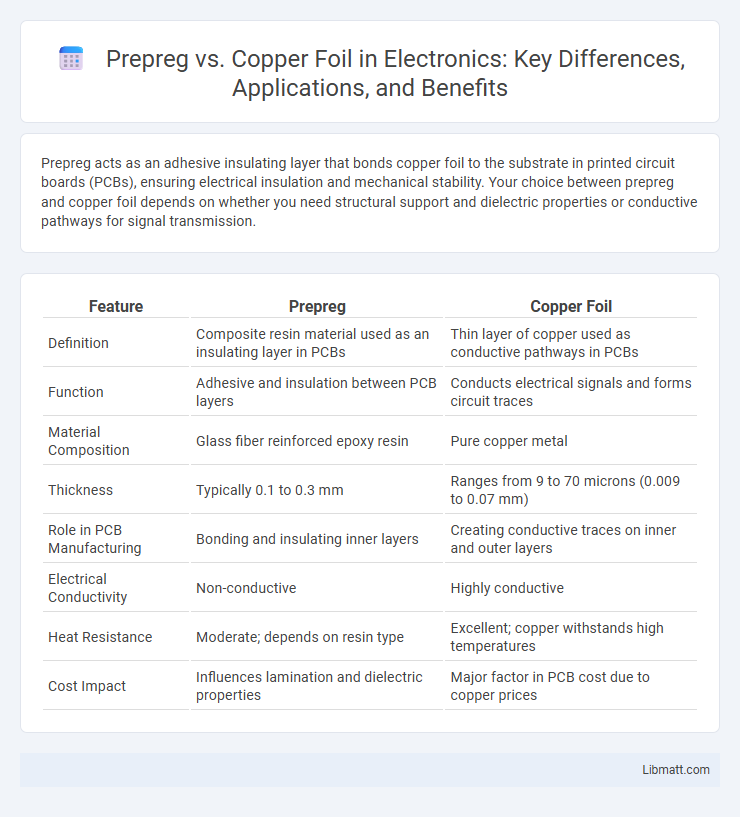

Prepreg acts as an adhesive insulating layer that bonds copper foil to the substrate in printed circuit boards (PCBs), ensuring electrical insulation and mechanical stability. Your choice between prepreg and copper foil depends on whether you need structural support and dielectric properties or conductive pathways for signal transmission.

Table of Comparison

| Feature | Prepreg | Copper Foil |

|---|---|---|

| Definition | Composite resin material used as an insulating layer in PCBs | Thin layer of copper used as conductive pathways in PCBs |

| Function | Adhesive and insulation between PCB layers | Conducts electrical signals and forms circuit traces |

| Material Composition | Glass fiber reinforced epoxy resin | Pure copper metal |

| Thickness | Typically 0.1 to 0.3 mm | Ranges from 9 to 70 microns (0.009 to 0.07 mm) |

| Role in PCB Manufacturing | Bonding and insulating inner layers | Creating conductive traces on inner and outer layers |

| Electrical Conductivity | Non-conductive | Highly conductive |

| Heat Resistance | Moderate; depends on resin type | Excellent; copper withstands high temperatures |

| Cost Impact | Influences lamination and dielectric properties | Major factor in PCB cost due to copper prices |

Introduction to Prepreg and Copper Foil

Prepreg is a composite material consisting of reinforcing fibers pre-impregnated with resin, commonly used in printed circuit boards (PCBs) for insulation and bonding layers. Copper foil, a thin sheet of copper, serves as the conductive layer in PCBs, enabling electrical signal transmission and circuit pathways. The interplay between prepreg and copper foil is essential for the structural integrity and electrical performance of multilayer PCBs.

Composition and Material Properties

Prepreg consists of woven fiberglass fabric impregnated with a partially cured epoxy resin, providing excellent insulation and mechanical stability in PCB manufacturing. Copper foil is a thin sheet of high-purity copper, known for its superior electrical conductivity and flexibility, essential for circuit pathways. The combination of prepreg's dielectric strength and copper foil's conductive properties enables the creation of multilayer printed circuit boards with reliable electrical performance and structural integrity.

Manufacturing Processes

Prepreg is produced by impregnating woven glass fibers with a partially cured epoxy resin, which provides excellent insulation and bonding properties during PCB lamination, while copper foil is manufactured through electro-deposition and rolled annealing to create a thin, conductive layer. The prepreg's resin content and weave type are controlled precisely to ensure mechanical strength and dielectric performance, whereas copper foil thickness and surface treatment directly impact conductivity and adhesion to the substrate. Understanding these manufacturing processes helps optimize your PCB design by balancing electrical performance and mechanical integrity.

Key Applications in PCB Fabrication

Prepreg serves as the insulating layer and adhesive matrix in multilayer PCB fabrication, providing electrical isolation and mechanical strength between copper foil layers. Copper foil acts as the conductive material that forms the circuit pathways and signal traces essential for electrical connectivity in PCBs. Together, prepreg and copper foil enable the creation of high-performance printed circuit boards used in telecommunications, consumer electronics, and automotive industries.

Electrical Performance Comparison

Prepreg typically offers superior insulation properties and dielectric strength compared to copper foil, making it essential for high-frequency signal integrity and reduced signal loss in your PCB design. Copper foil excels in electrical conductivity, enabling efficient current flow and minimizing resistance, which is crucial for power delivery and grounding layers. Balancing the dielectric constant of prepreg with the conductivity of copper foil optimizes overall electrical performance in multilayer circuit boards.

Mechanical Strength and Durability

Prepreg offers superior mechanical strength due to its composite resin matrix, providing enhanced impact resistance and durability in multilayer PCB construction compared to copper foil alone. Copper foil, while essential for electrical conductivity, is more prone to mechanical wear and tear without the structural reinforcement supplied by prepreg. Your choice of materials directly influences the longevity and robustness of the final electronic device, with prepreg ensuring greater structural integrity under mechanical stress.

Cost Considerations

Prepreg typically incurs higher costs due to its specialized composite resin and fabric materials, contributing to better insulation and mechanical stability in PCB manufacturing. Copper foil, while generally less expensive, varies in price based on thickness and quality, impacting the overall cost of conductive layers. Your choice between prepreg and copper foil directly affects the balance between material expenses and performance requirements in electronic assembly.

Environmental and Thermal Stability

Prepreg offers superior environmental resistance due to its engineered resin systems that maintain structural integrity under high humidity and chemical exposure, outperforming copper foil's susceptibility to corrosion. Thermal stability in prepreg materials ensures consistent performance through repeated heat cycles, vital for maintaining signal integrity in multilayer PCBs. Your choice should balance these factors, as prepreg provides enhanced durability where thermal and environmental stresses are significant.

Challenges and Limitations

Prepreg faces challenges such as limited resin flow control and potential void formation during lamination, which can affect PCB reliability. Copper foil exhibits limitations in thickness uniformity and adhesion strength, impacting electrical performance and circuit durability. Both materials require precise processing to overcome these issues and maintain high-quality PCB fabrication standards.

Choosing Between Prepreg and Copper Foil

Choosing between prepreg and copper foil depends on the specific requirements of your printed circuit board (PCB) design, as prepreg serves as the insulating substrate material while copper foil acts as the conductive layer. Prepreg provides mechanical strength and dielectric properties essential for multilayer PCBs, whereas copper foil ensures efficient electrical conductivity and signal integrity. Your decision should consider factors like electrical performance, layer count, and thermal management to optimize PCB functionality.

Prepreg vs Copper Foil Infographic

libmatt.com

libmatt.com