifying assembly operations, and optimizing part handling. Both methodologies prioritize cost reduction and efficiency but target distinct stages of the product development process: DFM optimizes manufacturing processes, while DFA streamlines assembly procedures.

Benefits of Applying DFM and DFA

Applying Design for Manufacturing (DFM) reduces production costs and accelerates time-to-market by optimizing design processes for manufacturability. Design for Assembly (DFA) improves product quality and assembly efficiency by minimizing parts and simplifying assembly steps. Together, DFM and DFA enhance overall product reliability, lower defect rates, and increase production scalability.

Challenges and Limitations in DFM and DFA

Design for Manufacturing (DFM) faces challenges such as limited flexibility in accommodating design changes late in the process and managing complex tolerances that can increase production costs. Design for Assembly (DFA) often struggles with balancing ease of assembly against functional or aesthetic requirements, which can lead to compromises in product performance or increased part count. Your ability to optimize both DFM and DFA is critical to minimizing production delays and ensuring cost-effective, high-quality manufacturing outcomes.

Tools and Techniques for DFM and DFA Implementation

DFM (Design for Manufacturing) leverages simulation software, CAD integration, and tolerance analysis tools to optimize product designs for cost-effective production. DFA (Design for Assembly) employs methods like assembly sequence analysis and ergonomic evaluation tools to simplify product assembly and reduce labor costs. Your use of these specialized tools enhances efficiency by streamlining both manufacturing processes and assembly workflows.

DFM and DFA in Product Development Lifecycle

DFM (Design for Manufacturability) and DFA (Design for Assembly) are critical methodologies integrated into the product development lifecycle to enhance production efficiency and reduce costs. DFM focuses on simplifying manufacturing processes, optimizing material selection, and minimizing production steps, while DFA targets reducing assembly time and complexity by designing products for easier and quicker assembly. Implementing DFM and DFA early in the design phase accelerates time-to-market, improves product quality, and ensures smoother transition from prototype to mass production.

Case Studies: DFM vs DFA Impact

Case studies highlight that Design for Manufacturing (DFM) and Design for Assembly (DFA) significantly impact production efficiency and cost reduction. Companies implementing DFM achieve up to 30% lower manufacturing defects, while those adopting DFA report assembly time decreases by 25-40%, enhancing overall product quality. Real-world analyses underscore the complementary nature of DFM and DFA, where integrated application drives optimal design outcomes and operational performance.

Choosing Between DFM and DFA for Optimal Design

Choosing between Design for Manufacturing (DFM) and Design for Assembly (DFA) depends on the specific product goals and production challenges, with DFM emphasizing manufacturability and cost-effective fabrication, while DFA targets simplifying the assembly process to reduce labor and errors. An optimal design balances both approaches by integrating manufacturing constraints and assembly efficiencies early in the development cycle, thereby minimizing production costs and enhancing product quality. Leveraging CAD tools and cross-functional teams improves decision-making by identifying trade-offs between manufacturing complexities and assembly time.

DFM vs DFA Infographic

libmatt.com

libmatt.com