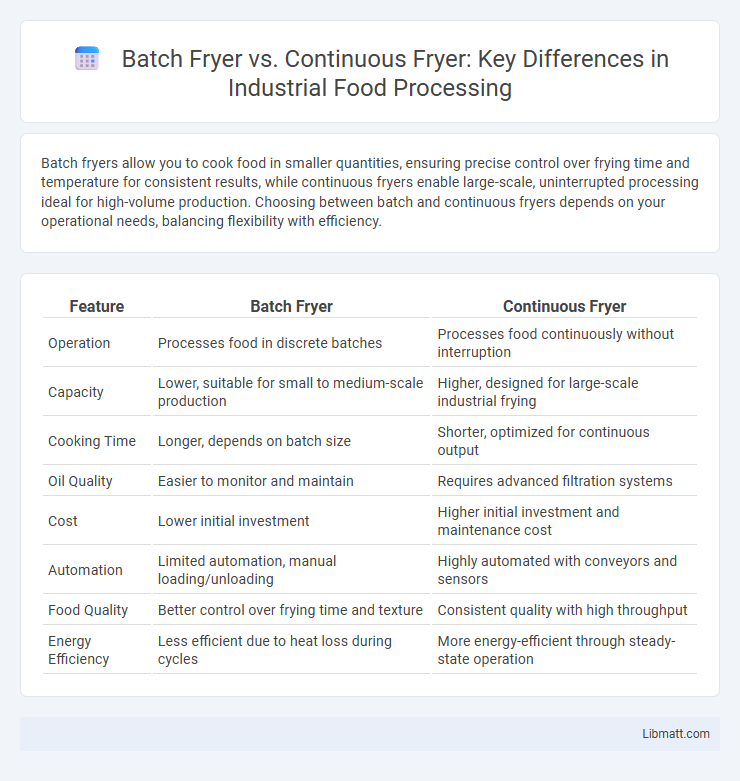

Batch fryers allow you to cook food in smaller quantities, ensuring precise control over frying time and temperature for consistent results, while continuous fryers enable large-scale, uninterrupted processing ideal for high-volume production. Choosing between batch and continuous fryers depends on your operational needs, balancing flexibility with efficiency.

Table of Comparison

| Feature | Batch Fryer | Continuous Fryer |

|---|---|---|

| Operation | Processes food in discrete batches | Processes food continuously without interruption |

| Capacity | Lower, suitable for small to medium-scale production | Higher, designed for large-scale industrial frying |

| Cooking Time | Longer, depends on batch size | Shorter, optimized for continuous output |

| Oil Quality | Easier to monitor and maintain | Requires advanced filtration systems |

| Cost | Lower initial investment | Higher initial investment and maintenance cost |

| Automation | Limited automation, manual loading/unloading | Highly automated with conveyors and sensors |

| Food Quality | Better control over frying time and texture | Consistent quality with high throughput |

| Energy Efficiency | Less efficient due to heat loss during cycles | More energy-efficient through steady-state operation |

Introduction to Industrial Fryers

Industrial fryers include batch fryers and continuous fryers, both essential in high-volume food production. Batch fryers handle fixed quantities of food, allowing precise control over cooking time and temperature, ideal for varied products or smaller batches. Continuous fryers operate with a steady flow of food through the frying oil, maximizing efficiency for large-scale, uniform processing in industries like snack manufacturing.

Overview of Batch Fryer Technology

Batch fryer technology operates by frying food in discrete quantities, using a single chamber heated to a specific temperature and allowing precise control over cooking time and oil absorption. This method ensures consistent quality for smaller production volumes, making it ideal for artisanal or small-scale food manufacturing. Batch fryers typically require manual loading and unloading, resulting in intermittent operation compared to continuous fryer systems that enable nonstop processing.

Understanding Continuous Fryer Systems

Continuous fryer systems offer increased production efficiency by allowing constant input and output of food products, significantly reducing downtime compared to batch fryers. These systems maintain consistent oil temperature and frying times, ensuring uniform product quality and higher throughput essential in large-scale food manufacturing. If your operation demands high volume and consistent output, investing in a continuous fryer system can optimize productivity and product consistency.

Key Differences Between Batch and Continuous Fryers

Batch fryers process food in discrete quantities, allowing precise control over cooking time and temperature for varied product types. Continuous fryers operate with an ongoing flow of product, optimizing efficiency and consistency for large-scale production. The choice between batch and continuous fryers depends on production volume, product variety, and operational flexibility requirements.

Production Capacity and Efficiency

Batch fryers offer lower production capacity, typically suitable for small to medium-scale operations, while continuous fryers provide high throughput, ideal for large-scale industrial frying. Continuous fryers maximize efficiency by maintaining constant oil temperature and minimizing downtime, resulting in consistent product quality and faster processing times. Your choice depends on production volume requirements and whether efficiency or flexibility is the priority.

Product Quality and Consistency

Batch fryers offer greater control over individual cooking cycles, ensuring precise frying times and temperatures that enhance product quality and achieve a consistent texture and flavor. Continuous fryers maintain uniform heat and oil circulation, enabling steady production with minimal quality variation ideal for large-scale operations. Your choice depends on balancing the need for consistent, high-quality output with production volume and efficiency requirements.

Energy Consumption and Operational Costs

Batch fryers generally consume more energy per unit of product due to frequent heating and cooling cycles, increasing operational costs in high-volume environments. Continuous fryers maintain consistent temperatures, improving energy efficiency and reducing fuel consumption through steady-state operation. Operational costs for continuous fryers are typically lower, driven by reduced energy usage and higher throughput compared to batch frying methods.

Maintenance Requirements and Downtime

Batch fryers require frequent cleaning and maintenance between cycles, leading to regular downtime to ensure food quality and equipment longevity. Continuous fryers have more complex systems but allow for ongoing operation with scheduled maintenance intervals, minimizing overall downtime. Your maintenance strategy should consider the trade-off between batch fryers' shorter use periods and continuous fryers' extended running time to optimize productivity.

Application Suitability by Product Type

Batch fryers excel in handling small to medium volumes and are ideal for products requiring precise cooking times, such as chips, nuggets, and specialty snacks. Continuous fryers are better suited for large-scale operations processing uniform products like potato fries and tortilla chips, ensuring consistent quality and high throughput. Your choice depends on product type, production volume, and desired control over cooking parameters.

Choosing the Right Fryer for Your Food Processing Needs

Selecting the right fryer depends on your production volume and product consistency requirements. Batch fryers offer flexibility for small to medium-sized batches with easier quality control, while continuous fryers provide efficiency and uniform cooking for large-scale food processing. Your choice should balance throughput, space, and product type to optimize frying performance and operational costs.

Batch Fryer vs Continuous Fryer Infographic

libmatt.com

libmatt.com