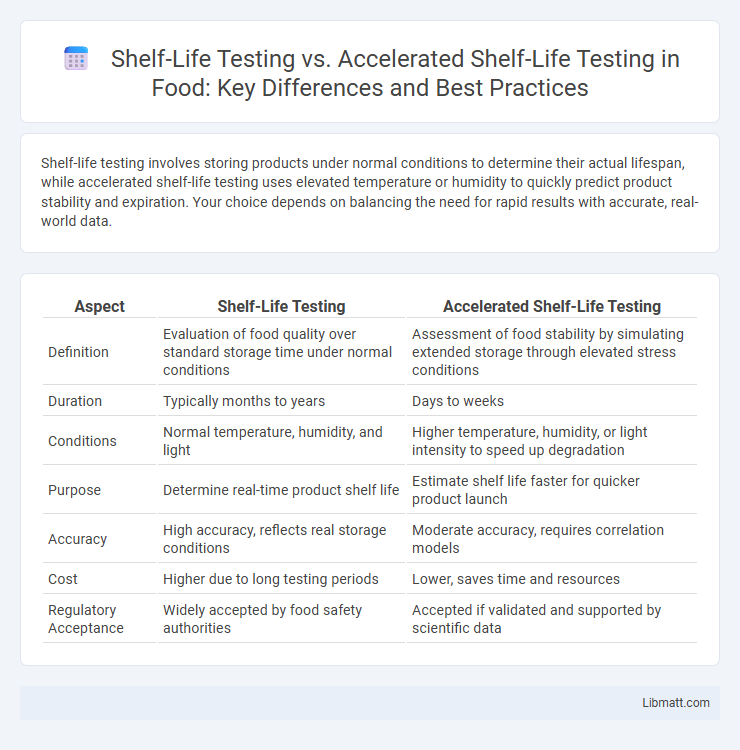

Shelf-life testing involves storing products under normal conditions to determine their actual lifespan, while accelerated shelf-life testing uses elevated temperature or humidity to quickly predict product stability and expiration. Your choice depends on balancing the need for rapid results with accurate, real-world data.

Table of Comparison

| Aspect | Shelf-Life Testing | Accelerated Shelf-Life Testing |

|---|---|---|

| Definition | Evaluation of food quality over standard storage time under normal conditions | Assessment of food stability by simulating extended storage through elevated stress conditions |

| Duration | Typically months to years | Days to weeks |

| Conditions | Normal temperature, humidity, and light | Higher temperature, humidity, or light intensity to speed up degradation |

| Purpose | Determine real-time product shelf life | Estimate shelf life faster for quicker product launch |

| Accuracy | High accuracy, reflects real storage conditions | Moderate accuracy, requires correlation models |

| Cost | Higher due to long testing periods | Lower, saves time and resources |

| Regulatory Acceptance | Widely accepted by food safety authorities | Accepted if validated and supported by scientific data |

Introduction to Shelf-Life Testing

Shelf-life testing evaluates a product's stability, safety, and quality over its intended storage period under normal conditions, providing critical data on expiration dates and optimal usage. Accelerated shelf-life testing simulates long-term aging by exposing products to elevated temperature, humidity, or light, significantly reducing the testing timeline while predicting product durability. Both methods are essential for regulatory compliance, consumer safety, and ensuring consistent product performance in industries like food, pharmaceuticals, and cosmetics.

Understanding Accelerated Shelf-Life Testing

Accelerated shelf-life testing (ASLT) involves subjecting products to elevated stress conditions such as increased temperature, humidity, or light to simulate the aging process and predict product stability within a shorter timeframe than real-time shelf-life testing. Understanding ASLT enables manufacturers to estimate the product's expiration date, optimize formulation, and ensure quality control more efficiently by analyzing degradation kinetics under controlled accelerated conditions. This approach is essential for fast-moving consumer goods, pharmaceuticals, and food industries to maintain safety and regulatory compliance while reducing time-to-market.

Key Differences Between Shelf-Life and Accelerated Shelf-Life Testing

Shelf-life testing involves storing products under normal conditions to observe their quality and safety over time, providing real-time data on product durability. Accelerated shelf-life testing uses elevated stress factors like higher temperature and humidity to simulate aging, allowing faster prediction of product stability. Key differences include time duration, with shelf-life testing taking longer, and predictive accuracy, where accelerated methods estimate but may not fully replicate actual storage conditions.

Importance of Shelf-Life Studies in Product Development

Shelf-life testing provides critical data on product stability under normal storage conditions, ensuring safety, efficacy, and quality throughout its intended lifespan. Accelerated shelf-life testing uses elevated stress factors to predict long-term stability in a shorter period, enabling faster decision-making during product development. Understanding these tests helps you optimize formulations and packaging to meet regulatory requirements and customer expectations.

Methodologies Used in Shelf-Life Testing

Shelf-life testing employs real-time storage conditions to monitor product stability and degradation over the expected lifespan, providing accurate data on deterioration factors such as moisture, microbial growth, and chemical changes. Accelerated shelf-life testing (ASLT) uses elevated temperatures, humidity, or light levels to simulate aging processes rapidly, enabling quicker prediction of product longevity by applying Arrhenius equations or similar kinetic models. Your choice between methodologies depends on the balance of testing time, resource availability, and the precision of shelf-life estimates needed for regulatory compliance or quality assurance.

Advantages of Accelerated Shelf-Life Testing

Accelerated shelf-life testing offers significant advantages by rapidly predicting a product's stability and expiration under controlled stress conditions, saving valuable time and resources compared to traditional methods. This approach enables faster decision-making for product formulation and packaging, helping ensure Your product meets safety and quality standards before market release. It also allows for early detection of potential degradation pathways, improving overall product reliability and customer satisfaction.

Limitations and Challenges of Accelerated Shelf-Life Testing

Accelerated shelf-life testing often struggles with accurately mimicking natural degradation processes, leading to potential discrepancies in predicting actual product lifespan under normal storage conditions. Elevated temperatures and stresses can induce chemical reactions and physical changes not typically present during real-time storage, complicating the extrapolation of results. Furthermore, formulation complexity and product variability pose significant challenges in standardizing accelerated testing protocols for reliable shelf-life determination.

Factors Affecting Shelf-Life Determination

Shelf-life determination is influenced by intrinsic product factors such as composition, pH, moisture content, and packaging materials that affect microbial growth and chemical stability. Environmental conditions like temperature, humidity, and light exposure play a critical role in both standard and accelerated shelf-life testing by accelerating degradation reactions. Accelerated shelf-life testing uses elevated stress conditions to predict product stability over time, but accurate modeling requires understanding the kinetics of deterioration under these specific factors.

Regulatory Considerations for Shelf-Life Testing

Regulatory considerations for shelf-life testing emphasize the need to validate product stability under intended storage conditions, ensuring compliance with guidelines from agencies like the FDA and EMA. Accelerated shelf-life testing must be correlated to real-time data to accurately predict product behavior and maintain regulatory acceptance. Proper documentation and adherence to established protocols are critical for both methods to support product registration and market approval.

Choosing the Right Testing Approach for Your Product

Choosing the right testing approach for your product depends on factors such as product type, storage conditions, and time constraints. Shelf-life testing involves real-time monitoring under normal storage conditions to accurately determine product stability over its intended lifespan. Accelerated shelf-life testing uses elevated stress conditions like increased temperature or humidity to quickly predict product longevity, enabling faster decision-making during development.

shelf-life testing vs accelerated shelf-life testing Infographic

libmatt.com

libmatt.com