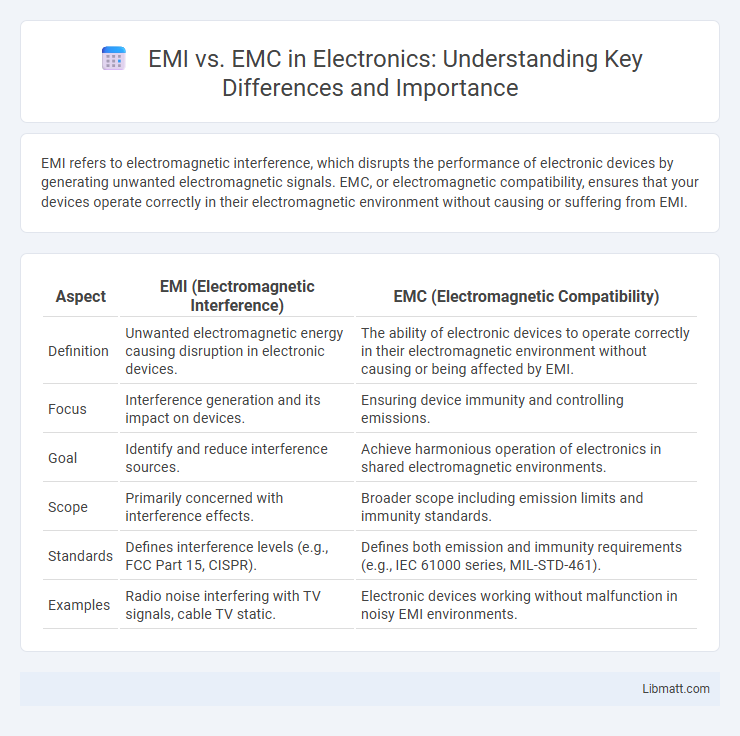

EMI refers to electromagnetic interference, which disrupts the performance of electronic devices by generating unwanted electromagnetic signals. EMC, or electromagnetic compatibility, ensures that your devices operate correctly in their electromagnetic environment without causing or suffering from EMI.

Table of Comparison

| Aspect | EMI (Electromagnetic Interference) | EMC (Electromagnetic Compatibility) |

|---|---|---|

| Definition | Unwanted electromagnetic energy causing disruption in electronic devices. | The ability of electronic devices to operate correctly in their electromagnetic environment without causing or being affected by EMI. |

| Focus | Interference generation and its impact on devices. | Ensuring device immunity and controlling emissions. |

| Goal | Identify and reduce interference sources. | Achieve harmonious operation of electronics in shared electromagnetic environments. |

| Scope | Primarily concerned with interference effects. | Broader scope including emission limits and immunity standards. |

| Standards | Defines interference levels (e.g., FCC Part 15, CISPR). | Defines both emission and immunity requirements (e.g., IEC 61000 series, MIL-STD-461). |

| Examples | Radio noise interfering with TV signals, cable TV static. | Electronic devices working without malfunction in noisy EMI environments. |

Introduction to EMI and EMC

Electromagnetic Interference (EMI) refers to the disturbance generated by an external electromagnetic field affecting electronic devices' performance. Electromagnetic Compatibility (EMC) ensures that your electronic equipment operates without causing or suffering from EMI. Understanding EMI and EMC is crucial for designing systems that maintain functionality and reliability in electrically noisy environments.

Understanding Electromagnetic Interference (EMI)

Electromagnetic Interference (EMI) refers to the disruption caused by unwanted electromagnetic signals that degrade the performance of electronic devices and communication systems. Understanding EMI involves recognizing sources such as power lines, radio transmissions, and electronic circuits that emit noise, affecting your equipment's functionality and reliability. Effective EMI management ensures improved signal integrity and compliance with regulatory standards for electromagnetic compatibility (EMC).

Defining Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) refers to the ability of electronic devices to operate without causing or being affected by electromagnetic interference (EMI). EMC ensures that equipment functions correctly in its electromagnetic environment by limiting both emissions and susceptibility to disruptive electromagnetic disturbances. Compliance with EMC standards is critical for minimizing EMI-related failures and maintaining reliable performance in interconnected electronic systems.

Key Differences Between EMI and EMC

Electromagnetic Interference (EMI) refers to the disturbance generated by external electromagnetic fields that disrupt electrical device performance, while Electromagnetic Compatibility (EMC) denotes a device's ability to operate without causing or suffering from such interference. EMI focuses on the source and effects of unwanted electromagnetic noise, whereas EMC encompasses both emission control and immunity requirements to ensure harmonious device operation. Effective EMI mitigation techniques and EMC standards are critical for reducing signal degradation and ensuring reliable electronic system functionality.

Sources and Types of EMI

Electromagnetic Interference (EMI) originates from natural sources such as lightning, solar flares, and cosmic noise, as well as man-made sources including power lines, radio transmitters, and electronic devices with switching circuits. Different types of EMI include conducted interference, which travels along conductive paths like cables and power lines, and radiated interference that propagates through the air as electromagnetic waves. Understanding these sources and types of EMI is essential for implementing effective Electromagnetic Compatibility (EMC) measures to ensure reliable operation of electronic equipment.

Importance of EMC in Electronic Design

Electromagnetic Compatibility (EMC) is crucial in electronic design to ensure devices operate without causing or succumbing to electromagnetic interference (EMI), which can disrupt functionality and degrade performance. Effective EMC practices minimize signal disruptions, enhance device reliability, and comply with regulatory standards such as CISPR and FCC. Prioritizing EMC in design leads to improved product safety, reduced warranty costs, and seamless integration within diverse electromagnetic environments.

EMI Reduction Techniques

EMI reduction techniques primarily involve shielding, grounding, and filtering to minimize electromagnetic interference that can disrupt electronic device performance. Proper shielding uses conductive or magnetic materials to block or absorb unwanted emissions, while effective grounding provides a reference point that dissipates stray signals safely. Filtering incorporates components like capacitors and inductors to suppress noise by allowing desired signals to pass while attenuating interference frequencies.

EMC Compliance Standards and Regulations

EMC compliance standards and regulations ensure electronic devices operate without causing or suffering from electromagnetic interference (EMI), crucial for maintaining device functionality and safety. Key standards include CISPR 22 for information technology equipment, MIL-STD-461 for military applications, and IEC 61000 series addressing immunity and emission limits. Regulatory bodies like the FCC in the United States, the European Union's CE marking, and Japan's VCCI enforce these standards to guarantee global interoperability and reduce electromagnetic disturbances.

Testing Methods for EMI and EMC

Testing methods for EMI and EMC involve comprehensive procedures such as radiated and conducted emission measurements to evaluate unwanted electromagnetic interference from your device. Immunity tests assess how well the product withstands external electromagnetic disturbances, ensuring compliance with industry standards like CISPR and IEC. Advanced testing facilities use anechoic chambers and spectrum analyzers to accurately detect and mitigate EMI/EMC issues in electronics.

Future Trends in EMI and EMC Management

Future trends in EMI and EMC management emphasize intelligent materials with self-healing properties and adaptive shielding technologies that dynamically respond to electromagnetic interference. The integration of AI-driven monitoring and predictive analytics enables real-time detection and mitigation of EMI, improving overall system resilience. Advancements in nanotechnology and metamaterials are also poised to revolutionize EMC solutions by providing ultra-compact, highly efficient components for next-generation electronic devices.

EMI vs EMC Infographic

libmatt.com

libmatt.com