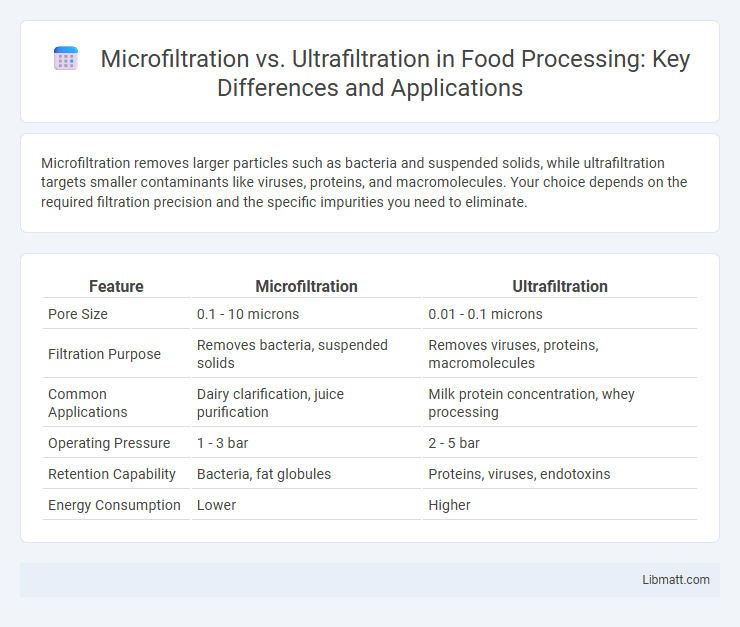

Microfiltration removes larger particles such as bacteria and suspended solids, while ultrafiltration targets smaller contaminants like viruses, proteins, and macromolecules. Your choice depends on the required filtration precision and the specific impurities you need to eliminate.

Table of Comparison

| Feature | Microfiltration | Ultrafiltration |

|---|---|---|

| Pore Size | 0.1 - 10 microns | 0.01 - 0.1 microns |

| Filtration Purpose | Removes bacteria, suspended solids | Removes viruses, proteins, macromolecules |

| Common Applications | Dairy clarification, juice purification | Milk protein concentration, whey processing |

| Operating Pressure | 1 - 3 bar | 2 - 5 bar |

| Retention Capability | Bacteria, fat globules | Proteins, viruses, endotoxins |

| Energy Consumption | Lower | Higher |

Introduction to Membrane Filtration Technologies

Microfiltration and ultrafiltration are key membrane filtration technologies used for separating particles based on size, with microfiltration removing particles typically between 0.1 and 10 microns and ultrafiltration targeting smaller particles ranging from 0.01 to 0.1 microns. Both processes are essential in water treatment, food processing, and biotechnology for clarifying fluids, concentrating proteins, and removing bacteria or viruses. The choice between microfiltration and ultrafiltration depends on the specific application requirements, such as desired pore size, filtration efficiency, and contaminant types.

What is Microfiltration?

Microfiltration is a membrane filtration process that removes particles typically in the range of 0.1 to 10 microns, effectively eliminating bacteria, suspended solids, and large colloids from liquids. It operates under low pressure and is widely used in water treatment, dairy processing, and beverage clarification to improve quality and safety. Your choice of microfiltration ensures the removal of contaminants without affecting essential nutrients or flavor compounds.

Understanding Ultrafiltration

Ultrafiltration is a membrane filtration process that removes particles ranging from 0.01 to 0.1 microns, effectively filtering out viruses, bacteria, and suspended solids. Unlike microfiltration, which targets larger particles between 0.1 and 10 microns, ultrafiltration provides a higher level of purification suitable for applications like water treatment and pharmaceutical processing. The ultrafiltration membrane's tighter pore structure ensures superior contaminant removal, improving product quality and safety.

Key Differences Between Microfiltration and Ultrafiltration

Microfiltration utilizes membrane pores typically ranging from 0.1 to 10 microns, effectively removing suspended solids, bacteria, and large particulates, whereas ultrafiltration features smaller pores between 0.01 to 0.1 microns, targeting viruses, colloids, and macromolecules. Microfiltration operates primarily as a pre-treatment step in water purification systems, while ultrafiltration serves as a more advanced filtration method capable of producing higher water quality by retaining dissolved solids and organic compounds. The pressure requirements differ as well, with microfiltration functioning at lower operating pressures (10-30 psi) compared to ultrafiltration systems requiring higher pressures (20-100 psi) for optimal filtration performance.

Pore Size and Filtration Mechanisms

Microfiltration membranes typically have pore sizes ranging from 0.1 to 10 microns, effectively removing larger particles such as suspended solids and bacteria through size exclusion. Ultrafiltration membranes possess smaller pores, usually between 0.01 to 0.1 microns, enabling the removal of viruses, colloids, and macromolecules via both size exclusion and adsorption mechanisms. These differences in pore size and filtration processes determine the suitability of microfiltration for pre-treatment and ultrafiltration for more refined separation in water and wastewater treatment applications.

Typical Applications of Microfiltration

Microfiltration is commonly used in water treatment to remove suspended solids, bacteria, and algae, making it ideal for municipal water purification and wastewater treatment. It also plays a crucial role in the food and beverage industry by clarifying liquids, such as milk and fruit juices, while preserving essential nutrients. Your operation can benefit from microfiltration's ability to efficiently separate larger particles and microorganisms, ensuring product safety and quality.

Common Uses of Ultrafiltration

Ultrafiltration is widely used for water purification, removing bacteria, viruses, and macromolecules from drinking water and wastewater treatment. It is instrumental in the food and beverage industry for concentrating proteins, dairy products, and clarifying fruit juices. This membrane filtration technique also plays a crucial role in pharmaceutical manufacturing by sterilizing and concentrating bio-products.

Advantages and Limitations of Microfiltration

Microfiltration offers advantages such as lower energy consumption and effective removal of suspended solids, bacteria, and large particles, making it suitable for water treatment and food processing. Its limitations include inability to remove dissolved salts or smaller contaminants like viruses and organic molecules, requiring additional treatment steps for complete purification. Compared to ultrafiltration, microfiltration has larger pore sizes (0.1-10 microns) leading to faster flow rates but reduced filtration precision.

Pros and Cons of Ultrafiltration

Ultrafiltration offers high filtration efficiency by removing particles, bacteria, and viruses as small as 0.01 microns, making it ideal for water purification and wastewater treatment. Its main advantages include improving water clarity and safety without the need for chemical additives, but it requires higher energy consumption and regular membrane cleaning to prevent fouling. Compared to microfiltration, ultrafiltration provides finer filtration but at increased operational costs and maintenance complexity.

Choosing the Right Filtration Method for Your Needs

Microfiltration removes particles between 0.1 to 10 microns, making it ideal for clarifying liquids and removing bacteria, while ultrafiltration targets smaller particles ranging from 0.01 to 0.1 microns, effectively filtering viruses, proteins, and larger molecules. Your choice depends on the required filtration precision, with microfiltration suitable for water treatment and food processing, and ultrafiltration preferred in pharmaceuticals and wastewater treatment for higher contaminant removal. Assess your specific application needs, including particle size and desired purity, to select the filtration method that ensures optimal performance.

Microfiltration vs Ultrafiltration Infographic

libmatt.com

libmatt.com