Silver solder offers superior conductivity and strength compared to lead-free solder, making it ideal for high-performance electrical and plumbing applications. Your choice depends on the specific requirements, as lead-free solder provides a safer, more environmentally friendly option without the toxicity risks associated with lead.

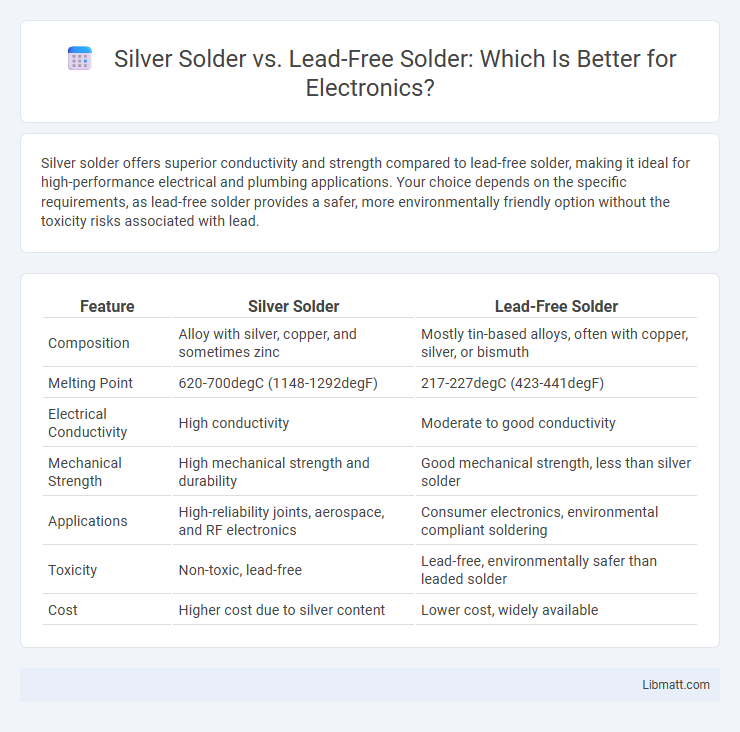

Table of Comparison

| Feature | Silver Solder | Lead-Free Solder |

|---|---|---|

| Composition | Alloy with silver, copper, and sometimes zinc | Mostly tin-based alloys, often with copper, silver, or bismuth |

| Melting Point | 620-700degC (1148-1292degF) | 217-227degC (423-441degF) |

| Electrical Conductivity | High conductivity | Moderate to good conductivity |

| Mechanical Strength | High mechanical strength and durability | Good mechanical strength, less than silver solder |

| Applications | High-reliability joints, aerospace, and RF electronics | Consumer electronics, environmental compliant soldering |

| Toxicity | Non-toxic, lead-free | Lead-free, environmentally safer than leaded solder |

| Cost | Higher cost due to silver content | Lower cost, widely available |

Introduction to Solder Types

Silver solder offers superior thermal conductivity and stronger joints compared to lead-free solder, making it ideal for high-performance applications. Lead-free solder, often composed of tin, copper, and other metals, is favored for its environmental safety and compliance with RoHS standards. Your choice between silver solder and lead-free solder should consider factors like melting point, mechanical strength, and regulatory requirements.

What is Silver Solder?

Silver solder is a type of brazing alloy containing a high percentage of silver, usually between 20% and 40%, mixed with other metals like copper and zinc to enhance strength and corrosion resistance. It melts at a higher temperature than lead-free solder, typically around 600-800degC, making it ideal for applications requiring durable, high-strength joints such as jewelry making, plumbing, and electronics. The silver content provides superior thermal and electrical conductivity compared to lead-free solder, which is primarily composed of tin and other metals like copper and silver but in lower quantities.

What is Lead-Free Solder?

Lead-free solder is an alloy primarily composed of tin combined with metals such as silver, copper, or bismuth, designed to eliminate lead content for environmental and health safety. It meets strict regulations like the Restriction of Hazardous Substances Directive (RoHS) and is commonly used in electronics manufacturing to reduce toxic exposure. Lead-free solder typically has a higher melting point than traditional leaded solder, requiring adjusted temperature settings during the soldering process.

Key Differences Between Silver and Lead-Free Solder

Silver solder contains a higher percentage of silver, typically 2-30%, providing superior thermal conductivity and mechanical strength compared to lead-free solder, which often consists of tin, copper, and silver in smaller quantities. Lead-free solder complies with environmental regulations such as RoHS by eliminating lead content, reducing toxicity and improving safety in electronic assemblies. The melting point of silver solder is generally higher, around 620-780degC, whereas lead-free solder melts at approximately 217-227degC, impacting compatibility with temperature-sensitive components.

Melting Point Comparison

Silver solder typically has a melting point range between 620degC and 780degC, making it ideal for high-temperature applications requiring strong, durable joints. Lead-free solder melts at a lower temperature, usually between 217degC and 227degC, offering safer use with reduced health risks and compliance with environmental regulations. Your choice depends on the required operating temperature and safety considerations of your project.

Electrical Conductivity and Performance

Silver solder offers superior electrical conductivity compared to lead-free solder, enhancing performance in high-precision electronic applications. Its lower electrical resistance ensures efficient current flow, making it ideal for sensitive circuits and components. When optimizing Your devices for durability and conductivity, silver solder provides a reliable connection that surpasses the capabilities of most lead-free alternatives.

Health and Environmental Impact

Silver solder contains silver along with other metals, often including lead, which poses significant health risks due to lead toxicity and environmental contamination during disposal. Lead-free solder, typically composed of tin, copper, and other non-toxic metals, reduces health hazards and environmental damage by eliminating lead, making it a safer alternative for both personal health and ecological sustainability. Regulatory standards increasingly favor lead-free solder to minimize lead exposure and promote environmentally responsible manufacturing practices.

Application Suitability

Silver solder excels in high-strength and high-temperature applications such as jewelry making, plumbing, and HVAC systems due to its superior mechanical properties and excellent corrosion resistance. Lead-free solder is preferred for electronic circuit boards and electrical connections where environmental and health safety standards mandate the absence of lead content. Your choice depends on whether you prioritize durability and thermal performance or compliance with modern, eco-friendly regulations.

Cost Considerations

Silver solder typically incurs higher costs due to its precious metal content and superior thermal conductivity, making it ideal for high-performance applications requiring strong, reliable joints. Lead-free solder, often composed of tin, copper, and silver alloys without lead, offers a more economical option aligned with environmental regulations and consumer safety standards. Businesses must weigh the initial investment of silver solder against the cost savings and regulatory compliance benefits of lead-free alternatives in their production processes.

Choosing the Right Solder for Your Project

Choosing the right solder for your project involves considering factors such as melting point, strength, and toxicity. Silver solder, containing silver alloy, offers higher strength and better conductivity, making it ideal for high-stress or electrical connections, while lead-free solder, typically composed of tin, copper, and silver or other metals, is preferred for its environmental safety and compliance with RoHS standards. Evaluate project requirements like temperature tolerance, joint durability, and regulatory compliance to determine whether silver solder or lead-free solder is the optimal choice.

Silver Solder vs Lead-Free Solder Infographic

libmatt.com

libmatt.com