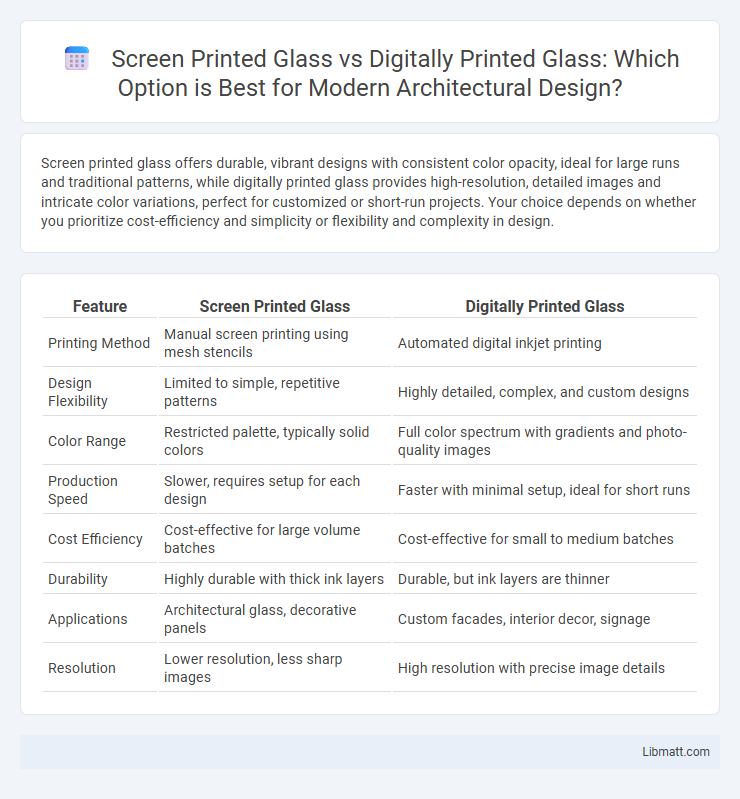

Screen printed glass offers durable, vibrant designs with consistent color opacity, ideal for large runs and traditional patterns, while digitally printed glass provides high-resolution, detailed images and intricate color variations, perfect for customized or short-run projects. Your choice depends on whether you prioritize cost-efficiency and simplicity or flexibility and complexity in design.

Table of Comparison

| Feature | Screen Printed Glass | Digitally Printed Glass |

|---|---|---|

| Printing Method | Manual screen printing using mesh stencils | Automated digital inkjet printing |

| Design Flexibility | Limited to simple, repetitive patterns | Highly detailed, complex, and custom designs |

| Color Range | Restricted palette, typically solid colors | Full color spectrum with gradients and photo-quality images |

| Production Speed | Slower, requires setup for each design | Faster with minimal setup, ideal for short runs |

| Cost Efficiency | Cost-effective for large volume batches | Cost-effective for small to medium batches |

| Durability | Highly durable with thick ink layers | Durable, but ink layers are thinner |

| Applications | Architectural glass, decorative panels | Custom facades, interior decor, signage |

| Resolution | Lower resolution, less sharp images | High resolution with precise image details |

Overview of Screen Printed Glass

Screen printed glass utilizes ceramic-based inks applied through a mesh screen, resulting in durable and opaque designs ideal for architectural and decorative purposes. This method ensures precise color layering with excellent resistance to UV fading and abrasion. You can achieve consistent, high-quality patterns suited for both interior and exterior glass applications.

Overview of Digitally Printed Glass

Digitally printed glass offers high-resolution, full-color images directly applied onto glass surfaces using advanced inkjet technology, providing intricate designs and photorealistic quality that traditional screen printing cannot achieve. This method allows for greater customization, faster production times, and the ability to print variable data without the need for screens or stencils. Your projects benefit from increased design flexibility and vibrant, durable prints that are ideal for architectural, decorative, and commercial glass applications.

Key Differences Between the Two Printing Methods

Screen printed glass uses stencils and mesh screens to apply ceramic inks, resulting in durable, opaque designs best suited for large patterns and long runs. Digitally printed glass employs inkjet technology to print variable, high-resolution images directly onto the glass, offering greater design flexibility and finer detail for short runs or custom projects. The key differences lie in durability, color vibrancy, and cost-efficiency depending on project scale and complexity.

Print Quality and Design Flexibility

Screen printed glass offers consistent color density and sharp edges due to its stencil-based technique, delivering high durability ideal for repetitive patterns and large-scale applications. Digitally printed glass provides superior design flexibility with the ability to reproduce complex, multi-colored images and gradients directly onto surfaces, enabling customized and intricate artwork. Print quality in digital methods varies with printer resolution and ink technology, allowing for detailed, photo-realistic visuals unattainable through traditional screen printing.

Durability and Performance Comparison

Screen printed glass offers exceptional durability due to its thick ceramic inks fused onto the surface during high-temperature curing, making it resistant to scratches, UV fading, and harsh weather conditions. Digitally printed glass uses advanced pigmented inks that provide high-resolution imagery with excellent color vibrancy, but its durability depends on additional protective coatings and curing processes to ensure long-term wear resistance. Your choice between screen printed and digitally printed glass should consider the specific environmental exposure and performance requirements to achieve optimal longevity and aesthetic appeal.

Applications and Industry Uses

Screen printed glass excels in architectural applications such as facades, partitions, and decorative panels due to its durability and ability to produce large, consistent patterns. Digitally printed glass is preferred in customized interior design, retail displays, and signage where high-resolution images and complex color gradients are required. Your choice depends on the project scale and the desired visual complexity, with screen printing favored in industrial settings and digital printing dominating bespoke, detailed applications.

Cost Considerations

Screen printed glass typically incurs lower initial costs for large-scale production due to the use of reusable screens and simpler technology. Digitally printed glass offers cost efficiency for small runs and custom designs by eliminating screen creation expenses and reducing setup time. Choosing between the two depends on production volume and design complexity, with screen printing favoring high-volume projects and digital printing better suited for customization.

Environmental Impact and Sustainability

Screen printed glass involves ceramic inks fired at high temperatures, resulting in durable surfaces but generating significant energy consumption and waste during the process. Digitally printed glass uses UV-curable or solvent-based inks with minimal waste and lower energy requirements, enhancing its sustainability profile. The reduced material usage and ability to print on-demand make digitally printed glass a more environmentally friendly option compared to traditional screen printing.

Choosing the Right Printing Method for Your Project

Screen printed glass offers vibrant colors and durability, making it ideal for large-scale projects requiring consistent opacity and texture. Digitally printed glass provides high-resolution, full-color artwork with intricate designs, perfect for customization and detailed imagery in smaller runs. Selecting the right method depends on project scale, budget constraints, and the desired visual impact.

Future Trends in Glass Printing Technologies

Future trends in glass printing technologies emphasize advancements in both screen printed glass and digitally printed glass, with a notable shift toward higher resolution, faster production speeds, and environmentally sustainable processes. Digitally printed glass is rapidly gaining traction due to its ability to produce complex, customizable designs with precise color control and minimal waste, making it ideal for architectural and automotive applications. Your investment in digital printing technology ensures access to innovative features like UV curing and smart coatings that enhance durability and energy efficiency, positioning your projects at the forefront of modern glass design.

screen printed glass vs digitally printed glass Infographic

libmatt.com

libmatt.com