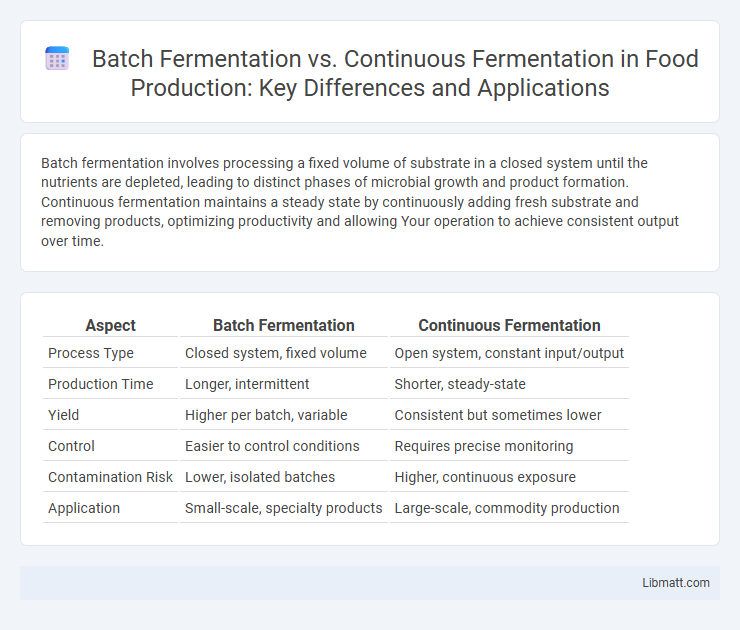

Batch fermentation involves processing a fixed volume of substrate in a closed system until the nutrients are depleted, leading to distinct phases of microbial growth and product formation. Continuous fermentation maintains a steady state by continuously adding fresh substrate and removing products, optimizing productivity and allowing Your operation to achieve consistent output over time.

Table of Comparison

| Aspect | Batch Fermentation | Continuous Fermentation |

|---|---|---|

| Process Type | Closed system, fixed volume | Open system, constant input/output |

| Production Time | Longer, intermittent | Shorter, steady-state |

| Yield | Higher per batch, variable | Consistent but sometimes lower |

| Control | Easier to control conditions | Requires precise monitoring |

| Contamination Risk | Lower, isolated batches | Higher, continuous exposure |

| Application | Small-scale, specialty products | Large-scale, commodity production |

Introduction to Batch and Continuous Fermentation

Batch fermentation involves processing microorganisms in a closed system where all nutrients are added at the start, resulting in distinct phases of microbial growth and product formation. Continuous fermentation operates with a constant input of fresh medium and simultaneous removal of culture broth, maintaining microorganisms in a steady state for prolonged production. Key differences between batch and continuous fermentation impact productivity, scalability, and process control in industrial biotechnology applications.

Fundamental Principles of Fermentation Processes

Batch fermentation operates on a closed system where substrates are added at the beginning and products harvested at the end, emphasizing distinct growth phases of microorganisms. Continuous fermentation uses an open system with constant input of substrates and simultaneous removal of products, maintaining cells in a steady-state exponential growth phase. The fundamental principle distinguishing these processes lies in substrate availability and microbial growth dynamics, impacting productivity and process control strategies.

Key Differences Between Batch and Continuous Fermentation

Batch fermentation involves processing a fixed volume of substrate in a single run, leading to distinct phases of microbial growth and product formation, whereas continuous fermentation maintains a steady-state by constantly adding fresh substrate and removing culture. Batch fermentation offers ease of control and flexibility, ideal for small-scale or variable products, while continuous fermentation enhances productivity and consistency suited for large-scale industrial applications. Your choice depends on factors like production scale, process control, and product specificity.

Advantages of Batch Fermentation

Batch fermentation offers precise control over microbial growth phases and substrate concentrations, reducing contamination risk and allowing high product quality consistency. This method is ideal for producing high-value products where process flexibility and easy monitoring are crucial. You benefit from simpler operation protocols and enhanced product safety due to the closed environment throughout the fermentation cycle.

Limitations of Batch Fermentation

Batch fermentation is limited by substrate depletion and product inhibition, causing variable yields and reduced productivity over time. The discontinuous process requires downtime for cleaning and loading, increasing operational costs and reducing overall efficiency. Scale-up challenges arise due to inconsistent conditions throughout the batch, impacting reproducibility and product quality.

Advantages of Continuous Fermentation

Continuous fermentation offers significant advantages such as higher productivity and consistent product quality by maintaining steady-state conditions. You benefit from reduced downtime since the process runs uninterrupted, leading to better resource utilization and lower labor costs. This method also minimizes contamination risks and allows for real-time process monitoring and control, enhancing overall efficiency.

Challenges of Continuous Fermentation

Continuous fermentation faces challenges such as maintaining consistent microbial activity and preventing contamination over extended periods. Reactor design must ensure optimal conditions for steady-state operation, which can be complex and costly to implement. Your process stability may also be affected by nutrient depletion or accumulation of inhibitory by-products, requiring careful monitoring and control systems.

Industrial Applications and Case Studies

Batch fermentation is commonly utilized in industries producing specialty products like antibiotics and enzymes due to its controlled environment and ability to handle small-scale, high-value production. Continuous fermentation is preferred for large-scale industrial applications such as bioethanol and organic acid production, offering higher productivity and consistent product quality through steady-state operation. Your choice depends on production scale, product type, and economic considerations, with case studies highlighting continuous fermentation's efficiency in ethanol plants and batch fermentation's flexibility in pharmaceutical manufacturing.

Factors Affecting Choice of Fermentation Method

The choice between batch fermentation and continuous fermentation depends on factors such as production scale, microorganism stability, and process control requirements. Batch fermentation is preferable for smaller-scale production or products requiring strict quality and consistency control, while continuous fermentation excels in large-scale operations demanding higher productivity and efficiency. Your decision should also consider substrate availability, contamination risk, and operational complexity to optimize yield and cost-effectiveness.

Future Trends in Fermentation Technology

Future trends in fermentation technology emphasize continuous fermentation due to its efficiency in maintaining steady-state conditions and higher productivity levels compared to batch fermentation. Innovations in real-time monitoring, automation, and process control are making continuous systems more adaptable and scalable for industrial applications. You can expect these advancements to drive significant improvements in sustainability and cost-effectiveness in bioproduction.

batch fermentation vs continuous fermentation Infographic

libmatt.com

libmatt.com