Tempered glass offers high strength and shatters into small, blunt pieces for safety, making it ideal for areas prone to impact, while laminated glass consists of two or more layers bonded with an interlayer that holds shards together when broken, providing enhanced security and sound insulation. Your choice depends on whether impact resistance or safety against breakage and noise reduction is more critical for your application.

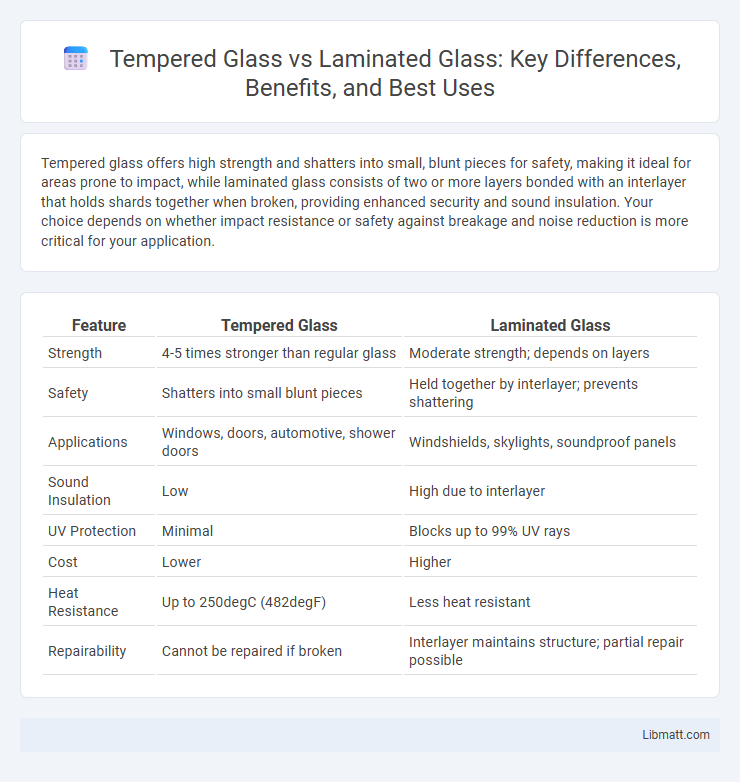

Table of Comparison

| Feature | Tempered Glass | Laminated Glass |

|---|---|---|

| Strength | 4-5 times stronger than regular glass | Moderate strength; depends on layers |

| Safety | Shatters into small blunt pieces | Held together by interlayer; prevents shattering |

| Applications | Windows, doors, automotive, shower doors | Windshields, skylights, soundproof panels |

| Sound Insulation | Low | High due to interlayer |

| UV Protection | Minimal | Blocks up to 99% UV rays |

| Cost | Lower | Higher |

| Heat Resistance | Up to 250degC (482degF) | Less heat resistant |

| Repairability | Cannot be repaired if broken | Interlayer maintains structure; partial repair possible |

Introduction to Tempered Glass and Laminated Glass

Tempered glass undergoes a heat treatment process that increases its strength and causes it to break into small, blunt pieces for safety, making it ideal for applications requiring impact resistance. Laminated glass consists of two or more glass layers bonded with an interlayer, enhancing its ability to hold together when shattered and providing superior sound insulation and UV protection. Both types of glass offer unique structural benefits tailored to safety and durability in architectural and automotive industries.

Composition and Manufacturing Processes

Tempered glass is produced through a rapid heating and cooling process that strengthens the outer surfaces while maintaining a tensioned core, typically composed of annealed float glass heated to around 620degC and rapidly cooled. Laminated glass consists of two or more layers of glass bonded together with an interlayer, usually polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), under heat and pressure to enhance safety and sound insulation. The manufacturing of laminated glass involves stacking the glass layers with the interlayer sandwiched between them, then passing through an autoclave to achieve a durable, impact-resistant composite structure.

Strength and Durability Comparison

Tempered glass offers high strength due to its heat treatment process, making it up to five times stronger than standard glass and highly resistant to impact and thermal stress. Laminated glass combines two or more glass layers with an interlayer, providing excellent durability by holding shards together upon impact, enhancing safety even if it breaks. Your choice depends on the need for impact resistance with shatterproof safety (laminated) or maximum strength and thermal resistance (tempered).

Safety Features and Breakage Patterns

Tempered glass, known for its safety features, shatters into small, blunt granules that reduce injury risks, making it ideal for automotive windows and shower enclosures. Laminated glass consists of two or more glass layers bonded by an interlayer, which holds shards in place upon breakage, providing superior protection against penetration and impact. Its breakage pattern ensures structural integrity, commonly used in windshields and skylights where safety and security are critical.

Acoustic and Thermal Insulation Properties

Tempered glass offers moderate acoustic insulation but less effective thermal insulation compared to laminated glass, which contains an interlayer that enhances sound absorption and prevents heat transfer. Laminated glass significantly reduces noise pollution by dampening sound vibrations, making it ideal for environments requiring superior acoustic comfort. Its interlayer also improves thermal performance by minimizing heat loss and blocking UV rays, contributing to energy efficiency in buildings.

Applications in Architecture and Automotive Industries

Tempered glass offers superior strength and shatters into small, blunt pieces, making it ideal for automotive windows and architectural elements requiring safety and impact resistance, such as doors and facades. Laminated glass consists of two or more layers bonded with an interlayer, providing enhanced security, sound insulation, and UV protection, commonly used in skylights, curtain walls, and windshields. Your choice between tempered and laminated glass will depend on the specific safety requirements and functional benefits needed for automotive or architectural applications.

Cost Differences and Affordability

Tempered glass generally costs less than laminated glass due to simpler manufacturing processes and fewer material layers involved. Laminated glass, which includes a plastic interlayer for enhanced safety and sound insulation, tends to be more expensive but offers greater durability and security. Your choice between the two should balance budget constraints with the requirement for impact resistance and safety features.

Maintenance and Longevity

Tempered glass requires minimal maintenance due to its high resistance to scratches and impacts, ensuring a longer lifespan even in high-traffic areas. Laminated glass, with its interlayer bonding, not only enhances safety but also offers durability against cracks and UV damage, extending its usability over time. Your choice between tempered and laminated glass should consider these factors for optimal maintenance ease and long-term performance.

Environmental Impact and Recyclability

Tempered glass is highly recyclable due to its uniform composition but requires energy-intensive processing to achieve its strength, impacting its environmental footprint. Laminated glass, composed of multiple layers with polymer interlayers, poses recycling challenges as the separation process is complex, often leading to downcycling rather than true recycling. Your choice between tempered and laminated glass influences sustainability outcomes, with tempered glass offering better recyclability while laminated glass enhances safety with potential trade-offs in environmental impact.

Which Glass Type is Best for Your Needs?

Tempered glass offers superior strength and shatters into small, blunt pieces, making it ideal for safety in high-impact areas like car windows and shower doors. Laminated glass consists of two panes bonded with a plastic interlayer, providing increased security and sound insulation, perfect for windows exposed to break-in risks or noise pollution. Your choice depends on whether you prioritize impact resistance and safety or enhanced protection and noise reduction.

tempered glass vs laminated glass Infographic

libmatt.com

libmatt.com