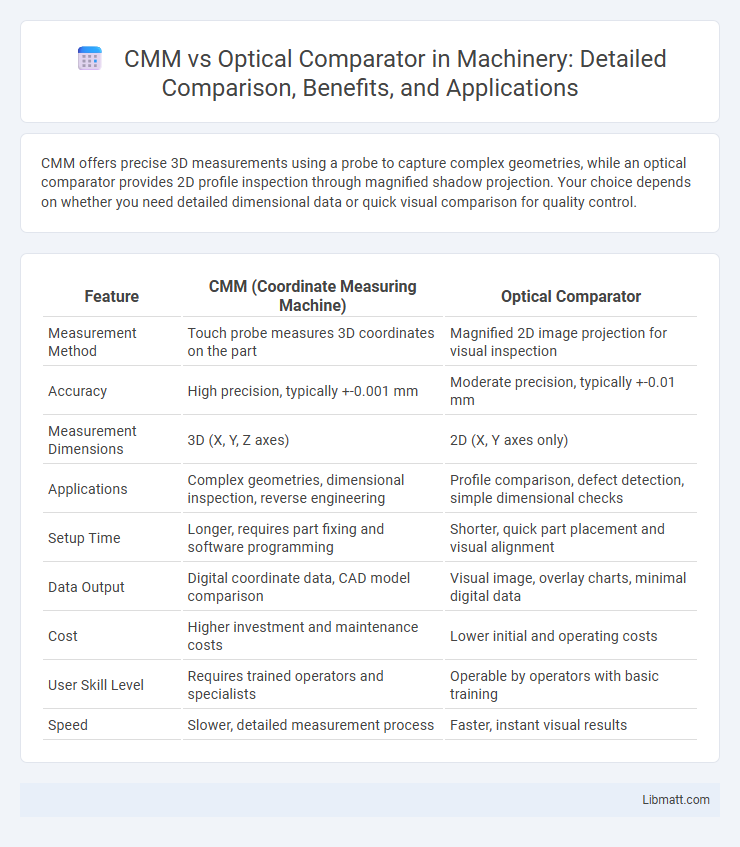

CMM offers precise 3D measurements using a probe to capture complex geometries, while an optical comparator provides 2D profile inspection through magnified shadow projection. Your choice depends on whether you need detailed dimensional data or quick visual comparison for quality control.

Table of Comparison

| Feature | CMM (Coordinate Measuring Machine) | Optical Comparator |

|---|---|---|

| Measurement Method | Touch probe measures 3D coordinates on the part | Magnified 2D image projection for visual inspection |

| Accuracy | High precision, typically +-0.001 mm | Moderate precision, typically +-0.01 mm |

| Measurement Dimensions | 3D (X, Y, Z axes) | 2D (X, Y axes only) |

| Applications | Complex geometries, dimensional inspection, reverse engineering | Profile comparison, defect detection, simple dimensional checks |

| Setup Time | Longer, requires part fixing and software programming | Shorter, quick part placement and visual alignment |

| Data Output | Digital coordinate data, CAD model comparison | Visual image, overlay charts, minimal digital data |

| Cost | Higher investment and maintenance costs | Lower initial and operating costs |

| User Skill Level | Requires trained operators and specialists | Operable by operators with basic training |

| Speed | Slower, detailed measurement process | Faster, instant visual results |

Introduction to CMM and Optical Comparator

Coordinate Measuring Machines (CMM) use precise probes and advanced software to measure the physical geometrical characteristics of an object, providing detailed 3D data for quality control and inspection. Optical Comparators, also known as profile projectors, utilize magnified images and overlay grids to compare measured parts against design specifications, primarily used for 2D measurements and visual inspection. Both instruments play critical roles in manufacturing, with CMMs excelling in 3D precision and Optical Comparators offering fast, non-contact inspection for surface features.

How CMMs Work: Principles and Process

Coordinate Measuring Machines (CMMs) operate by using a probe to touch multiple points on an object's surface, capturing precise 3D coordinates to create an accurate digital representation. These machines employ sensors such as tactile, optical, or laser to measure dimensions, distances, and geometric features with high accuracy and repeatability. The data collected is processed through advanced software that analyzes, compares, and verifies part conformity against design specifications in manufacturing quality control.

Optical Comparator Fundamentals Explained

An optical comparator projects magnified shadow images of parts onto a screen, allowing precise measurement of profile and dimensional features through visual comparison and overlay of templates. This tool excels in inspecting complex shapes and small features non-contactly, ensuring high accuracy for quality control without physical probing. Your choice between a Coordinate Measuring Machine (CMM) and an optical comparator depends on the need for 3D measurement versatility versus detailed 2D profile analysis.

Key Differences Between CMM and Optical Comparator

Coordinate Measuring Machines (CMM) utilize tactile probes to precisely measure the physical dimensions of objects in three-dimensional space, while optical comparators employ magnified visual projection to compare part profiles against standards. CMMs offer higher accuracy and the ability to measure complex geometries with automated data collection, whereas optical comparators are typically limited to 2D measurements and rely on operator interpretation. Your choice depends on the required measurement precision, complexity of parts, and inspection speed.

Accuracy and Precision: CMM vs Optical Comparator

Coordinate Measuring Machines (CMM) typically offer higher accuracy and precision compared to optical comparators, with CMMs achieving measurement accuracies in the range of +-1 to +-2 microns, while optical comparators generally provide accuracies around +-5 to +-10 microns. CMMs use tactile probing and sophisticated software algorithms to capture detailed 3D geometric data, enabling precise dimensional measurement and repeatability. Optical comparators rely on magnified 2D shadow images, which can introduce errors due to operator interpretation and lower resolution, limiting their precision for complex or high-tolerance parts.

Applications and Use Cases

Coordinate Measuring Machines (CMM) excel in precise 3D measurements and complex geometries, making them ideal for quality control in aerospace, automotive, and manufacturing industries. Optical comparators are best suited for inspecting small, flat parts with simple profiles in electronics, watchmaking, and tool manufacturing due to their quick 2D measurement capabilities. Your choice depends on whether you need intricate 3D dimensional analysis or rapid 2D profile verification.

Advantages and Limitations of CMMs

Coordinate Measuring Machines (CMMs) offer high precision and automated 3D measurements, enabling complex geometries to be accurately inspected with minimal operator influence and improved repeatability. Their ability to integrate with CAD software and perform non-contact or tactile measurements enhances efficiency in quality control processes. However, CMMs tend to have higher initial costs, require skilled operators, and may be less effective for inspecting large or highly reflective surfaces compared to optical comparators.

Pros and Cons of Optical Comparators

Optical comparators offer high-precision visual inspection with fast, non-contact measurement and are ideal for small to medium-sized parts with complex profiles. They provide clear magnified images that facilitate quick dimensional analysis, but their accuracy is limited compared to CMMs, especially for 3D measurements and large, complex geometries. Optical comparators are less versatile than CMMs, as they rely heavily on operator skill and are generally unsuitable for automated, high-volume inspection in advanced manufacturing environments.

Cost Comparison: Investment and Maintenance

Coordinate Measuring Machines (CMMs) typically require a higher initial investment compared to optical comparators due to advanced technology and automation capabilities. Maintenance costs for CMMs can also be significant, involving periodic calibration and software updates, whereas optical comparators generally incur lower upkeep expenses with simpler mechanical components. You should consider the total cost of ownership, balancing upfront costs against long-term operational efficiency when choosing between these precision measurement tools.

Choosing the Right Measurement Tool for Your Needs

Choosing between a Coordinate Measuring Machine (CMM) and an optical comparator depends on the required precision, complexity, and type of measurement tasks. CMMs offer high accuracy and flexibility for 3D measurements of complex geometries, making them ideal for quality control in advanced manufacturing. Optical comparators provide quick, 2D profile inspections with lower setup time, best suited for dimensioning simpler parts or production line inspections.

CMM vs optical comparator Infographic

libmatt.com

libmatt.com