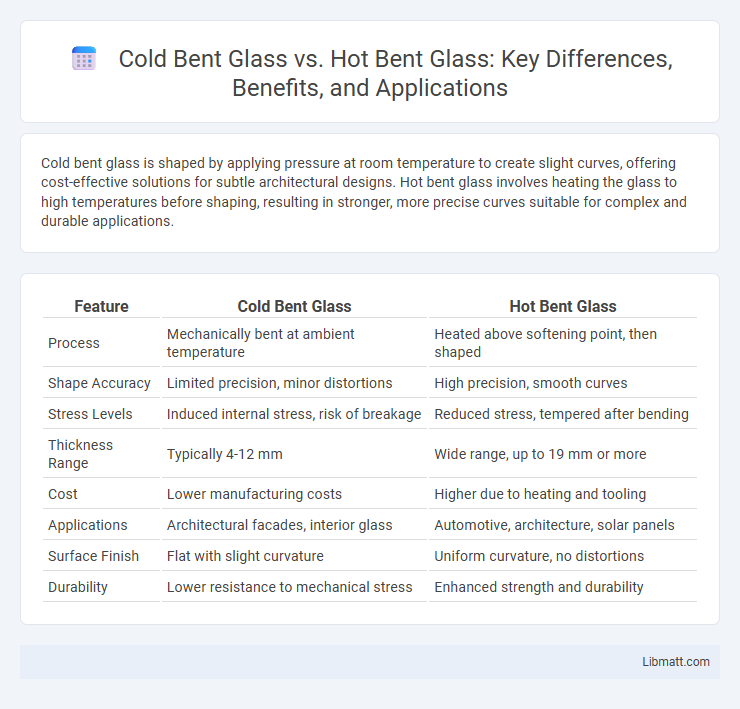

Cold bent glass is shaped by applying pressure at room temperature to create slight curves, offering cost-effective solutions for subtle architectural designs. Hot bent glass involves heating the glass to high temperatures before shaping, resulting in stronger, more precise curves suitable for complex and durable applications.

Table of Comparison

| Feature | Cold Bent Glass | Hot Bent Glass |

|---|---|---|

| Process | Mechanically bent at ambient temperature | Heated above softening point, then shaped |

| Shape Accuracy | Limited precision, minor distortions | High precision, smooth curves |

| Stress Levels | Induced internal stress, risk of breakage | Reduced stress, tempered after bending |

| Thickness Range | Typically 4-12 mm | Wide range, up to 19 mm or more |

| Cost | Lower manufacturing costs | Higher due to heating and tooling |

| Applications | Architectural facades, interior glass | Automotive, architecture, solar panels |

| Surface Finish | Flat with slight curvature | Uniform curvature, no distortions |

| Durability | Lower resistance to mechanical stress | Enhanced strength and durability |

Introduction to Bent Glass Technologies

Bent glass technologies include cold bent glass, which is shaped by mechanical force at room temperature, and hot bent glass, formed by heating the glass until pliable and then molding it into curves. Cold bent glass maintains the original temper and strength but is limited in the degree of curvature achievable, while hot bent glass allows more complex shapes with a smooth, uniform curve but requires specialized kilns and cooling processes. Understanding these differences helps you select the appropriate bent glass method for architectural or automotive applications based on design complexity and structural requirements.

Overview: Cold Bent Glass vs Hot Bent Glass

Cold bent glass involves manually flexing flat glass into a slight curve within a frame without heating, preserving its original strength while allowing subtle bends ideal for smaller architectural applications. Hot bent glass is heated in a kiln until it becomes pliable and then shaped into precise curves, resulting in smooth, complex designs with enhanced structural integrity suited for large-scale facades or artistic installations. Your choice depends on the curvature complexity, budget, and application requirements, with hot bent glass offering greater customization and cold bent glass providing cost-effective flexibility.

Manufacturing Processes Compared

Cold bent glass involves mechanically bending flat glass sheets at room temperature using specialized framing systems, allowing for flexible shapes without altering the glass's inherent properties. Hot bent glass is produced by heating the glass to its softening point, then molding it into desired curved forms, resulting in permanent shapes with enhanced structural integrity. Your choice between these methods depends on project requirements for curvature precision, structural strength, and budget constraints.

Material Properties and Structural Performance

Cold bent glass maintains its original strength and clarity since it is shaped without heat, preserving the inherent material properties such as high tensile strength and resistance to impact. Hot bent glass undergoes thermal tempering during bending, which improves structural performance by increasing surface compressive stresses, enhancing its load-bearing capacity and resistance to thermal stress. Your choice between cold and hot bent glass affects durability and safety, with hot bent glass offering superior structural resilience for demanding architectural applications.

Design Flexibility and Architectural Applications

Cold bent glass offers greater design flexibility through subtle curves achieved by bending flat glass panels within a frame, ideal for applications requiring gentle, adjustable shapes without heat treatment. Hot bent glass, formed by heating the glass to high temperatures and molding it into precise, complex curves, enables architects to realize bold, intricate designs such as double curvature facades and sculptural elements. The choice between cold and hot bent glass depends on project requirements for curvature accuracy, cost constraints, and desired aesthetic impact in architectural applications.

Aesthetic Differences and Visual Impact

Cold bent glass maintains a flat appearance with subtle curvature achieved under tension, resulting in sharper reflections and a more uniform light distribution that enhances modern, angular architectural designs. Hot bent glass offers smooth, continuous curves formed through heat, producing softer visual transitions and distorted reflections that add depth and organic fluidity to facades. The aesthetic impact of cold bent glass emphasizes precision and geometric clarity, whereas hot bent glass introduces warmth and dynamic visual complexity.

Cost Implications and Production Efficiency

Cold bent glass typically incurs lower initial costs due to simpler production processes and decreased energy consumption, making it more cost-effective for projects with tight budgets. Hot bent glass requires specialized furnaces and longer production times, resulting in higher material and labor expenses but offers superior shape precision and durability. Production efficiency favors cold bent glass for standard applications requiring quick turnaround, while hot bent glass suits complex, custom designs despite its slower, more resource-intensive manufacturing.

Energy Efficiency and Sustainability

Cold bent glass reduces energy consumption during installation by eliminating the need for thermal treatment, contributing to lower overall environmental impact. Hot bent glass offers enhanced energy efficiency in buildings through precise curvature that improves thermal insulation and reduces heat loss. Sustainable building designs leverage hot bent glass for its durability and performance, while cold bent glass minimizes carbon footprint by avoiding the intense energy demands of heat bending processes.

Installation Challenges and Considerations

Cold bent glass requires careful handling during installation to avoid stress points since it is bent on-site without heating, making it susceptible to breakage if misaligned. Hot bent glass, pre-shaped in a controlled environment, offers uniform curvature, reducing the risk of stress fractures but demands precise measurements and framing to accommodate its fixed shape. Your choice impacts installation complexity, with cold bent glass allowing some flexibility but necessitating experienced installers to manage potential warping and hot bent glass needing exact preparation to fit permanent structural elements.

Choosing the Right Solution: Factors to Consider

Choosing between cold bent glass and hot bent glass depends on factors such as project complexity, budget, and desired aesthetic. Cold bent glass is cost-effective and suitable for slight curvature without distortion, while hot bent glass offers precise, complex shapes with enhanced structural integrity but at a higher cost. Consider installation requirements, thermal performance, and durability to determine the optimal solution for architectural and design needs.

cold bent glass vs hot bent glass Infographic

libmatt.com

libmatt.com