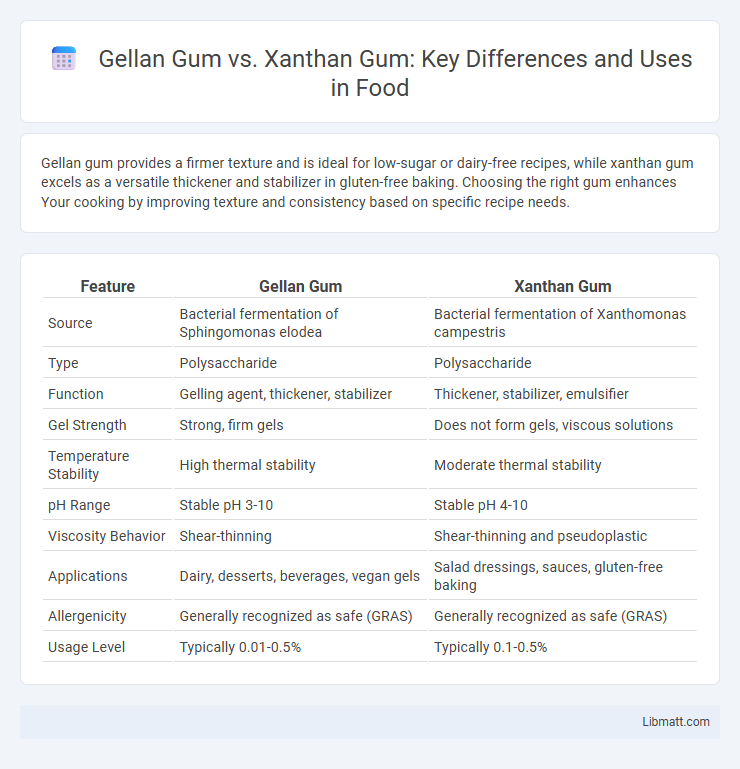

Gellan gum provides a firmer texture and is ideal for low-sugar or dairy-free recipes, while xanthan gum excels as a versatile thickener and stabilizer in gluten-free baking. Choosing the right gum enhances Your cooking by improving texture and consistency based on specific recipe needs.

Table of Comparison

| Feature | Gellan Gum | Xanthan Gum |

|---|---|---|

| Source | Bacterial fermentation of Sphingomonas elodea | Bacterial fermentation of Xanthomonas campestris |

| Type | Polysaccharide | Polysaccharide |

| Function | Gelling agent, thickener, stabilizer | Thickener, stabilizer, emulsifier |

| Gel Strength | Strong, firm gels | Does not form gels, viscous solutions |

| Temperature Stability | High thermal stability | Moderate thermal stability |

| pH Range | Stable pH 3-10 | Stable pH 4-10 |

| Viscosity Behavior | Shear-thinning | Shear-thinning and pseudoplastic |

| Applications | Dairy, desserts, beverages, vegan gels | Salad dressings, sauces, gluten-free baking |

| Allergenicity | Generally recognized as safe (GRAS) | Generally recognized as safe (GRAS) |

| Usage Level | Typically 0.01-0.5% | Typically 0.1-0.5% |

Introduction to Gellan Gum and Xanthan Gum

Gellan gum is a water-soluble polysaccharide produced by the bacterium Sphingomonas elodea, widely used as a gelling agent, stabilizer, and thickener in food and pharmaceutical industries. Xanthan gum, derived from the fermentation of glucose or sucrose by Xanthomonas campestris, is valued for its exceptional viscosity and shear-thinning properties, making it a common additive in sauces, dressings, and gluten-free baking. Both gums serve as hydrocolloids but differ in molecular structure and functional characteristics, influencing their specific applications and textures.

Origins and Production Processes

Gellan gum is derived from the bacterium Sphingomonas elodea during a fermentation process, producing a microbial polysaccharide prized for its gelling and stabilizing properties. Xanthan gum originates from the fermentation of glucose or sucrose by the bacterium Xanthomonas campestris, yielding a polysaccharide widely used for thickening and emulsifying. Both gums undergo fermentation-based production but differ in their microbial sources, impacting their texture and application in food and pharmaceuticals.

Chemical Structure Comparison

Gellan gum features a linear anionic polysaccharide structure composed of repeating tetrasaccharide units, including glucose, rhamnose, and glucuronic acid, which forms a strong gel in the presence of divalent cations like calcium. Xanthan gum consists of a cellulose backbone with trisaccharide side chains containing mannose, glucuronic acid, and mannose, giving it high viscosity and shear-thinning properties. Your choice between these gums depends on their distinct molecular architecture affecting gel strength, viscosity, and stability under heat or varying pH conditions.

Textural and Functional Properties

Gellan gum exhibits superior gel strength and clarity compared to xanthan gum, making it ideal for firm gel applications and low-calorie dessert formulations. Xanthan gum provides excellent viscosity and shear-thinning properties, enhancing texture and stability in sauces, dressings, and beverages. Both gums function as effective thickeners and stabilizers, but gellan gum excels in heat and acid stability, whereas xanthan gum offers better freeze-thaw resilience.

Uses in Food and Beverage Industry

Gellan gum is widely used in the food and beverage industry as a gelling agent, stabilizer, and thickener, particularly in dairy products, fruit juices, and plant-based alternatives due to its heat resistance and ability to create smooth textures. Xanthan gum excels as a thickening and stabilizing agent in salad dressings, sauces, and gluten-free baked goods, providing viscosity at low concentrations and maintaining stability across a wide pH and temperature range. Both gums improve product texture and shelf life but are selected based on specific functional requirements like gel strength and freeze-thaw stability.

Applications Beyond Food

Gellan gum and xanthan gum are widely used in pharmaceuticals, cosmetics, and industrial applications due to their unique rheological properties. Gellan gum forms firm gels ideal for controlled-release drug formulations and cosmetic thickeners, while xanthan gum excels as a stabilizer and emulsifier in personal care products and oil drilling fluids. Understanding these differences allows you to select the optimal gum for enhancing product texture and stability beyond food industries.

Nutritional and Allergen Considerations

Gellan gum and xanthan gum are both popular thickeners and stabilizers commonly used in food products, with gellan gum derived from Sphingomonas bacteria and xanthan gum produced by Xanthomonas campestris fermentation. Nutritionally, both gums are low-calorie dietary fibers that do not significantly impact blood sugar levels, making them suitable for diabetic-friendly recipes. Allergen concerns are minimal for both; however, xanthan gum may pose risks for individuals with allergies to corn, soy, or wheat if derived from those substrates, while gellan gum is generally recognized as hypoallergenic.

Impact on Taste and Mouthfeel

Gellan gum imparts a clean, smooth texture with a slightly firmer gel consistency that enhances mouthfeel without overpowering the flavor, making it ideal for clear beverages and low-sugar products. Xanthan gum provides a more viscous, creamy mouthfeel and can sometimes introduce a subtle aftertaste, which may affect the overall sensory profile in products like salad dressings or sauces. Both gums influence texture significantly, but gellan gum is preferred when a neutral taste and a crisp, stable gel are desired, while xanthan gum suits formulations requiring thicker consistency and improved suspension.

Stability Under Different Conditions

Gellan gum demonstrates superior stability across a wide pH range (2-12) and maintains viscosity at elevated temperatures up to 90degC, making it ideal for acidic and heat-processed products. Xanthan gum provides excellent stability in extreme pH levels (2-12) and shear conditions, but its viscosity may decrease under high heat exposure above 80degC. Both gums excel in salt tolerance, yet gellan gum forms more robust gels in the presence of divalent cations, enhancing texture stability in dairy and plant-based formulations.

Choosing the Right Gum for Your Needs

Gellan gum and xanthan gum serve distinct purposes in food and industrial applications, with gellan gum providing superior gel strength and clarity for products like vegan cheese and beverages, while xanthan gum excels in thickening and stabilizing sauces and dressings. Your choice depends on whether you need a firm, heat-stable gel or enhanced viscosity and suspension properties in your formulation. Understanding the specific functional attributes of each gum ensures optimal texture, stability, and performance in your product development.

Gellan Gum vs Xanthan Gum Infographic

libmatt.com

libmatt.com